Abstract

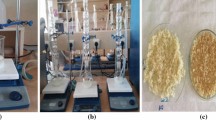

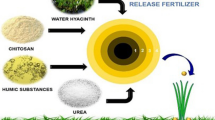

The present study was undertaken with the aim of evaluating the ginger essential oil potential and its urea-loading efficacy in the preparation of control-releasing chitosan microspheres. The ginger oil for hydro-distillation was extracted by applying Clevenger apparatus, chemical composition was characterized by FTIR, and the GC-MS was used to identify the oil compounds. Urea-loaded chitosan microsphere formulations were formulated through modified emulsification and cross-linking procedure. The various factors and levels related to preparation of urea-loaded chitosan microspheres were evaluated using response surface test. The present study was also an effort to observe the yield and content of nitrogen. Additionally, FTIR and SEM were applied to characterize the microspheres. The results show the yield of ginger oil as 6.0%. Main compounds identified by GC-MS were gingerol, decanal, isoshogaol, octanal, and others. FTIR also showed that some typical bands appeared in ginger oil. The nitrogen content % in urea-loaded microspheres showed a significantly higher value in proportion to higher oil volume and cross-linking. However, by decreasing the amount of urea and enhancing acetic acid, nitrogen content was decreased. The lower oil concentrations improved the microsphere surface structure and morphology. Response surface analysis showed that the optimum preparation conditions are as follows: 2.094% of Span 80, 2.302% of acetic acid, and cross-linking agent ratio of formaldehyde to glutaraldehyde 1:8.15. Under these conditions, the theoretical value of nitrogen content of urea-loaded chitosan microspheres was 4.683%. According to release test, the urea diffused uniformly in the microspheres after 48 h. It is concluded that the use of ginger oil in control release of fertilizers is the right option in the formulations of control-releasing micro-fertilizers.

Similar content being viewed by others

References

Antón-Herrero R, García-Delgado C, Mayans B, Camacho-Arévalo R, Eymar E (2020) Impact of new micro carbon technology based fertilizers on growth, nutrient efficiency and root cell morphology of Capsicum annuum L. Agronomy 10:1165

Codur A-M (2021) Agriculture, food, and environment. In: Environmental and natural resource economics, Routledge, pp. 467–500

Hayatsu M (2014) A novel function of controlled-release nitrogen fertilizers. Microbes Environ 29:121–122

Leghari SJ, Wahocho NA, Laghari GM, HafeezLaghari A, MustafaBhabhan G, HussainTalpur K, Bhutto TA, Wahocho SA, Lashari AA (2016) Role of nitrogen for plant growth and development: a review. Adv Environ Biol 10:209–219

Guo H, White JC, Wang Z, Xing B (2018) Nano-enabled fertilizers to control the release and use efficiency of nutrients. Curr Opin Environ Sci Health 6:77–83

Tong X, He X, Duan H, Han L, Huang G (2018) Evaluation of controlled release urea on the dynamics of nitrate, ammonium, and its nitrogen release in black soils of northeast China. Int J Environ Res Public Health 15:119

Rekowski A, Wimmer MA, Hitzmann B, Hermannseder B, Hahn H, Zörb C (2020) Application of urease inhibitor improves protein composition and bread-baking quality of urea fertilized winter wheat. Plant Nutr Soil Sci 183:260–270

Zhang Y, Luo J, Peng F, Xiao Y, Du A (2021) Application of bag-controlled release fertilizer facilitated new root formation, delayed leaf, and root senescence in peach trees and improved nitrogen utilization efficiency. Front Plant Sci 12:565

Zafar N, Niazi MBK, Sher F, Khalid U, Jahan Z, Shah GA, Zia M (2021) Starch and polyvinyl alcohol encapsulated biodegradable nanocomposites for environment friendly slow release of urea fertilizer. Chem Eng J Adv 7:100123

Klein M, Poverenov E (2020) Natural biopolymer-based hydrogels for use in food and agriculture. J Sci Food Agric 100:2337–2347

Basta AH, Lotfy VF, Eldewany C (2021) Comparison of copper-crosslinked carboxymethyl cellulose versus biopolymer-based hydrogels for controlled release of fertilizer. Polym Plast Technol Eng 60:1884–1897

