Abstract

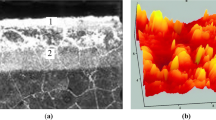

Changes of microstructure, chemical and phase compositions in thin surface layers of low carbon steel saturated by chromium oxide have been studied by TEM, XPS and XRD methods. Ultrafine chromium oxide powder was spread on a steel surface and subjected to laser processing with nanosecond pulses. It was found that such conditions of processing as overheating of small volume of metal, high temperature gradient, rapid solidification and laser-induced plasma formation lead to dissolution of chromium oxide in the metal matrix. As a result of laser processing the surface layers contain chromium oxide, chrome-spinel FeO\(\cdot \)Cr\(_{2}\)O\(_{3}\) and chromium in metal state dispersed in alpha and gamma iron. The processing technique allows to obtain surface layers whose chemical composition might be equivalent to the composition of stainless steels.

Similar content being viewed by others

References

E.E. Stansbury, E.E. Buchanan, Fundamentals of Electrochemical Corrosion, 1st edn. (ASM International, New York, 2000)

N.D. Tomashov, Theory of Corrosion and Protection of Metals (Akad. Nauk SSSR, Moscow, 1960)

L.L. Shrier, Corrosion, 1st edn. (Butterworths, London, 1977)

A.M. Huntz, Math. Sci. Eng. A 121, 555 (1989)

S. Beauvais-Reveillon et al., Oxid. Met. 43, 3–4 (1995)

J. Tuominen et al., J. Therm. Spray Technol. 11, 2 (2002)

P.S. Robbert, H. Geisler, C.A. Ventrice Jr, J. van Ek, S. Chaturvedi, J.A. Rodriguez, M. Kuhn, U. Diebold, J. Vac. Sci. Technol. A16, 990 (1998)

T. Maruyama, H. Akagi, J. Electrochem. Soc. 143 (1996)

N. Popovici, M.L. Parames, R.C. Da Silva, O. Monnereau, P.M. Sousa, A.J. Silvestre, O. Conde, Appl. Phys. A 79, 1409–1411 (2004)

E.V. Kharanzhevskiy, M.D. Krivilyov, Phys. Met. Metallogr. 111, 1 (2011)

S.N. Kostenkov, E.V. Kharanzhevskii, M.D. Krivilev, Phys. Met. Metallogr. 113, 1 (2012)

J.P. Kruth, L. Froyen, J. Van Vaerenbergh et al., J. Mater. Process. Technol. 149 (2004)

V.D. Sadovskiy, L.V. Smirnov, V.M. Schastlivtsev et al., Phys. Met. Metallogr. 65, 1 (1989)

V.M. Schastlivtsev, T.I. Tabatchikova, I.L. Yakovleva et al., Phys. Met. Metallogr. 84, 4 (1997)

T.I. Tabatchikova, Phys. Met. Metallogr. 84, 4 (1997)

E.V. Haranzhevskii, D.A. Danilov, M.D. Krivilyov, P.K. Galenko, Mater. Sci. Eng. A, 375–377 (2004)

Y.Y. Andreev, I.A. Safonov, A.V. Doub, Prot. Met. Phys. Chem. Surf. 46, 5 (2010)

Acknowledgments

This study is financially supported by the program 07.08 “Applied Research in Education” of the Ministry of Education and Science of Russia (2.947.2011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kharanzhevskiy, E., Reshetnikov, S. Chromium oxide dissolution in steels via short pulse laser processing. Appl. Phys. A 115, 1469–1477 (2014). https://doi.org/10.1007/s00339-013-8064-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-013-8064-x