Abstract

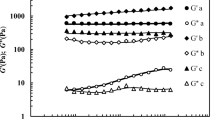

This study aimed to determine the morphological, Rheological, and textural characterization of xanthan gum-salep liposomal gels. The particle size of liposomes (94.21 ± 0.57 nm) was increased in liposomal gels, and it was highest (116.83 ± 1.97 nm) in the K1S3 formulation. The surface charge of liposomes was − 37.40 ± 3.05 mV, and it was significantly decreased by the addition of polymers, changing between − 28.53 and − 30.63 mV. SEM analysis showed that the hydrogel and liposomal gels did not have any aggregation and had a bird net porous morphology and uniform distribution of liposomes. FTIR analysis revealed an interaction between xanthan gum-salep and lecithin. TEM analysis showed spherical structures of liposomes with no obvious aggregation and their size determined by TEM complied with the results taken by DLS analysis. The rheological properties of hydrogels and liposomal gels were characterized by steady shear, frequency, and temperature sweep test, and 3-ITT analysis. All hydrogels and liposomal gels samples showed non-Newtonian, solid-like, and recoverable characters, which increased with an increase in salep concentration in gel formulation. The textural properties of the both hydrogels and liposomal gels were significantly affected by salep-xanthan gum concentration in gels. The results of this study suggested that xanthan gum-salep liposomal gels with strong mechanical properties could be produced by increasing the salep ratio in gel formulation.

Similar content being viewed by others

References

Yang Q, Peng J, Xiao H et al (2022) Polysaccharide hydrogels: functionalization, construction and served as scaffold for tissue engineering. Carbohydr Polym 278:118952. https://doi.org/10.1016/j.carbpol.2021.118952

Qu B, Luo Y (2020) Chitosan-based hydrogel beads: preparations, modifications and applications in food and agriculture sectors – a review. Int J Biol Macromol 152:437–448. https://doi.org/10.1016/j.ijbiomac.2020.02.240

Liu Y, Liang D (2011) Hydrogel integrated with liposome: a two-stage drug delivery system. J Control Release 152(Suppl):e63–e64. https://doi.org/10.1016/j.jconrel.2011.08.124

Liu W, Kong Y, Ye A et al (2020) Preparation, formation mechanism and in vitro dynamic digestion behavior of quercetin-loaded liposomes in hydrogels. Food Hydrocoll 104:105743. https://doi.org/10.1016/j.foodhyd.2020.105743

Wang X, Zhou D, Guo Q, Liu C (2021) Textural and structural properties of a κ-carrageenan–konjac gum mixed gel: effects of κ-carrageenan concentration, mixing ratio, sucrose and Ca2+ concentrations and its application in milk pudding. J Sci Food Agric 101:3021–3029. https://doi.org/10.1002/jsfa.10936

Jiang S, Shang L, Liang H et al (2022) Preparation of konjac glucomannan/xanthan gum/sodium alginatecomposite gel by freezing combining moisture regulation. Food Hydrocoll 127:107499. https://doi.org/10.1016/j.foodhyd.2022.107499

Long J, Etxeberria AE, Nand AV et al (2019) A 3D printed chitosan-pectin hydrogel wound dressing for lidocaine hydrochloride delivery. Mater Sci Eng C 104:109873. https://doi.org/10.1016/j.msec.2019.109873

Ehterami A, Salehi M, Farzamfar S et al (2019) Chitosan/alginate hydrogels containing Alpha-tocopherol for wound healing in rat model. J Drug Deliv Sci Technol 51:204–213. https://doi.org/10.1016/j.jddst.2019.02.032

Acar H, Kurt A (2020) Purified salep glucomannan synergistically interacted with xanthan gum: Rheological and textural studies on a novel pH-/thermo-sensitive hydrogel. Food Hydrocoll 101:105463. https://doi.org/10.1016/j.foodhyd.2019.105463

Bardajee GR, Hooshyar Z (2014) One-pot synthesis of biocompatible superparamagnetic iron oxide nanoparticles/hydrogel based on salep: Characterization and drug delivery. Carbohydr Polym 101:741–751. https://doi.org/10.1016/j.carbpol.2013.10.028

Kaya S, Tekin AR (2001) Effect of salep content on the rheological characteristics of a typical ice-cream mix. J Food Eng 47:59–62. https://doi.org/10.1016/S0260-8774(00)00093-5

Kurt A (2021) Salep glucomannan: properties and applications. Polysaccharides. https://doi.org/10.1002/9781119711414.ch9

Yang X, Shi L, Guo X et al (2016) Convergent in situ assembly of injectable lipogel for enzymatically controlled and targeted delivery of hydrophilic molecules. Carbohydr Polym 154:62–69. https://doi.org/10.1016/j.carbpol.2016.08.028

Khalesi H, Lu W, Nishinari K, Fang Y (2020) New insights into food hydrogels with reinforced mechanical properties: A review on innovative strategies. Adv Colloid Interface Sci 285:102278. https://doi.org/10.1016/j.cis.2020.102278

