Abstract

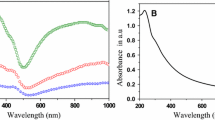

This study presents the eco-friendly composites coating with advanced properties that are prepared by chitosan (CS)-modified graphene oxide (GO) filled acrylic-based coating. Photo-curable acrylic-based nanocomposite containing different amounts of chitosan-modified graphene oxide (CS–GO) and the effect of CS–GO on the coating morphology, UV-curing, transparency, tribological, antimicrobial, thermal and anticorrosion properties was studied. The curing study confirmed that the CS–GO absorbed photon but did not affect the final conversion of the coatings. The results of corrosion analysis demonstrated that the CS–GO filled nanocomposite coatings have higher corrosion protection ability than that of pure acrylic and GO filled coatings. The antimicrobial properties of CS–GO filled coating showed that the antimicrobial performance enhanced as the concentration of CS–GO increased. The optical transmittance study shows that the coating's film transparency decreased with increasing CS–GO concentration, but all of the nanocomposite coatings have a high visible transmittance. This study attributes the enhanced properties to the dispersion of the chitosan-modified GO, which greatly improved the interfacial strength of CS–GO and polymeric matrix and enhanced corrosion properties.

Similar content being viewed by others

References

Ceccia S, Turcato EA, Maffettone PL, Bongiovanni R (2008) Nanocomposite UV-cured coatings: organoclay intercalation by an epoxy resin. Prog Org Coat 63:110–115. https://doi.org/10.1016/j.porgcoat.2008.04.012

Shemper BS, Morizur JF, Alirol M et al (2004) Synthetic clay nanocomposite-based coatings prepared by UV-cure photopolymerization. J Appl Polym Sci 93:1252–1263. https://doi.org/10.1002/app.20580

Decker C, Keller L, Zahouily K, Benfarhi S (2005) Synthesis of nanocomposite polymers by UV-radiation curing. Polymer 46:6640–6648. https://doi.org/10.1016/j.polymer.2005.05.018

Dixit A, Wazarkar K, Sabnis AS (2021) Antimicrobial UV curable wood coatings based on citric acid. Pigment Resin Technol 50:533–544. https://doi.org/10.1108/PRT-07-2020-0067

Uh FM, Davuluri SP, Wong SC, Webster DC (2004) Nanoclay reinforced UV curable high-barrier coatings. Compos Technol 2020:719–724

Belon C, Chemtob A, Croutxé-Barghorn C et al (2010) Nanocomposite coatings via simultaneous organic-inorganic photo-induced polymerization: synthesis, structural investigation and mechanical characterization. Polym Int 59:1175–1186. https://doi.org/10.1002/pi.2846

Xiao C, Zheng K, Chen S et al (2023) Additive manufacturing of high solid content lunar regolith simulant paste based on vat photopolymerization and the effect of water addition on paste retention properties. Addit Manuf 71:103607. https://doi.org/10.1016/j.addma.2023.103607

Sangermano M, Malucelli G, Amerio E et al (2005) Photopolymerization of epoxy coatings containing silica nanoparticles. Prog Org Coat 54:134–138. https://doi.org/10.1016/j.porgcoat.2005.05.004

Amerio E, Sangermano M, Malucelli G et al (2005) Preparation and characterization of hybrid nanocomposite coatings by photopolymerization and sol-gel process. Polymer 46:11241–11246. https://doi.org/10.1016/j.polymer.2005.09.062

Njoku CN, Arukalam IO, Bai W, Li Y (2018) Optimizing maleic anhydride microcapsules size for use in self-healing epoxy-based coatings for corrosion protection of aluminum alloy. Mater Corros 69:1257–1267. https://doi.org/10.1002/maco.201709972

Arukalam IO, Ishidi EY, Obasi HC et al (2020) Exploitation of natural gum exudates as green fillers in self-healing corrosion-resistant epoxy coatings. J Polym Res 27:1. https://doi.org/10.1007/s10965-020-02055-y

Keller L, Decker C, Zahouily K et al (2004) Synthesis of polymer nanocomposites by UV-curing of organoclay-acrylic resins. Polymer 45:7437–7447. https://doi.org/10.1016/j.polymer.2004.08.040