Chen J, Fan X, Zhang L, Chen X, Sun S, Sun RC (2020) Research progress in lignin-based slow/controlled release fertilizer. Chemsuschem 13:4356–4366

Li T, Gao B, Tong Z, Yang Y, Li Y (2019) Chitosan and graphene oxide nanocomposites as coatings for controlled-release fertilizer. Water Air Soil Pollut 230:1–9

Azeem B, KuShaari K, Naqvi M, Kok Keong L, Almesfer MK, Al-Qodah Z, Naqvi SR, Elboughdiri N (2020) Production and characterization of controlled release urea using biopolymer and geopolymer as coating materials. Polymers 12:400

Phang SW, Sin LT, Bee ST, Tee TT (2020) Release kinetic model of nitrogen released encapsulated in starch-alginate controlled released urea: diffusion and its decay release. In: AIP conference proceedings. AIP Publishing LLC, pp. 040006

Tang X, Alavi S (2011) Recent advances in starch, polyvinyl alcohol based polymer blends, nanocomposites and their biodegradability. Carbohydr Polym 85:7–16

Rico-García D, Ruiz-Rubio L, Pérez-Alvarez L, Hernández-Olmos SL, Guerrero-Ramírez GL, Vilas-Vilela JL (2020) Lignin-based hydrogels: synthesis and applications. Polymers 12:81

Faqir Y, Ma J, Chai Y (2021) Chitosan in modern agriculture production. Plant Soil Environ 67:679–699

Ma J, Faqir Y, Tan C, Khaliq G (2022) Terrestrial insects as a promising source of chitosan and recent developments in its application for various industries. Food Chem 373:131407

Varshosaz J (2007) The promise of chitosan microspheres in drug delivery systems. Expert Opin Drug Deliv 4:263–273

Mitra A, Dey B (2011) Chitosan microspheres in novel drug delivery systems. Indian J Pharm Sci 73:355

Hussain MR, Devi RR, Maji TK (2012) Controlled release of urea from chitosan microspheres prepared by emulsification and cross-linking method. Iran Polym J 21:473–479

França D, Medina ÂF, Messa LL, Souza CF, Faez R (2018) Chitosan spray-dried microcapsule and microsphere as fertilizer host for swellable—controlled release materials. Carbohydr Polym 196:47–55

Ofokansi K, Kenechukwu F, Isah A, Okigbo E (2013) Formulation and evaluation of glutaraldehyde-crosslinked chitosan microparticles for the delivery of ibuprofen. Trop J Pharm Res 12:19–25

Manjanna K, Shivakumar B, Kumar TP (2010) Microencapsulation: an acclaimed novel drug-delivery system for NSAIDs in arthritis. Crit Rev Ther Drug Carrier Syst 27:509–545

Ma J, Faqir Y, Chai Y, Wu S, Luo T, Liao S, Kaleri AR, Tan C, Qing Y, Kalhoro MT (2023) Chitosan microspheres-based controlled release nitrogen fertilizers enhance the growth, antioxidant, and metabolite contents of Chinese cabbage. Sci Hortic 308:111542

Qiu X, Tao S, Ren X, Hu S (2012) Modified cellulose films with controlled permeatability and biodegradability by cross-linking with toluene diisocyanate under homogeneous conditions. Carbohydr Polym 88:1272–1280

Campos E, Coimbra P, Gil M (2013) An improved method for preparing glutaraldehyde cross-linked chitosan–poly (vinyl alcohol) microparticles. Polym Bull 70:549–561

Chen C, Gao Z, Qiu X, Hu S (2013) Enhancement of the controlled-release properties of chitosan membranes by cross-linking with suberoyl chloride. Molecules 18:7239–7252

Wang E, Wang X, Wang K, He J, Zhu L, He Y, Chen D, Ouyang P, Geng Y, Huang X (2018) Preparation, characterization and evaluation of the immune effect of alginate/chitosan composite microspheres encapsulating recombinant protein of Streptococcus iniae designed for fish oral vaccination. Fish Shellfish Immunol 73:262–271

Lawrencia D, Wong SK, Low DYS, Goh BH, Goh JK, Ruktanonchai UR, Soottitantawat A, Lee LH, Tang SY (2021) Controlled release fertilizers: a review on coating materials and mechanism of release. Plants 10:238

