Abstract

In this paper, a series of ethylene propylene diene monomer/low density polyethylene (EPDM/LDPE) composites with the shape memory effect (SME) are prepared by polymer blending method. The cross-link structure and crystallization are regulated by the impact of thermodynamic factor and content of peroxide, and the influence on SME is also investigated. The results demonstrate that the interfacial adhesion originates from the good interfacial compatibility and interfacial grafting reaction between the phases, and the cross-linked chemical structure improves interfacial adhesion and forms abundant tiny LDPE crystals, which plays a crucial role in exploring the SME and improving the mechanical performance of EPDM/LDPE composites. A balanced state between the mechanical properties and SME is achieved when dicumyl peroxide content is 1 wt.%; the tensile strength and elongation at break reach 19.2 MPa and 1499%, respectively, while the shape fixation ratio (Rf) and shape recovery ratio (Rr) are ~ 99% and ~ 85%, respectively.

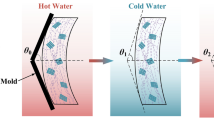

Graphical abstract

Similar content being viewed by others

References

Zende R, Ghase V, Jamdar V (2022) A review on shape memory polymers. Polym-Plast Technol Mater 64(2):467–485

Huang JR, Fan JF, Yin SH, Chen YK (2019) Design of remotely, locally triggered shape-memory materials based on bicontinuous polylactide/epoxidized natural rubber thermoplastic vulcanizates via regulating the distribution of ferroferric oxide. Compos Sci Technol 182:107732

Dayyoub T, Maksimkin AV, Filippova OV, Tcherdyntsev VV, Telyshev DV (2022) Shape memory polymers as smart materials: a review. Polymers-Basel 14(17):3511

Xia Y, He Y, Zhang F, Liu Y, Leng J (2021) A review of shape memory polymers and composites: mechanisms, materials, and applications. Adv Mater 33:2000713

Cui R, Ding J, Chen Y (2019) Magnesium acrylate induced interfacial compatibilization of EPDM/PP thermoplastic vulcanizate and shape memory behavior. Compos A Appl Sci Manuf 122:27–35

Zhang R, Yang Q, Liu M, Chen X, Xue P (2022) Thermal actuation shape memory of ultra-high-molecular-weight polyethylene (UHMWPE) with molecular orientation. Mater Lett 325:132813

Salehi S, Mirjalili G, Amrollahi J (2004) Effects of high-energy electron beam on low-density polyethylene materials containing EVA. J Appl Polym Sci 92:1049–1052

Sun LY, Gao X, Wu DC, Guo QY (2021) Advances in physiologically relevant actuation of shape memory polymers for biomedical applications. Polym Rev 61:280–318

Lendlein A, Langer R (2002) Biodegradable, elastic shape-memory polymers for potential biomedical applications. Science 296:1673–1676

Garle A, Kong S, Ojha U, Budhlall BM (2012) Thermoresponsive semicrystalline poly(epsilon-caprolactone) networks: exploiting cross-linking with cinnamoyl moieties to design polymers with tunable shape memory. Acs Appl Mater Inter 4:645–657

Zhao HX, Lan X, Liu YJ, Bhattacharyya D, Leng JS (2022) Flexural and shape memory properties of unidirectional glass and carbon fibers reinforced hybrid shape memory polymer composites. Smart Mater Struct 31(11):115024

Guo WS, Kang HL, Chen YW, Guo BC, Zhang LQ (2012) Stronger and faster degradable biobased poly(propylene sebacate) as shape memory polymer by incorporating boehmite nanoplatelets. Acs Appl Mater Inter 4:4006–4014

Fan J, Yan M, Huang J, Cao L, Chen Y (2019) Fabrication of smart shape memory fluorosilicon thermoplastic vulcanizates: the effect of interfacial compatibility and tiny crystals. Ind Eng Chem Res 58:15199–15208

Zhao J, Chen M, Wang X, Zhao X, Wang Z, Dang Z, Ma L, Hu G, Chen F (2013) Triple shape memory effects of cross-linked polyethylene/polypropylene blends with cocontinuous architecture. Acs Appl Mater Inter 5:5550–5556

Liu YT, Huang JR, Zhou JD, Wang YP, Cao LM, Chen YK (2020) Influence of selective distribution of SiO2 nanoparticles on shape memory behavior of co-continuous PLA/NR/SiO2 TPVs. Mater Chem Phys 242:122538

Wang YP, Zhang CH, Ren YR, Ding T, Yuan DS, Chen YK (2018) Shape memory properties of dynamically vulcanized poly(lactic acid)/nitrile butadiene rubber (PLA/NBR) thermoplastic vulcanizates: the effect of ACN content in NBR. Polym Advan Technol 29:2336–2343

Jing X, Mi HY, Peng XF, Turng LS (2015) The morphology, properties, and shape memory behavior of polylactic acid/thermoplastic polyurethane blends. Polym Eng Sci 55:70–80

Yan MW, Cao LM, Xu CH, Chen YK (2019) Fabrication of “Zn2+ salt-bondings” cross-linked SBS-g-COOH/ZnO composites: thiol-ene reaction modification of sbs, structure, high modulus, and shape memory properties. Macromolecules 52:4329–4340

Sattar R, Kausar A, Siddiq M (2016) Shape memory and physical properties of composites of polyethylene oxide/poly(propylene glycol)-block-poly(ethylene glycol)-block-poly(propylene glycol)/2,4-toluene diisocyanate, polypyrrole, and modified MWCNT. Polym-Plast Technol Eng 55:1099–1114

