Abstract

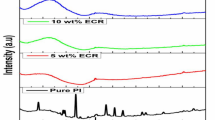

Electrical corrosion resistance (ECR) glass fibers have drawn the attention of the research community owing to their outstanding properties and applicability. Thus, studying its reinforcing influence on the polyimide (PI) matrix remains an important research topic. In this paper, samples of the ECR powder-reinforced PI matrix composites were produced using the spark plasma sintering (SPS) method. The influence of the ECR at different weight concentrations on the crystallinity and microstructure as well as on the mechanical and dielectric properties of the ECR/PI matrix composites was examined using XRD, SEM, nanoindentation tests, and LCR meter. The ECR powder particles were uniformly dispersed into the PI matrix using 3D-turbula mixer, as revealed by SEM images. The mechanical properties of the PI matrix were noticed to be improved by ECR addition. However, in comparison with the pure PI, the ECR/PI matrix composite reinforced with 20 wt% ECR-glass depicted improved hardness by 19.8%, stiffness by 53.8%, and elastic modulus by 64.4 wt%. Furthermore, the ECR/PI matrix composite loaded with 20 wt% ECR showed low dielectric constant and dielectric loss compared to the pure PI sample. In addition, its electrical conductivity was also reduced nearly by 37.3% on exposure to 10 kHz. Finally, the findings suggest the cost-effective means of developing PI composites and their potential for mechanical load-bearing and insulation applications.

Similar content being viewed by others

References

Sathishkumar TP, Satheeshkumar S, Naveen J (2014) Glass fiber-reinforced polymer composites—a review. J Reinf Plast Compos 33:1258–1275

Frederick T, Wallenberger, Watson JC, Hong L (2001) Glass fibers. PPG Industries, Inc, ASM Handbook, vol. 21: Composites

EL-Wazerya MS, EL-Elamya MI, Zoalfakar SH, (2017) Mechanical properties of glass fiber reinforced polyester composites. Int J Appl Sci Eng 14:121–131

Fazle Elahi AHM, Milon Hossain M, Afrin S, Khan MA (2014) Study on the mechanical properties of glass fiber reinforced polyester composites. In: International Conference on Mechanical, Industrial and Energy Engineering 26–27 December, 2014, Khulna, Bangladesh

Patel HS, Vyas HS, Lad BD (1990) Glass-reinforced polyimide composites based on Poly(2,5-furandiylmethylene)—III. High Perform Polym 2:245–249

Landesmanna A, Serutia CA, Batista EM (2015) Mechanical properties of glass fiber reinforced polymers members for structural applications. Mater Res 18:1372–1383

Zaman HU, Khan MA, Khan RA (2011) Physico-mechanical and degradation properties of banana fiber/LDPE composites: effect of acrylic monomer and starch. Compos Interfaces 18:685–700

Li MK, Fan MW, Zhang YF, Liang H, Yang L, Yu TQ, Yang J, Huang J, Fan KJ, Xiong YQ, Qi W, Zuo C, Zhang LG, Liu T (2016) A novel design of insulated core transformer high voltage power supply. In: Proceedings of RuPAC2016, St. Petersburg, Russia, 2016, pp 623–62

Aman A, Abdullah AR, Yaacob MM (2012) Dielectric property of waste tire dust-polypropylene (WTD-PP) composite for high voltage outdoor insulation application. In: IEEE International Power Engineering and Optimization Conference (PEOCO2012). Malaysia: Melaka; 2012, pp 6–7

Ogbonna VE, Popoola API, Popoola OM, Adeosun SO (2022) A review on polyimide reinforced nanocomposites for mechanical, thermal, and electrical insulation application: challenges and recommendations for future improvement. Polym bull 79:663–695

Zhu Z, Yao H, Wang F, Dong J, Wu K, Cao J, Long D (2018) Fiber reinforced polyimide aerogel composites with high mechanical strength for high temperature insulation. Macromol Mater Eng 304:1800676

