Abstract

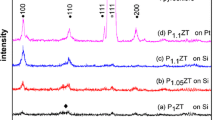

(100) Oriented Pb x Sr1−x TiO3 (PSTO) thin films are prepared on indium tin oxide (ITO)/glass substrates by sol–gel technique while inserting doped PbTiO3 (PTO)-inducing layer in between. The effect of tensile stress in PSTO on tunability and (100) orientation of the thin films was investigated using X-ray diffraction, scanning electron microscopy, transmission electron microscope, and atomic force microscope, respectively. Results show that PSTO thin film deposited on doped PTO has (100) oriented structure while it is randomly oriented when deposited directly on the ITO/glass substrate. Lattice mismatch between PSTO and PTO appears, in which the in-plane lattice constant c is 0.3922–0.3924 nm in the former and 4.02–4.07 nm in the latter, respectively, contributing tensile stress in the PSTO due to different lattice constants between them. The stress in the PSTO thin film is 3.04, 3.15, 3.59 and 4.47 GPa when the doped PTOs are Fe–PTO, Tb–PTO, Co–PTO and Zn–PTO, respectively. The orientation degrees of PSTO thin films are from 89.63, 90.31, 91.92 to 93.29 % with increasing stress of PSTO on Fe–PTO, Tb–PTO, Co–PTO and Zn–PTO, respectively. Tunabilities of the well-oriented PSTO thin films increase in ascending order of 63 < 65 < 69 < 73 % when induced by oriented PTO layers of Fe–PTO, Tb–PTO, Co–PTO and Zn–PTO, respectively, which is in accordance with the degree of (100) orientation appearing in the thin films. The high tunability appears in the PSTO thin film while high (100) orientation is derived from the tensile stress. It is much higher than that of randomly oriented PSTO thin film.

Similar content being viewed by others

References

X.T. Li, W.L. Huo, C.L. Mak, S. Sui, W.J. Weng, G.R. Han, G. Shen, P.Y. Du, Mater. Chem. Phys. 108, 417 (2008)

D.Y. Wang, Y.L. Cheng, J. Wang, X.Y. Zhou, H.L.W. Chan, C.L. Choy, Appl. Phys. A 81, 1607 (2005)

F.F. Guo, B. Yang, S.T. Zhang, D.Q. Liu, F.M. Wu, D.L. Wang, W.W. Cao, Appl. Surf. Sci. 283, 759 (2013)

T. Li, G. Wang, D. Remiens, X. Dong, Ceram. Int. 39, 1359 (2013)

C.A. Vasilescu, M. Crisan, A.C. Ianculescu, M. R˘aileanu, M. Gartner, M. Anastasescu, N. Dr˘agan, D. Crisan, R. Gavril˘a, R. Trus¸c˘a, Appl. Surf. Sci. 265, 510 (2013)

X.T. Li, P.Y. Du, C.L. Mak, K.H. Wong, Appl. Phys. Lett. 90, 262906 (2007)

S.N. Son, L.N. Gao, J.W. Zhai, X. Yao, Z.Q. Cheng, Appl. Surf. Sci. 254, 5120 (2008)

J. Singha, S.B. Krupanidhib, Appl. Surf. Sci. 257, 2214 (2011)

S.W. Liu, J. Chakhalian, M. Xiao, C.L. Chen, Appl. Phys. Lett. 90, 042901 (2007)

Z. Zheng, Y.Y. Yao, W.J. Weng, G.R. Han, N. Ma, P.Y. Du, Thin Solid Films 520, 2717 (2012)

Z. Zheng, Y.Y. Yao, W.J. Weng, G.R. Han, N. Ma, P.Y. Du, J. Mater. Chem. 21, 10808 (2011)

Z. Zheng, T. Hu, Y.Y. Yao, W.J. Weng, G.R. Han, N. Ma, P.Y. Du, J. Alloys Compd. 576, 121 (2013)

P.Y. Du, L.W. Tang, X.H. Zhao, W.J. Weng, G.R. Han, Surf. Coat. Technol. 198, 395 (2005)

K. Li, X.L. Dong, D. Remiens, X.Y. Lei, T. Li, G. Du, G.S. Wang, J. Am. Ceram. Soc. 96, 1682 (2013)

X.Y. Lei, D. Remiens, N. Sama, Y. Chen, C.L. Mao, X.L. Dong, G.S. Wang, J. Cryst. Growth 347, 15 (2012)

Y.K. Kim, S.S. Kim, H. Shin, S. Baik, Appl. Phys. Lett. 84, 5085 (2004)

R.G. Toro, G. Malandrino, I.L. Fragala, W. Keshu, A. Leto, G. Pezzotti, J. Phys. Chem. B 110, 23977 (2006)

W. Zhang, X.G. Tang, K.H. Wong, H.L.W. Chan, Scripta Mater. 54, 197 (2006)

J.F. Chen, P.Y. Du, Y. Qin, G.R. Han, W.J. Weng, Thin Solid Films 516, 5300 (2008)

J.G. Wu, D.Q. Xiao, Y.Y. Wang, J.G. Zhu, J.L. Zhu, R.S. Xie, J. Am. Ceram. Soc. 91, 3786 (2008)

Z. Zheng, Y.Y. Yao, W.J. Weng, G.R. Han, N. Ma, P.Y. Du, J. Appl. Phys. 93, 124107 (2011)

Acknowledgments

This work is financially supported by Zhejiang Provincial Natural Science Foundation (Grant No. Z4110040) and Natural Science Foundation of China (Grant No. 51172202) respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, T., Fu, H., Zheng, Z. et al. Control of tensile stress on inducing formation and tunability of (100) oriented Pb x Sr1−x TiO3 thin films. Appl. Phys. A 117, 1171–1177 (2014). https://doi.org/10.1007/s00339-014-8490-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-014-8490-4