Dong S, Feng S, Liu F et al (2021) Factors influencing the adhesive behavior of carboxymethyl cellulose-based hydrogel for food applications. Int J Biol Macromol 179:398–406. https://doi.org/10.1016/j.ijbiomac.2021.03.027

Capra P, Musitelli G, Perugini P (2017) Wetting and adhesion evaluation of cosmetic ingredients and products: correlation of in vitro–in vivo contact angle measurements. Int J Cosmet Sci 39:393–401. https://doi.org/10.1111/ics.12388

Serrero A, Trombotto S, Bayon Y et al (2011) Polysaccharide-based adhesive for biomedical applications: correlation between rheological behavior and adhesion. Biomacromol 12:1556–1566. https://doi.org/10.1021/bm101505r

Ramli NA, Ali N, Hamzah S, Yatim NI (2021) Physicochemical characteristics of liposome encapsulation of stingless bees’ propolis. Heliyon 7:e06649. https://doi.org/10.1016/j.heliyon.2021.e06649

Cao D, Zhang X, Akabar MD et al (2019) Liposomal doxorubicin loaded PLGA-PEG-PLGA based thermogel for sustained local drug delivery for the treatment of breast cancer. Artif Cells, Nanomed Biotechnol 47:181–191. https://doi.org/10.1080/21691401.2018.1548470

Ruozi B, Belletti D, Tombesi A et al (2011) AFM, ESEM, TEM, and CLSM in liposomal characterization: a comparative study. Int J Nanomed 6:557–563. https://doi.org/10.2147/ijn.s14615

Mourtas S, Haikou M, Theodoropoulou M et al (2008) The effect of added liposomes on the rheological properties of a hydrogel: a systematic study. J Colloid Interface Sci 317:611–619. https://doi.org/10.1016/j.jcis.2007.09.070

Araújo D, Alves VD, Campos J et al (2016) Assessment of the adhesive properties of the bacterial polysaccharide FucoPol. Int J Biol Macromol 92:383–389. https://doi.org/10.1016/j.ijbiomac.2016.07.035

Ortan A, Parvu CD, Ghica MV et al (2011) Rheological study of a liposomal hydrogel based on carbopol. Rom Biotechnol Lett 16:47–54

Nair R, Roy Choudhury A (2020) Synthesis and rheological characterization of a novel shear thinning levan gellan hydrogel. Int J Biol Macromol 159:922–930. https://doi.org/10.1016/j.ijbiomac.2020.05.119

Kurt A (2018) Modulating hydrogel characteristics of deacetylated salep glucomannan by blending xanthan gum. Airl Spons 19:15

Han X, Huang J, To AKW et al (2020) CEST MRI detectable liposomal hydrogels for multiparametric monitoring in the brain at 3T. Theranostics 10:2215–2228. https://doi.org/10.7150/thno.40146

Toker OS, Karasu S, Yilmaz MT, Karaman S (2015) Three interval thixotropy test (3ITT) in food applications: a novel technique to determine structural regeneration of mayonnaise under different shear conditions. Food Res Int 70:125–133. https://doi.org/10.1016/j.foodres.2015.02.002

D’Elía NL, Rial Silva R, Sartuqui J et al (2020) Development and characterisation of bilayered periosteum-inspired composite membranes based on sodium alginate-hydroxyapatite nanoparticles. J Colloid Interface Sci 572:408–420. https://doi.org/10.1016/j.jcis.2020.03.086

Ramesh S, Kovelakuntla V, Meyer AS (2021) Three-dimensional printing of stimuli-responsive hydrogel with antibacterial activity. Bioprinting 24:e00106. https://doi.org/10.1016/j.bprint.2020.e00106

Cuomo F, Cofelice M, Lopez F (2019) Rheological characterization of hydrogels from alginate-based nanodispersion. Polymers (Basel). https://doi.org/10.3390/polym11020259

Moreira HR, Munarin F, Gentilini R et al (2014) Injectable pectin hydrogels produced by internal gelation: PH dependence of gelling and rheological properties. Carbohydr Polym 103:339–347. https://doi.org/10.1016/j.carbpol.2013.12.057

Koynova R, Caffrey M (1998) Phases and phase transitions of the phosphatidylcholines. Biochim Biophys Acta - Rev Biomembr 1376:91–145. https://doi.org/10.1016/S0304-4157(98)00006-9

Pippa N, Perinelli DR, Pispas S et al (2018) Studying the colloidal behavior of chimeric liposomes by cryo-TEM, micro-differential scanning calorimetry and high-resolution ultrasound spectroscopy. Colloids Surfaces A Physicochem Eng Asp 555:539–547. https://doi.org/10.1016/j.colsurfa.2018.07.025

Ulrich AS (2002) Biophysical aspects of using liposomes as delivery vehicles. Biosci Rep 22:129–150. https://doi.org/10.1023/A:1020178304031

Kaplan M, Tuğcu-Demiröz F, Vural İ, Çelebi N (2018) Development and characterization of gels and liposomes containing ovalbumin for nasal delivery. J Drug Deliv Sci Technol 44:108–117. https://doi.org/10.1016/j.jddst.2017.12.006

