Abstract

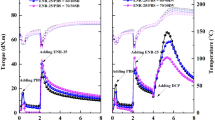

Natural rubber is biopolymer with high mechanical strength and excellent elasticity, but its main drawback is poor thermal stability. Many techniques have been employed to improve its thermo-mechanical properties. In this study, graft copolymerization of styrene, acrylonitrile onto deproteinized natural rubber using tert-butyl hydroperoxide and tetraethylene pentamine as redox initiator and diimide transfer hydrogenation have been investigated. The structural characterization of the obtained products was carried out by Attenuated Total Reflectance Fourier-Transform Infrared Spectroscopy and proton Nuclear Magnetic Resonance. The thermal properties of materials were studied by Thermal Gravimetric Analysis/Differential Thermal Gravimetric Analysis and Differential Scanning Calorimetry. The mechanical properties of the obtained copolymers were confirmed via tensile testing, where the tensile strength of the graft copolymer (DPNR-g-PS.PAN) (3.4 MPa) and hydrogenated-DPNR-g-PS.PAN (H-DPNR-g-PS.PAN) (2.6 MPa), nearly doubled when compared to untreated deproteinized natural rubber (1.5 MPa). The molecular weight distributions of products were determined by Gel Permeation Chromatography, in which the symmetry of molecular weight distribution was improved after each step of the modification.

Similar content being viewed by others

References

Wced SWS (1987) World commission on environment and development. Our common future 1:1–91

Lei H, Lin L, Zhen W, Zhou S, Liu S (2015) Chemocatalytic hydrolysis of cellulose into glucose over solid acid catalysts. Appl Catal B Environ 174–175:225–243. https://doi.org/10.1016/j.apcatb.2015.03.003

Zhang S, Sun J, Zhang X, Xin J, Miao Q, Wang J (2014) Ionic liquid-based green processes for energy production. Chem Soc Rev 22:7838–7869

Benmesli S, Riahi F (2014) Dynamic mechanical and thermal properties of a chemically modified polypropylene/natural rubber thermoplastic elastomer blend. Polym Test 36:54–61. https://doi.org/10.1016/j.polymertesting.2014.03.016

Dung T, Nhan N, Thuong N, Nghia P, Yamamoto Y, Kosugi K, Kawahara S, Thuy T (2016) Modification of Vietnam natural rubber via graft copolymerization with styrene. J Braz Chem Soc. https://doi.org/10.21577/0103-5053.20160217

Kovuttikulrangsie S, Sahakaro K, Intarakong C, Klinpituksa P (2004) PMMA blended and DPNR-g-PMMA coated DPNR and NR-LA for dipping applications. J Appl Polym Sci 2:833–844

Mark HF (2013) Encyclopedia of polymer science and technology, concise. Wiley

Wongthong P, Nakason C, Pan Q, Rempel GL, Kiatkamjornwong S (2013) Modification of deproteinized natural rubber via grafting polymerization with maleic anhydride. Eur Polym J 12:4035–4046

Jiang Y, Wang J, Wu J, Zhang Y (2021) Preparation of high-performance natural rubber/carbon black/molybdenum disulfide composite by using the premixture of epoxidized natural rubber and cysteine-modified molybdenum disulfide. Polym Bull 3:1213–1230

Madhanagopal J, Singh OP, Sornambikai S, Omar AH, Sathasivam KV, Fatihhi SJ, Kadir MRA (2017) Enhanced wide-range monotonic piezoresistivity, reliability of Ketjenblack/deproteinized natural rubber nanocomposite, and its biomedical application: ARTICLE. J Appl Polym Sci. https://doi.org/10.1002/app.44981

Wan L, Deng C, Zhao Z-Y, Chen H, Wang Y-Z (2020) Flame retardation of natural rubber: Strategy and recent progress. Polymers 2:429

Dung TA, Nhan NT, Thuong NT, Nghia PT, Yamamoto Y, Kosugi K, Kawahara S, Thuy TT (2017) Modification of Vietnam natural rubber via graft copolymerization with styrene. J Braz Chem Soc 28:669–675

Saramolee P, Lopattananon N, Sahakaro K (2014) Preparation and some properties of modified natural rubber bearing grafted poly(methyl methacrylate) and epoxide groups. Eur Polym J 56:1–10. https://doi.org/10.1016/j.eurpolymj.2014.04.008

