Abstract

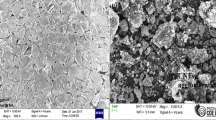

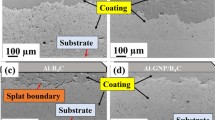

The effect of laser melting on the microstructure and mechanical properties of plasma-sprayed aluminum oxide composite coating reinforced with 4 wt% multi-walled carbon nanotubes (CNTs) is reported. Laser-melted layer consists of dense, coarse columnar microstructure which is significantly different from plasma-sprayed coating that consists of splats and porosity. CNTs retained their original cylindrical graphitic structure after undergoing laser irradiation. Three dimensional heat flow model has been developed to estimate temperature variation in the laser-melted composite layer. Laser-melted layers show an increase in the microhardness at the expanse of degradation of fracture toughness. Nanoindentation study indicates an increase in the elastic modulus and yield strength of the laser-melted layer which is attributed to dense microstructure with absence of weak-bonding splats and porosity.

Similar content being viewed by others

References

R.J. Brook, Concise Encyclopedia of Advanced Ceramic Materials (Pergamon, Elmsford, 1991)

R. Krishnan, S. Dash, C.B. Rao, R.V.S. Rao, A.K. Tyagi, B. Raj, Scr. Mater. 45, 693 (2001)

W.Q. Li, L. Gao, Nanostruct. Mater. 11, 1073 (1999)

H.Z. Wang, L. Gao, L.H. Gui, J.K. Guo, Nanostruct. Mater. 10, 947 (1998)

W. Nakao, M. Ono, S.K. Lee, K. Takahashi, K. Ando, J. Eur. Ceram. Soc. 25, 3649 (2005)

E.W. Wong, P.E. Sheehan, C.M. Liebev, Science 277, 1971 (1999)

E.T. Thostenson, Z.F. Ren, T.W. Chou, Compos. Sci. Technol. 61, 1899 (2001)

R.W. Siegel, S.K. Chang, B.J. Ash, J. Stone, P.M. Ajayan, R.W. Doremus, L.S. Schadler, Scr. Mater. 44, 2061 (2001)

G.D. Zhang, J.D. Kuntz, J.L. Wan, A.K. Mukherjee, Nat. Mater. 2, 38 (2003)

K. Balani, S.B. Rao, Y. Chen, T. Laha, A. Agarwal, J. Nanosci. Nanotechnol. 7, 3553 (2007)

R. Krishnan, S. Dash, C. Babu Rao, R.V. Subba Rao, A.K. Tyagi, B. Raj, Scr. Mater. 45, 693 (2001)

J. Ilavsky, C.C. Berndt, H. Herman, P. Chraska, J. Dubsky, J. Therm. Spray. Technol. 6, 439 (1997)

C.X. Ding, R.A. Zatorski, H. Herman, Thin Solid Films. 118, 467 (1984)

G.N. Heintze, S. Uematsu, Surf. Coat. Technol. 150, 213 (1992)

C. Batista, A. Portinha, P.M. Ribeiro, V. Teixeira, M.F. Costa, C.R. Oliveria, Appl. Surf. Sci. 247, 313 (2005)

S. Ahmaniemi, P. Vuoristo, T. Mantyla, Mater. Sci. Eng. A 366, 175 (2004)

J. Lawrence, L. Li, Surf. Coat. Technol. 162, 94 (2003)

G.M. Pharr, W.C. Oliver, F.R. Brotzen, J. Mater. Res. 7, 613 (1992)

G.R. Anstis, P. Chantikul, B.R. Lawn, D.B. Marshall, J. Am. Ceram. Soc. 64, 533 (1981)

H. Luo, D. Goberman, L. Shaw, M. Gell, Mater. Sci. Eng. A 346, 237 (2003)

F. Tabcret, F. Osterstock, Philos. Mag. 83, 125 (2003)

A.E. Giannakopoulos, S. Suresh, Scr. Mater. 40, 1191 (1999)

T.W. Ebbesen, P.M. Ajayan, Nature 358, 220 (1992)

S. Iijima, T. Ichihashi, Nature 364, 603 (1993)

W.H. Gitzen, Alumina as a Ceramic Material (American Ceramic Society, Westerville, 1970)

Y.P. Lei, H. Murakawa, Y.W. Shi, X.Y. Li, Comput. Mater. Sci. 21, 276 (2001)

C.Y. Cui, T.W. Chou, Phys. Rev. B 71, 075409 (2005)

M.A. Osman, D. Srivastava, Nanotechnology 12, 21 (2001)

S. Berber, Y.K. Kwon, D. Tománek, Phys. Rev. Lett. 84, 4613 (2000)

E.T. Thostenson, T.W. Chou, J. Phys. D 36, 573 (2003)

B. Bhushan, B.K. Gupta, Handbook of Tribology: Materials, Coatings and Surface Treatments (McGraw Hill, New York, 1991)

Y. Mori, J.W. Hopmans, A.P. Mortensen, G.J. Kluitenberg, Vadose Zone J. 2, 561 (2003)

Z. Wang, A. Kulkarni, S. Deshpande, T. Nakamura, H. Herman, Acta Mater. 51, 5319 (2003)

F.P. Incropera, D.P. Dewitt, Fundamentals of Heat and Mass Transfer (Wiley, New York, 2002)

V.K. Tolpygo, D.R. Clarke, Acta Mater. 46, 5153 (1998)

C. Li, T.W. Chou, Phys. Rev. B 71, 235414 (2005)

B.I. Yakobson, P. Avouris, Carbon Nanotube: Synthesis, Structure, Properties, and Applications (Springer, Berlin, 2001)

W.T. Langford, The Making, Shaping and Treating of Steel (The Association of Iron and Steel Engineers, Pennsylvania, 1985)

K. Balani, A. Agarwal, Nanotechnology 19, 165701 (2008)

Y. Chen, K. Balani, A. Agarwal, Appl. Phys. Lett. 91, 031903 (2007)

D.R. Larson, J.A. Coppola, D.P.H. Hasselman, R.C. Bradt, J. Am. Ceram. Soc. 57, 417 (1974)

R.S. Lima, B.R. Marple, Mater. Sci. Eng. A 395, 269 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Y., Samant, A., Balani, K. et al. Effect of laser melting on plasma-sprayed aluminum oxide coatings reinforced with carbon nanotubes. Appl. Phys. A 94, 861–870 (2009). https://doi.org/10.1007/s00339-008-4990-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-008-4990-4