Sangermano M, Amerio E, Priola A et al (2006) Preparation and characterization of acrylic resin/titania hybrid nanocomposite coatings by photopolymerization and sol-gel process. J Appl Polym Sci 102:4659–4664. https://doi.org/10.1002/app.24707

Wang YY, Hsieh TE (2005) Preparation and properties of polyacrylate/clay photocured nanocomposite materials. Chem Mater 17:3331–3337. https://doi.org/10.1021/cm0487268

Uhl FM, Webster DC, Davuluri SP, Wong SC (2006) UV curable epoxy acrylate-clay nanocomposites. Eur Polym J 42:2596–2605. https://doi.org/10.1016/j.eurpolymj.2006.06.016

Cho JD, Kim YB, Ju HT, Hong JW (2005) The effects of silica nanoparticles on the photocuring behaviors of UV-curable polyester acrylate-based coating systems. Macromol Res 13:362–365. https://doi.org/10.1007/BF03218467

Sørensen PA, Kiil S, Dam-Johansen K, Weinell CE (2009) Anticorrosive coatings: a review. J Coat Technol Res 6:135–176. https://doi.org/10.1007/s11998-008-9144-2

Yang F, Liu T, Li J et al (2018) Anticorrosive behavior of a zinc-rich epoxy coating containing sulfonated polyaniline in 3.5% NaCl solution. RSC Adv 8:13237–13247. https://doi.org/10.1039/c8ra00845k

Zhang C, Zhang X, Santosh M et al (2020) Zircon Hf–O–Li isotopes of granitoids from the central Asian orogenic belt: implications for supercontinent evolution. Gondwana Res 83:132–140. https://doi.org/10.1016/j.gr.2020.02.003

Pecora M, Pannier Y, Lafarie-Frenot MC et al (2016) Effect of thermo-oxidation on the failure properties of an epoxy resin. Polym Test 52:209–217. https://doi.org/10.1016/j.polymertesting.2016.04.008

Woo RSC, Chen Y, Zhu H et al (2007) Environmental degradation of epoxy-organoclay nanocomposites due to UV exposure. Part I: photo-degradation. Compos Sci Technol 67:3448–3456. https://doi.org/10.1016/j.compscitech.2007.03.004

Foroutani K, Pourabbas B, Sharif M et al (2014) In situ deposition of polythiophene nanoparticles on flexible transparent films: effect of the process conditions. Mater Sci Semicond Process 19:57–65. https://doi.org/10.1016/j.mssp.2013.11.012

Zhao X, Fan B, Qiao N et al (2024) Stabilized Ti3C2Tx-doped 3D vesicle polypyrrole coating for efficient protection toward copper in artificial seawater. Appl Surf Sci 642:158639. https://doi.org/10.1016/j.apsusc.2023.158639

Wang K, Zhu J, Wang H et al (2022) Air plasma-sprayed high-entropy (Y0.2Yb0.2Lu0.2Eu0.2Er0.2)3Al5O12 coating with high thermal protection performance. J Adv Ceram 11:1571–1582. https://doi.org/10.1007/s40145-022-0630-2

Xie J, Chen Y, Yin L et al (2021) Microstructure and mechanical properties of ultrasonic spot welding TiNi/Ti6Al4V dissimilar materials using pure Al coating. J Manuf Process 64:473–480. https://doi.org/10.1016/j.jmapro.2021.02.009

Cho JD, Ju HT, Hong JW (2005) Photocuring kinetics of UV-initiated free-radical photopolymerizations with and without silica nanoparticles. J Polym Sci Part A Polym Chem 43:658–670. https://doi.org/10.1002/pola.20529

Xu GC, Li AY, De ZL et al (2003) Synthesis and characterization of silica nanocomposite in situ photopolymerization. J Appl Polym Sci 90:837–840. https://doi.org/10.1002/app.12650

Foroutani K, Pourabbas B, Sharif M et al (2014) Preparation of conductive flexible films by in situ deposition of polythiophene nanoparticles on polyethylene naphthalate. Mater Sci Semicond Process 18:6–14. https://doi.org/10.1016/j.mssp.2013.10.015