Bhattacharya A, Misra BN (2004) Grafting: a versatile means to modify polymers: techniques, factors and applications. Prog Polym Sci 8:767–814

Choudhary S, Sharma K, Sharma V, Kumar V (2020) Grafting polymers. In: Gutiérrez TJ (ed) Reactive and functional polymers volume two: modification reactions, compatibility and blends. Springer, Cham, pp 199–243. https://doi.org/10.1007/978-3-030-45135-6_8

Kumar D, Pandey J, Raj V, Kumar P (2017) A review on the modification of polysaccharide through graft copolymerization for various potential applications. Open Med Chem J 11(1):109–126. https://doi.org/10.2174/1874104501711010109

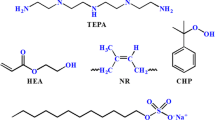

Prasassarakich P, Sintoorahat P, Wongwisetsirikul N (2001) Enhanced graft copolymerization of styrene and acrylonitrile onto natural rubber. J Chem Eng Jpn 2:249–253

Kochthongrasamee T, Prasassarakich P, Kiatkamjornwong S (2006) Effects of redox initiator on graft copolymerization of methyl methacrylate onto natural rubber. J Appl Polym Sci 4:2587–2601

Nakason C, Kaesaman A, Yimwan N (2003) Preparation of graft copolymers from deproteinized and high ammonia concentrated natural rubber latices with methyl methacrylate. J Appl Polym Sci 1:68–75

Nguyen TN, Duy HN, Anh DT, Thi TN, Nguyen TH, Van NN, Quang TT, Huy TN, Thi TT (2020) Improvement of thermal and mechanical properties of Vietnam deproteinized natural rubber via graft copolymerization with methyl methacrylate. Int J Polym Sci 2020:1–11. https://doi.org/10.1155/2020/9037827

Nhan NT, Dung TA, Khanh PD, Thuong NT, Tung NH, Nghia PT, T. T. J. V. J. o. C. Thuy, (2016) Investigation of cure and mechanical properties of deproteined natural rubber-g-poly (methyl methacrylate). Vietnam J Chem 4:520–520

Nakason C, Kaesaman A, Supasanthitikul P (2004) The grafting of maleic anhydride onto natural rubber. Polym Test 1:35–41

Pongsathit S, Pattamaprom C (2018) Irradiation grafting of natural rubber latex with maleic anhydride and its compatibilization of poly(lactic acid)/natural rubber blends. Radiat Phys Chem 144:13–20. https://doi.org/10.1016/j.radphyschem.2017.11.006

Saelao J, Phinyocheep P (2005) Influence of styrene on grafting efficiency of maleic anhydride onto natural rubber. J Appl Polym Sci 1:28–38

Binti Yusof NH (2015) Study on preparation of functional polymer grafted natural rubber. Dissertation, Nagaoka University of Technology

Yusof NH, Kosugi K, Song TK, Kawahara S (2016) Preparation and characterization of poly(stearyl methacrylate) grafted natural rubber in latex stage. Polymer 88:43–51. https://doi.org/10.1016/j.polymer.2016.02.005

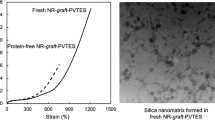

Fukuhara L, Kado N, Thuong NT, Loykulant S, Suchiva K, Kosugi K, Yamamoto Y, Ishii H, Kawahara S (2015) Nanomatrix structure formed by graft copolymerization of styrene onto fresh natural rubber. Rubber Chem Technol 1:117–124

Min LX (2012) Effect of different tackifiers on properties of styrene-grafted natural rubber (snr) and deproteinized natural rubber (DPNR) latex films. Dissertation, University Sains Malaysia

Pukkate N, Kitai T, Yamamoto Y, Kawazura T, Sakdapipanich J, Kawahara S (2007) Nano-matrix structure formed by graft-copolymerization of styrene onto natural rubber. Eur Polym J 8:3208–3214

Rimdusit N, Jubsilp C, Mora P, Hemvichian K, Thuy TT, Karagiannidis P, Rimdusit S (2021) Radiation graft-copolymerization of ultrafine fully vulcanized powdered natural rubber: effects of styrene and acrylonitrile contents on thermal stability. Polymers 19:3447