Zha C, Wang C, Li A (2018) Toxicities of selected essential oils, silicone oils, and paraffin oil against the common bed bug (Hemiptera: Cimicidae). J Econ Entomol 111:170–177

Busdosh M, Atlas R (1977) Toxicity of oil slicks to Arctic amphipods. Arctic 30:85–92

Kalhoro MT, Zhang H, Kalhoro GM, Wang F, Chen T, Faqir Y, Nabi F (2022) Fungicidal properties of ginger (Zingiber officinale) essential oils against Phytophthora colocasiae. Sci Rep 12:1–10

Aafreen MM, Anitha R, Preethi RC, Rajeshkumar S, Lakshmi T (2019) Anti-inflammatory activity of silver nanoparticles prepared from ginger oil—an in vitro approach. Indian J Public Health Res Dev 10:145

Ismanto AW, Kusuma HS, Mahfud M (2018) Solvent-free microwave extraction of essential oil from Melaleuca leucadendra L. In: MATEC web of conferences. EDP Sciences, pp. 03007

Kusuma H, Putri D, Dewi I, Mahfud M (2016) Solvent-free microwave extraction as the useful tool for extraction of edible essential oils. Chem Chem Technol 10:213–218

Kusuma HS, Mahfud M (2015) Box-Behnken design for investigation of microwave-assisted extraction of patchouli oil. In: AIP conference proceedings. AIP Publishing LLC, pp. 050014

Mahfud M, Putri D, Dewi I, Kusuma H (2017) Extraction of essential oil from cananga (Cananga odorata) using solvent-free microwave extraction: a preliminary study. Rasayan J Chem 10:86–91

Kusuma HS, Mahfud M (2018) Kinetic studies on extraction of essential oil from sandalwood (Santalum album) by microwave air-hydrodistillation method. Alex Eng J 57:1163–1172

Matthews KR (2014) Leafy vegetables. In: The produce contamination problem. Elsevier, pp. 187–206

Kusuma HS, Amenaghawon AN, Darmokoesoemo H, Neolaka YA, Widyaningrum BA, Anyalewechi CL, Orukpe PI (2021) Evaluation of extract of Ipomoea batatas leaves as a green coagulant–flocculant for turbid water treatment: Parametric modelling and optimization using response surface methodology and artificial neural networks. Environ Technol Innov 24:102005

Barabadi H, Honary S, Ebrahimi P, Alizadeh A, Naghibi F, Saravanan M (2019) Optimization of myco-synthesized silver nanoparticles by response surface methodology employing Box-Behnken design. Inorg Nano-Met Chem 49:33–43

Ferreira SC, Bruns R, Ferreira HS, Matos GD, David J, Brandão G, da Silva EP, Portugal L, Dos Reis P, Souza A (2007) Box-Behnken design: an alternative for the optimization of analytical methods. Anal Chim Acta 597:179–186

Rigas F, Dritsa V, Marchant R, Papadopoulou K, Avramides E, Hatzianestis I (2005) Biodegradation of lindane by Pleurotus ostreatus via central composite design. Environ Int 31:191–196

Buragohain M, Mahanta C (2008) A novel approach for ANFIS modelling based on full factorial design. Appl Soft Comput 8:609–625

Singh G, Kapoor I, Singh P, de Heluani CS, de Lampasona MP, Catalan CA (2008) Chemistry, antioxidant and antimicrobial investigations on essential oil and oleoresins of Zingiber officinale. Food Chem Toxicol 46:3295–3302

Zhang L, Wang H, Tang X, Lu S, Tan Y, Li Q, Wu J (2022) Characterization of aroma volatiles in xilin fire ginger oils by HS-SPME-GC-MS. Int J Food Prop 25:53–64

Lestari RS, Kustiningsih I, Irawanto D, Bahaudin R, Wardana RL, Muhammad F, Suyuti M, Luthfi M (2021) Preparation of chitosan microspheres as carrier material to controlled release of urea fertilizer. S Afr J Chem Eng 38:70–77