Naganuma T, Naito K, Kyono J, Kagawa Y (2009) Influence of prepreg conditions on the void occurrence and tensile properties of woven glass fiber-reinforced polyimide composites. Compos Sci Technol 69:2428–2433

Patel HS, Patel HD (1992) Glass-reinforced polyimide composites based on poly(4-furanyl-butan-2-one). High perform Polym 4:35–41

Naito K, Kagawa Y, Utsuno S, Naganuma T, Kurihara K (2009) Dielectric properties of eight-harness-stain fabric glass fiber reinforced polyimide matrix composite in the THz frequency range. NDT&E Int 42:441–445

Fei Z, Yang Z, Chen G, Li K, Zhao S, Su G (2018) Preparation and characterization of glass fiber/polyimide/SiO2 composite aerogels with high specific surface area. J Mater Sci 53:12885–12893

Kudryavtsev MY, Kolesov YI, Mikhailenko NY (2001) Glass fibers and materials made from them, boron free, alkaline free glass fiber for production of fibreglass reinforced plastics. Fibre Chem 33:242–244

Xie J, Yin P, Shi W, Hu M, Wang J, Zhou X, Han J, Cao S, Han L, Yao Y (2016) Corrosion mechanism of e-glass of chemical resistance glass fiber in acid environment. J Wuhan Univer Technol Mater Sci 31:872–876

Sundaram S (2003) Boron-free glass fibres-the trend for the future? Reinf Plast 47:36–40

Yang YF, Qian M (2015) Spark plasma sintering and hot pressing of titanium and titanium alloys. Titanium powder metallurgy. Butterworth-Heinemann, Boston, pp 219–235

Sreeram A, Patel NG, Venkatanarayanan RI, McLaughlin JB, DeLuca SJ, Yuya PA, Krishnan S (2014) Nanomechanical Properties of poly (para-phenylene vinylene) determined using quasi-static and dynamic nanoindentation. Polym Test 37:86–93

Hu W, Du BX, Li J, Liu Y, Liu M (2012) Electrical and mechanical characteristics of polyimide nanocomposite films for wind generator. Confer Paper 2012:1–4. https://doi.org/10.1109/ISGT-Asia.2012.6303179

Koumoulos EP, Jagdale P, Kartsonakis IA, Giorcelli M, Tagliaferro A, Charitidis CA (2015) Carbon nanotube/polymer nanocomposites: a study on mechanical integrity through nanoindentation. Polym Compos 36:1432–1446

Tabor D (1986). In: Blau BJ, Lawn BR (eds) Microindentation techniques in materials science and engineering. ASTM, Philadelphia, p 129

Rowe RC, Roberts RJ (1995) Advances in pharmaceutical sciences. Academic Press, London

Uyor UO, Popoola API, Popoola OM, Aigbodion VS (2022) Thermal, mechanical and dielectric properties of functionalized sandwich BN-BaTiO3-BN/polypropylene nanocomposites. J Alloys Compd 894:162405

Bhushan B (2003) Adhesion and stiction: Mechanisms, measurement techniques, and methods for reduction. J Vac Sci Technol B 21:2262–2296

Park H, Lee SH (2021) Review on interfacial bonding mechanism of functional polymer coating on glass in atomistic modeling perspective. Polymers 13:2244

Zang C, Vehkamaki M, Pietikainen M, Leskela M, Ritala M (2020) Area-selective molecular layer deposition of polyimide on Cu through Cu-catalyzed formation of a crystalline interchain polyimide. Chem Mater 32:5073–5083

Seyedjamali H, Pirisedigh A (2012) Well-dispersed polyimide/TiO2 nanocomposites: in situ sol–gel fabrication and morphological study. Colloid Polym Sci 290:653–659

Joly C, Smaihi M, Porcar L, Noble RD (1999) Polyimide−silica composite materials: How does silica influence their microstructure and gas permeation properties? Chem Mater 11:2331–2338

Landi E, Tampieri A, Celotti G, Sprio S (2000) Densification behaviour and mechanism of synthetic hydroxyapatites. J Eur Ceram Soc 20:2377–2387