Hurler J, Žakelj S, Mravljak J et al (2013) The effect of lipid composition and liposome size on the release properties of liposomes-in-hydrogel. Int J Pharm 456:49–57. https://doi.org/10.1016/j.ijpharm.2013.08.033

Chandra MV, Shamasundar BA (2015) Texture profile analysis and functional properties of gelatin from the skin of three species of fresh water fish. Int J Food Prop 18:572–584. https://doi.org/10.1080/10942912.2013.845787

Aguilar-Zárate M, Macias-Rodriguez BA, Toro-Vazquez JF, Marangoni AG (2019) Engineering rheological properties of edible oleogels with ethylcellulose and lecithin. Carbohydr Polym 205:98–105. https://doi.org/10.1016/j.carbpol.2018.10.032

Cevher E, Taha MAM, Orlu M, Araman A (2008) Evaluation of mechanical and mucoadhesive properties of clomiphene citrate gel formulations containing carbomers and their thiolated derivatives. Drug Deliv 15:57–67. https://doi.org/10.1080/10717540701829234

Xu P, Song J, Dai Z et al (2021) Effect of Ca2+ cross-linking on the properties and structure of lutein-loaded sodium alginate hydrogels. Int J Biol Macromol 193:53–63. https://doi.org/10.1016/j.ijbiomac.2021.10.114

Eren B, Tuncay Tanrıverdi S, Aydın Köse F, Özer Ö (2019) Antioxidant properties evaluation of topical astaxanthin formulations as anti-aging products. J Cosmet Dermatol 18:242–250. https://doi.org/10.1111/jocd.12665

Das D, Pham HTT, Lee S, Noh I (2019) Fabrication of alginate-based stimuli-responsive, non-cytotoxic, terpolymric semi-IPN hydrogel as a carrier for controlled release of bovine albumin serum and 5-amino salicylic acid. Mater Sci Eng C 98:42–53. https://doi.org/10.1016/j.msec.2018.12.127

Rahman MS, Al-Mahrouqi AI (2009) Instrumental texture profile analysis of gelatin gel extracted from grouper skin and commercial (bovine and porcine) gelatin gels. Int J Food Sci Nutr 60:229–242. https://doi.org/10.1080/09637480902984414

Owczarz P, Rył A, Wichłacz Ż (2019) Application of texture profile analysis to investigate the mechanical properties of thermosensitive injectable chitosan hydrogels. Prog Chem Appl Chitin its Deriv 24:151–163. https://doi.org/10.15259/PCACD.24.014

Adrar N, Bahadori F, Ceylan FD et al (2021) Stability evaluation of interdigitated liposomes prepared with a combination of 1,2-distearoyl-sn-glycero-3-phosphocholine and 1,2-dilauroyl-sn-glycero-3-phosphocholine. J Chem Technol Biotechnol 96:2537–2546. https://doi.org/10.1002/jctb.6793

Kuligowski J, Quintás G, Esteve-Turrillas FA et al (2008) On-line gel permeation chromatography-attenuated total reflectance-Fourier transform infrared determination of lecithin and soybean oil in dietary supplements. J Chromatogr A 1185:71–77. https://doi.org/10.1016/j.chroma.2008.01.048

Kurt A, Kahyaoglu T (2017) Purification of glucomannan from salep: part 2. Struct Characteriz Carbohydr Polym 169:406–416. https://doi.org/10.1016/j.carbpol.2017.04.052

Faria S, De Oliveira Petkowicz CL, De Morais SAL et al (2011) Characterization of xanthan gum produced from sugar cane broth. Carbohydr Polym 86:469–476. https://doi.org/10.1016/j.carbpol.2011.04.063

Li P, Li T, Zeng Y et al (2016) Biosynthesis of xanthan gum by Xanthomonas campestris LRELP-1 using kitchen waste as the sole substrate. Carbohydr Polym 151:684–691. https://doi.org/10.1016/j.carbpol.2016.06.017

Tantipolphan R, Rades T, Medlicott NJ (2009) Swelling lecithin: cholesterol implants for the controlled release of proteins. J Liposome Res 19:37–48. https://doi.org/10.1080/08982100802636434

Sarabandi K, Mahoonak AS, Hamishehkar H et al (2019) Protection of casein hydrolysates within nanoliposomes: antioxidant and stability characterization. J Food Eng 251:19–28. https://doi.org/10.1016/j.jfoodeng.2019.02.004

Acemi A, Çobanoğlu Ö, Türker-Kaya S (2019) FTIR-based comparative analysis of glucomannan contents in some tuberous orchids, and effects of pre-processing on glucomannan measurement. J Sci Food Agric 99:3681–3686. https://doi.org/10.1002/jsfa.9596

Acknowledgements

This research was supported by The Scientific and Technological Research Council of Turkey (TUBITAK) and the project number was 120O315.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Saroglu, O., Karadag, A., Cakmak, Z.H.T. et al. The formulation and microstructural, rheological, and textural characterization of salep-xanthan gum-based liposomal gels. Polym. Bull. 80, 9941–9962 (2023). https://doi.org/10.1007/s00289-022-04546-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04546-y