Suksawad P, Yamamoto Y, Kawahara S (2011) Preparation of thermoplastic elastomer from natural rubber grafted with polystyrene. Eur Polym J 3:330–337

Al-Samhan M, Samuel J, Al-Attar F, Abraham G (2017) Comparative effects of MMT clay modified with two different cationic surfactants on the thermal and rheological properties of polypropylene nanocomposites. Int J Polym Sci 2017:1–8. https://doi.org/10.1155/2017/5717968

Nguyen Duy H, Rimdusit N, Tran Quang T, Phan Minh Q, Vu Trung N, Nguyen TN, Nguyen TH, Rimdusit S, Ougizawa T, Tran Thi T (2021) Improvement of thermal properties of Vietnam deproteinized natural rubber via graft copolymerization with styrene/acrylonitrile and diimide transfer hydrogenation. Polym Adv Technol 2:736–747

Angnanon S, Prasassarakich P, Hinchiranan N (2011) Styrene/acrylonitrile graft natural rubber as compatibilizer in rubber blends. Polym Plast Technol Eng 11:1170–1178

Nallasamy P, Mohan S (2004) Vibrational spectra of cis-1 4-polyisoprene. Arab J Sci Eng part A 1:17–26

Rolere S, Liengprayoon S, Vaysse L, Sainte-Beuve J, Bonfils F (2015) Investigating natural rubber composition with fourier transform infrared (FT-IR) spectroscopy: a rapid and non-destructive method to determine both protein and lipid contents simultaneously. Polymer Test 43:83–93. https://doi.org/10.1016/j.polymertesting.2015.02.011

WhbaSu’aitTian KhoonIbrahimMohamedAhmad RMSLSNSA (2021) Free-radical photopolymerization of acrylonitrile grafted onto epoxidized natural rubber. Polymers 4:660

Alpert NL, Keiser WE, Szymanski HA (1970) The use of characteristic group frequencies in structural analysis. In: Alpert NL, Keiser WE, Szymanski HA (eds) IR. Springer US, Boston, MA, pp 184–302. https://doi.org/10.1007/978-1-4684-8160-0_5

Azhar NHA, Jamaluddin N, Rasid HM, Yusof MJM, Siti Yusoff FM (2015) Studies on hydrogenation of liquid natural rubber using diimide. Int J Polym Sci 2015:1–6. https://doi.org/10.1155/2015/243038

Piya-areetham P, Rempel GL, Prasassarakich P (2014) Hydrogenated nanosized polyisoprene as a thermal and ozone stabilizer for natural rubber blends. Polym Degrad Stab 102:112–121. https://doi.org/10.1016/j.polymdegradstab.2014.01.032

Loadman MJR (1985) The glass transition temperature of natural rubber. J Therm Anal Calorim 4:929–941

Wongthong P, Nakason C, Pan Q, Rempel GL, Kiatkamjornwong S (2014) Styrene-assisted grafting of maleic anhydride onto deproteinized natural rubber. Eur Polym J 59:144–155. https://doi.org/10.1016/j.eurpolymj.2014.07.026

Arayapranee W, Prasassarakich P, Rempel GL (2003) Process variables and their effects on grafting reactions of styrene and methyl methacrylate onto natural rubber. J Appl Polym Sci 1:63–74

Mahittikul A, Prasassarakich P, Rempel GL (2007) Diimide hydrogenation of natural rubber latex. J Appl Polym Sci 3:1188–1199

Ha NT, Kaneda K, Naitoh Y, Fukuhara L, Kosugi K, Kawahara S (2015) Preparation and graft-copolymerization of hydrogenated natural rubber in latex stage. J Appl Polym Sci. https://doi.org/10.1002/app.42435

Mathew AP, Packirisamy S, Thomas S (2001) Studies on the thermal stability of natural rubber/polystyrene interpenetrating polymer networks: thermogravimetric analysis. Polym Degrad Stab 3:423–439

Acknowledgements

This research is funded by the Hanoi University of Science and Technology (HUST) under project number T2018-TĐ-205.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nguyen Thi Ngoc, A., Vu Trung, N., Pham, D.K. et al. Improvement in thermal and mechanical properties of Vietnam deproteinized natural rubber via graft copolymerization with styrene/acrylonitrile and diimide transfer hydrogenation. Polym. Bull. 81, 871–886 (2024). https://doi.org/10.1007/s00289-023-04705-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04705-9