Kozak NV (2021) Physical aging of organo-inorganic nanocomposites based on polyimide with card substitutes. Polym J 4:295–303

Schwertz M, Lemonnier S, Barraud E, Carrado A, Vallat M-F, Nardin M (2014) Consolidation by spark plasma sintering of polyimide and polyetheretherketone. J Appl Polym Sci 131:40783

Matizamhuka WR (2016) Spark plasma sintering (SPS) – an advanced sintering technique for structural nanocomposite materials. J South Afr Inst Min Metall 116:1171–1180

Schwertz M, Lemonnier S, Barraud E, Carrado A, Vallat M-F, Nardin M (2015) Spark plasma sintering technology applied to polymer-based composites for structural light weighting. Powd Metall 58:87–90

Kim Y-J, Kim J-H, Ha S-W, Kwon D, Lee J-K (2014) Polyimide nanocomposites with functionalized SiO2 nanoparticles: enhanced processability, thermal and mechanical properties. RSC Adv 4:43371–43377

Ji S, Yang J, Zhao J, Hu Y, Gao H (2018) Study about mechanical property and machinability of polyimide. Polymers 10:173

Wallenberger FT, Watson JC, Li H (2000) Glass fibers. PPG Industries. Inc., ASM International

Viacheslav K (2012) Scanning electron microscopy || synthesis and characterisation of silica/polyamide-imide composite film for enamel wire. https://doi.org/10.5772/1973

Park S (2011) Seo M (2001) Element and processing. In: Park S, Seo M (eds) Interface science and technology. Elsevier, Oxford, pp 431–499

Liu W-D, Zhu B-K, Zhang J, Xu Y-Y (2007) Preparation and dielectric properties of polyimide/silica nanocomposite films prepared from Sol-gel and blending process. Polym Adv Technol 18:522–528

Praveen D, Shashi Kumar ME, Pramod R (2018) Dielectric studies of Graphene and Glass Fiber reinforced composites. IOP Confer. Ser.: Mater. Sci. Eng. 310:012153

Nigrawal A, Chand N (2012) Preparation, dielectric and a.c. conductivity studies on chemically treated sisal powder filled polyvinyl alcohol Biocomposites. Int J Eng Sci Technol 4:191–209

Sabu TJ, Sant KM, Koichi G, Meyyarappallil SS (2012) Polymer composites. Wiley-VCH, Singapore

Didier B, Mercier R, Alberola ND, Bas C (2008) Preparation of polyimide/silica hybrid material by sol-gel process under basic catalysis: Comparison with acid conditions. J Polym Sci Part B: Polym Phys 46:1891–1902

Tommalieh MJ, Zihlif AM, Ragosta G (2011) Electrical and thermal properties of polyimide/silica nanocomposite. J Exp Nanosci 6:652–664

Cho G, Shin M-J, Jeong J-M, Kim J-H, Hong B-H, Koo J-H, Kim Y, Choi E-H (2007) glass tube of high dielectric constant and low dielectric loss for external electrode fluorescent lamps. J Appl Phy 102:113307

Snyder MJ, Mesko MG, Shelby JE (2006) Volatilization of boron from E-glass melts. J Non Cryst Solids 352:669–673

Osterholz FD, Pohl ER (1992) In silanes and other coupling agents. In: Mittal KL (ed) VSP. Utrecht, pp 119–141

Brinker CJ, Scherer GW (1990) In sol-gel science, the physics and chemistry of sol–gel processing. Academic Press, San Diego, pp 97–235

Acknowledgements

The authors wish to thank the Center for Energy and Electric Power, and Center for Surface Engineering Research, Tshwane University of Technology (TUT), South Africa, for their financial support in the course of this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ogbonna, V.E., Popoola, A.P.I., Popoola, O.M. et al. Mechanical and dielectric properties of ECR-glass/polyimide-based composites. Polym. Bull. 80, 11015–11029 (2023). https://doi.org/10.1007/s00289-022-04590-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04590-8