Chen J, Zhang Z, Lu H (2022) Structure design and properties investigation of Bi2O2Se/graphene van der Waals heterojunction from first-principles study. Surf Interfaces 33:102289. https://doi.org/10.1016/j.surfin.2022.102289

Esmaeili-Faraj SH, Hassanzadeh A, Shakeriankhoo F et al (2021) Diesel fuel desulfurization by alumina/polymer nanocomposite membrane: experimental analysis and modeling by the response surface methodology. Chem Eng Process Process Intensif 164:108396. https://doi.org/10.1016/j.cep.2021.108396

Dhanola A, Bisht AS, Kumar A, Kumar A (2018) Influence of natural fillers on physico-mechanical properties of luffa cylindrica/ polyester composites. Mater Today Proc 5:17021–17029. https://doi.org/10.1016/j.matpr.2018.04.107

Kocaman S, Ahmetli G, Materials A (2016) Eco-friendly natural filler based epoxy composites. Int J Chem Mol Eng 10:471–474

Zhang X, Tang Y, Zhang F, Lee CS (2016) A novel aluminum-graphite dual-ion battery. Adv Energy Mater 6:1502588. https://doi.org/10.1002/aenm.201502588

Huang Z, Luo P, Jia S et al (2022) A sulfur-doped carbon-enhanced Na3V2(PO4)3 nanocomposite for sodium-ion storage. J Phys Chem Solids 167:110746. https://doi.org/10.1016/j.jpcs.2022.110746

Ashassi-Sorkhabi H, Kazempour A (2020) Chitosan, its derivatives and composites with superior potentials for the corrosion protection of steel alloys: a comprehensive review. Carbohydr Polym 237:116110. https://doi.org/10.1016/j.carbpol.2020.116110

John S, Joseph A, Jose AJ, Narayana B (2015) Enhancement of corrosion protection of mild steel by chitosan/ZnO nanoparticle composite membranes. Prog Org Coat 84:28–34. https://doi.org/10.1016/j.porgcoat.2015.02.005

Zheludkevich ML, Tedim J, Freire CSR et al (2011) Self-healing protective coatings with “green” chitosan based pre-layer reservoir of corrosion inhibitor. J Mater Chem 21:4805–4812. https://doi.org/10.1039/c1jm10304k

Selvam V, Kumar MSC, Vadivel M (2013) Mechanical properties of epoxy/chitosan biocomposites. Int J Chem Sci 11:1103–1109

Jabeen S, Saeed S, Kausar A et al (2016) Influence of chitosan and epoxy cross-linking on physical properties of binary blends. Int J Polym Anal Charact 21:163–174. https://doi.org/10.1080/1023666X.2016.1131404

Ahmad B, Ashfaq M, Joy A, Carlos ZASM (2017) Fabrication and characterization of an eco-friendly biodegradable epoxy/chitosan composites. Am J Mater Sci 7:166–169

El-Fattah MA, El Saeed AM, Azzam AM et al (2016) Improvement of corrosion resistance, antimicrobial activity, mechanical and chemical properties of epoxy coating by loading chitosan as a natural renewable resource. Prog Org Coat 101:288–296. https://doi.org/10.1016/j.porgcoat.2016.09.002

Ma IW, Sh A, Ramesh K, Vengadaesvaran B, Ramesh S, Arof AK (2017) Anticorrosion properties of epoxy-nanochitosan nanocomposite coating. Progress Org Coat 113:74–81. https://doi.org/10.1016/j.porgcoat.2017.08.014

Khakpour M, Vaferi B (2023) Experimental and modeling analyses of stability and thermophysical characteristics of graphene oxide, carbon nanotube, and silicon carbide dispersion in propylene glycol. Heat Transf Res 54:1–15. https://doi.org/10.1615/HeatTransRes.2023047129

Rana VK, Choi MC, Kong JY et al (2011) Synthesis and drug-delivery behavior of chitosan-functionalized graphene oxide hybrid nanosheets. Macromol Mater Eng 296:131–140. https://doi.org/10.1002/mame.201000307