Kirk PL (1950) Kjeldahl method for total nitrogen. Anal Chem 22:354–358

de Barros FRV, Botrel DA, Silva EK, Borges SV, de Oliveira CR, Yoshida MI, de Andrade FJP, de Paula RCM (2016) Cashew gum and inulin: new alternative for ginger essential oil microencapsulation. Carbohydr Polym 153:133–142

Tavares L, Noreña CPZ (2020) Encapsulation of ginger essential oil using complex coacervation method: coacervate formation, rheological property, and physicochemical characterization. Food Bioprocess Technol 13:1405–1420

An K, Zhao D, Wang Z, Wu J, Xu Y, Xiao G (2016) Comparison of different drying methods on Chinese ginger (Zingiber officinale Roscoe): changes in volatiles, chemical profile, antioxidant properties, and microstructure. Food Chem 197:1292–1300

Stappen I, Hoelzl A-S, Randjelovic O, Wanner J (2016) Influence of essential ginger oil on human psychophysiology after inhalation and dermal application. Nat Prod Commun 11:1934578X1601101035

Kamaliroosta Z, Kamaliroosta L, Elhamirad A (2013) Isolation and identification of ginger essential oil. J Food Biosci Technol 3:73–80

Wang L-Y, Ma G-H, Su Z-G (2005) Preparation of uniform sized chitosan microspheres by membrane emulsification technique and application as a carrier of protein drug. J Control Release 106:62–75

Li Y, Wu C, Wu T, Wang L, Chen S, Ding T, Hu Y (2018) Preparation and characterization of citrus essential oils loaded in chitosan microcapsules by using different emulsifiers. J Food Eng 217:108–114

Jarosiewicz A, Tomaszewska M (2003) Controlled-release NPK fertilizer encapsulated by polymeric membranes. J Agric Food Chem 51:413–417

Li S, Zhao S, Hou Y, Chen G, Chen Y, Zhang Z (2020) Polylactic acid (PLA) modified by polyethylene glycol (PEG) for the immobilization of lipase. Appl Biochem Biotechnol 190:982–996

Dutta A (2017) Fourier transform infrared spectroscopy. In: Spectroscopic methods for nanomaterials characterization, pp. 73–93

Vo PT, Nguyen HT, Trinh HT, Nguyen VM, Le A-T, Tran HQ, Nguyen TTT (2021) The nitrogen slow-release fertilizer based on urea incorporating chitosan and poly (vinyl alcohol) blend. Environ Technol Innov 22:101528

Zhou X, Cheng XJ, Liu WF, Li J, Ren LH, Dang QF, Feng C, Chen XG (2013) Optimization and characteristics of preparing chitosan microspheres using response surface methodology. J Appl Polym Sci 127:4433–4439

Sinha V, Singla AK, Wadhawan S, Kaushik R, Kumria R, Bansal K, Dhawan S (2004) Chitosan microspheres as a potential carrier for drugs. Int J Pharm 274:1–33

Nayak UY, Gopal S, Mutalik S, Ranjith AK, Reddy MS, Gupta P, Udupa N (2009) Glutaraldehyde cross-linked chitosan microspheres for controlled delivery of zidovudine. J Microencapsul 26:214–222

Acknowledgements

The authors especially thank Natural Science Foundation of Sichuan, China and Longshan academic talent research supporting program of SWUST support. We would also like to thank the reviewers and editor who provided valuable suggestions for improving this paper.

Funding

This work was supported by Sichuan Science and Technology Program (no. 22NSFSC1471), Longshan Academic Talent Research Supporting Program of SWUST (no. 18LZX561).

Author information

Authors and Affiliations

Contributions

YF and YC contributed to conceptualization, methodology, formal analysis, and writing—original draft preparation; SW, TL, SL, LL, and QZ contributed to experiment; AMJ, MTK, JM, CT, and ARK contributed to review and editing; SC and MA contributed to GC-MS analysis; and JM contributed to supervision. All authors have read and agreed to the version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Faqir, Y., Chai, Y., Jakhar, A.M. et al. Ginger-extracted oil as an alternative for the emulsion to prepare chitosan microspheres for urea controlled-release fertilizer. Polym. Bull. 81, 4863–4891 (2024). https://doi.org/10.1007/s00289-023-04911-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04911-5