Qiu XY, Guo QQ, Wang YY, Huang X, Cao J, Zheng Z, Zhang XX (2020) Self-healing and reconfigurable actuators based on synergistically cross-linked supramolecular elastomer. Acs Appl Mater Inter 12:41981–41990

Marotta A, Lama GC, Ambrogi V, Cerruti P, Giamberini M, Gentile G (2018) Shape memory behavior of liquid-crystalline elastomer/graphene oxide nanocomposites. Compos Sci Technol 159:251–258

Wang GQ, Jiang M, Zhang Q, Wang R, Qu XL, Zhou GY (2018) Biobased multiblock copolymers: synthesis, properties and shape memory behavior of poly(hexamethylene 2,5-furandicarboxylate)-b-poly(ethylene glycol). Polym Degrad Stabil 153:292–297

Wang GQ, Jiang M, Zhang Q, Wang R, Zhou GY (2017) Biobased multiblock copolymers: synthesis, properties and shape memory performance of poly(ethylene 2,5-furandicarboxylate)-b-ly(ethylene glycol). Polym Degrad Stabil 144:121–127

Koosomsuan W, Yamaguchi M, Phinyocheep P, Sirisinha K (2019) High-strain shape memory behavior of PLA-PEG multiblock copolymers and its microstructural origin. J Polym Sci Pol Phys 57:241–256

Wang Y, Pei X, Xia L, Xin Z (2022) Covalent crosslinks turn naturalEucommia ulmoides gum/polybutene-1 composites into multiple shape memory materials. Polym Compos 43:1371–1382

Liu C, Huang JR, Yuan DS, Chen YK (2018) Design of a high-strength XSBR/Fe3O4/ZDMA shape-memory composite with dual responses. Ind Eng Chem Res 57:14527–14534

Chatterjee T, Dey P, Nando GB, Naskar K (2015) Thermo-responsive shape memory polymer blends based on alpha olefin and ethylene propylene diene rubber. Polymer 78:180–192

Xu CH, Wu WC, Zheng ZJ, Wang ZW, Nie JD (2018) Design of shape-memory materials based on sea-island structured EPDM/PP TPVs via in-situ compatibilization of methacrylic acid and excess zinc oxide nanoparticles. Compos Sci Technol 167:431–439

Liu C, Huang J, Yuan D, Chen Y (2018) Design of a high-strength XSBR/Fe3 O4 /ZDMA shape-memory composite with dual responses. Ind Eng Chem Res 57:14527–14534

Khonakdar HA, Jafari SH, Rasouli S, Morshedian J, Abedini H (2007) Investigation and modeling of temperature dependence recovery behavior of shape-memory crosslinked polyethylene. Macromol Theor Simul 16:43–52

Handbook of Polymers. Elsevier Inc., 2022

Chan B, Heng S, Liow SS, Zhang KY, Loh XJ (2017) Dual-responsive hybrid thermoplastic shape memory polyurethane. Mater Chem Front 1:767–779

Xiong J, Huang J, Wang W, Mou W, Chen Y (2021) Study on shape memory behavior of ternary poly(lactic acid)/poly(methyl methacrylate)-grafted natural rubber/natural rubber thermoplastic vulcanizates. Polym-Plast Technol Mater 60:550–561

Xu CH, Huang XH, Li CH, Chen YK, Lin BF, Liang XQ (2016) Design of “Zn2+ salt-bondings” cross-linked carboxylated styrene butadiene rubber with reprocessing and recycling ability via rearrangements of ionic cross-linkings. Acs Sustain Chem Eng 4:6981–6990

Liu W, Ding JP, Chen YK (2022) Thermoplastic vulcanizates dynamically cross-linked by a tailored small molecule. Polym Adv Technol 33:3418–3429

Jiang X, Yuan X, Guo X, Zeng F, Wang H, Liu G (2022) Study on the application of Flory-Huggins interaction parameters in swelling behavior and crosslink density of HNBR/EPDM blend. Fluid Phase Equilibr 563:113589

Narses S, Sadaka F, Brachais C, Couvercelle J (2013) Polymer stain resistance: prediction versus experiment. J Appl Polym Sci 129:2891–2904

Reignier J, Favis BD (2000) Control of the subinclusion microstructure in HDPE/PS/PMMA ternary blends. Macromolecules 33:6998–7008

Radosavljević J, Nikolić L (2018) Interplay between key variables of peroxide cured EPDM and evaluation of electromechanical efficiency for MV cables. J Appl Polym Sci 135:46139

Sasikumar K, Jayesh P, Manoj NR, Mukundan T, Khastgir D (2018) Effect of pristine multiwalled carbon nanotubes on tensile hysteresis in carboxylated nitrile rubber composites. Polym Composite 39:E1269–E1279

Acknowledgements

This work was supported by 2019YFE0110700, the Key Projects of Basic Research and Applied Basic Research in Colleges and Universities in Guangdong Province (Grant Number: 2018KZDXM004) and Special project for innovation of high-end scientific research institutions in Zhongshan City (Grant Number: 2019AG013).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Han, Q., Liu, W., Xu, Y. et al. Fabrication of EPDM/LDPE shape memory composites: the effect of vulcanization and crystals. Polym. Bull. 81, 2179–2196 (2024). https://doi.org/10.1007/s00289-023-04808-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04808-3