Wang Z, Fu W, Hu L et al (2021) Improvement of electron transfer efficiency during denitrification process by Fe-Pd/multi-walled carbon nanotubes: possessed redox characteristics and secreted endogenous electron mediator. Sci Total Environ 781:146686. https://doi.org/10.1016/j.scitotenv.2021.146686

Huang Z, Luo P, Wu Q, Zheng H (2022) Constructing one-dimensional mesoporous carbon nanofibers loaded with NaTi2(PO4)3 nanodots as novel anodes for sodium energy storage. J Phys Chem Solids 161:110479. https://doi.org/10.1016/j.jpcs.2021.110479

Fang M, Wang K, Lu H et al (2009) Covalent polymer functionalization of graphene nanosheets and mechanical properties of composites. J Mater Chem 19:7098–7105. https://doi.org/10.1039/b908220d

Han D, Yan L, Chen W, Li W (2011) Preparation of chitosan/graphene oxide composite film with enhanced mechanical strength in the wet state. Carbohydr Polym 83:653–658. https://doi.org/10.1016/j.carbpol.2010.08.038

Zare M, Sharif M, Kashkooli A (2014) Study on the effect of polypyrrole and polypyrrole/graphene oxide nanoparticles on the microstructure, electrical and tensile properties of polypropylene nanocomposites. Polym Plast Technol Eng 53:1392–1401. https://doi.org/10.1080/03602559.2014.909472

Le TT, Nguyen TV, Nguyen TA et al (2019) Thermal, mechanical and antibacterial properties of water-based acrylic polymer/SiO2–Ag nanocomposite coating. Mater Chem Phys 232:362–366. https://doi.org/10.1016/j.matchemphys.2019.05.001

Nguyen TV, Do TV, Ha MH et al (2020) Crosslinking process, mechanical and antibacterial properties of UV-curable acrylate/Fe3O4-Ag nanocomposite coating. Prog Org Coat 139:105325. https://doi.org/10.1016/j.porgcoat.2019.105325

Shimazaki Y, Miyazaki Y, Takezawa Y et al (2007) Excellent thermal conductivity of transparent cellulose nanofiber/epoxy resin nanocomposites. Biomacromol 8:2976–2978. https://doi.org/10.1021/bm7004998

Iijima T, Miura S, Fukuda W, Tomoi M (1993) Effect of cross-link density on modification of epoxy resins by N-phenylmaleimide-styrene copolymers. Eur Polym J 29:1103–1113

Su Y, Shen Z, Long X et al (2023) Gaussian filtering method of evaluating the elastic/elasto-plastic properties of sintered nanocomposites with quasi-continuous volume distribution. Mater Sci Eng A 872:145001. https://doi.org/10.1016/j.msea.2023.145001

Helander IM, Nurmiaho-Lassila EL, Ahvenainen R et al (2001) Chitosan disrupts the barrier properties of the outer membrane of gram-negative bacteria. Int J Food Microbiol 71:235–244. https://doi.org/10.1016/S0168-1605(01)00609-2

Liu H, Du Y, Wang X, Sun L (2004) Chitosan kills bacteria through cell membrane damage. Int J Food Microbiol 95:147–155. https://doi.org/10.1016/j.ijfoodmicro.2004.01.022

Carlson RP, Taffs R, Davison WM, Stewart PS (2008) Anti-biofilm properties of chitosan-coated surfaces. J Biomater Sci Polym Ed 19:1035–1046. https://doi.org/10.1163/156856208784909372

Zhu S, Zhu J, Ye S et al (2023) High-entropy rare earth titanates with low thermal conductivity designed by lattice distortion. J Am Ceram Soc 106:6279–6291. https://doi.org/10.1111/jace.19233

Acknowledgements

The research for this paper was financially supported by the Islamic Azad University, Shiraz Branch, Iran, through project entitled “Enhancement of properties in epoxy resins using chitosan biopolymer and graphene oxide nanoparticles (No 1630110170003).”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharif, M., Tavakoli, S. Chitosan-modified graphene oxide filled photo-curable nanocomposite coating with advanced properties. Polym. Bull. (2024). https://doi.org/10.1007/s00289-024-05202-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00289-024-05202-3