Abstract

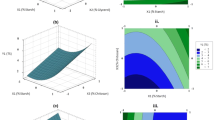

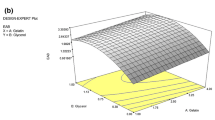

This work is intended to optimize the composition of marine-based biopolymers for desirable packaging material properties. The quantity optimization was sought by empirical response surface methodology. To achieve the goal, Box–Behnken model was applied to the concentration of three independent variables, viz. gelatin (1.0–2.0% w/v), agar (1.0–2.0% w/v) and chitosan (1.0–2.0% w/v). Glycerol was used as a plasticizer and kept constant (25% w/w to total solid mass). The overall desirability function fits with the quadratic model at a 100% level of significance for the optimization of gelatin (1.98% w/v), agar (1.98 w/v) and chitosan (1.94% w/v) to reach minimum water vapor permeability and maximum tensile strength, elongation at break and puncture resistance. The absolute residual error (1.77 to 4.40%) of the experiment and the predicted responses were also validated. The thermal stability (TGA), crystalline structures (XRD), molecular interactions (ATR-FTIR) and topography (AFM) showed that the resultant GAC composite film has a gray color (WI), improved transparency (T) and suitable mechanical strength (WVP, TS, EB and PR) due to existence of hydrogen bonds in uniform granular network and crystallization pattern. The gelatin and agar were supported by chitosan for the reasonably acceptable film properties.

Similar content being viewed by others

References

Global plastic production 1950–2019 | Statista. https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/. Accessed 15 May 2021

Lebreton L, Andrady A (2019) Future scenarios of global plastic waste generation and disposal. Palgrave Commun 5:1–11. https://doi.org/10.1057/s41599-018-0212-7

Pradhan G, Chandra Sharma Y (2020) Studies on green synthesis of glycerol carbonate from waste cooking oil derived glycerol over an economically viable NiMgOx heterogeneous solid base catalyst. J Clean Prod 264:121258. https://doi.org/10.1016/j.jclepro.2020.121258

Neši´c AN, Cabrera-Barjas G, Dimitrijevi´c S, et al (2019) molecules prospect of polysaccharide-based materials as advanced food packaging. https://doi.org/10.3390/molecules25010135

Tharanathan RN (2003) Biodegradable films and composite coatings: past, present and future. Trends Food Sci Technol 14:71–78

Ali E, Sultana S, Hamid SBA et al (2018) Gelatin controversies in food, pharmaceuticals, and personal care products: authentication methods, current status, and future challenges. Crit Rev Food Sci Nutr 58:1495–1511. https://doi.org/10.1080/10408398.2016.1264361

López OV, Zaritzky NE, García MA (2010) Physicochemical characterization of chemically modified corn starches related to rheological behavior, retrogradation and film forming capacity. J Food Eng 100:160–168. https://doi.org/10.1016/j.jfoodeng.2010.03.041

Woggum T, Sirivongpaisal P, Wittaya T (2014) Properties and characteristics of dual-modified rice starch based biodegradable films. Int J Biol Macromol 67:490–502. https://doi.org/10.1016/j.ijbiomac.2014.03.029

do Lago RC, de Oliveira ALM, Cordasso Dias M et al (2020) Obtaining cellulosic nanofibrils from oat straw for biocomposite reinforcement: mechanical and barrier properties. Ind Crops Prod 148:112264. https://doi.org/10.1016/j.indcrop.2020.112264

Li S, Ma Y, Ji T et al (2020) Cassava starch/carboxymethylcellulose edible films embedded with lactic acid bacteria to extend the shelf life of banana. Carbohydr Polym 248:116805. https://doi.org/10.1016/j.carbpol.2020.116805

Mali S, Grossmann MVE, Garcia MA et al (2002) Microstructural characterization of yam starch films. Carbohydr Polym 50:379–386. https://doi.org/10.1016/S0144-8617(02)00058-9

Zavareze EDR, Pinto VZ, Klein B et al (2012) Development of oxidised and heat-moisture treated potato starch film. Food Chem 132:344–350. https://doi.org/10.1016/j.foodchem.2011.10.090

Zareie Z, Tabatabaei Yazdi F, Mortazavi SA (2020) Development and characterization of antioxidant and antimicrobial edible films based on chitosan and gamma-aminobutyric acid-rich fermented soy protein. Carbohydr Polym 244:116491. https://doi.org/10.1016/j.carbpol.2020.116491

Doh H, Dunno KD, Whiteside WS (2020) Cellulose nanocrystal effects on the biodegradability with alginate and crude seaweed extract nanocomposite films. Food Biosci 38:100795. https://doi.org/10.1016/j.fbio.2020.100795

Mohamed SAA, El-Sakhawy M, El-Sakhawy MAM (2020) Polysaccharides, protein and lipid -based natural edible films in food packaging: a review. Carbohydr Polym 238:116178

Park J, Nam J, Yun H et al (2021) Aquatic polymer-based edible films of fish gelatin crosslinked with alginate dialdehyde having enhanced physicochemical properties. Carbohydr Polym 254:117317. https://doi.org/10.1016/j.carbpol.2020.117317

Youssef AM, El-Sayed SM (2018) Bionanocomposites materials for food packaging applications: concepts and future outlook. Carbohydr Polym 193:19–27

Venugopal V (2019) Sulfated and non-sulfated polysaccharides from seaweeds and their uses: an overview. ECronicon Nutr 2:126–141

Rioux LE, Turgeon SL, Beaulieu M (2007) Rheological characterisation of polysaccharides extracted from brown seaweeds. J Sci Food Agric 87:1630–1638. https://doi.org/10.1002/jsfa.2829

Siracusa V, Rocculi P, Romani S, Rosa MD (2008) Biodegradable polymers for food packaging: a review. Trends Food Sci Technol 19:634–643

Chopin N, Guillory X, Weiss P et al (2014) Design polysaccharides of marine origin: chemical modifications to reach advanced versatile compounds. Curr Org Chem 18:867–895. https://doi.org/10.2174/138527281807140515152334

Debeaufort F, Quezada-Gallo JA, Voilley A (1998) Edible films and coatings: tomorrow’s packagings: a review. Crit Rev Food Sci Nutr 38:299–313

Schrieber R, Gareis H (2007) Gelatine handbook: theory and industrial practice. Wiley-VCH

Huang T, Tu Z, Shangguan X et al (2019) Fish gelatin modifications: a comprehensive review. Trends Food Sci Technol 86:260–269

Li P, Wu G (2018) Roles of dietary glycine, proline, and hydroxyproline in collagen synthesis and animal growth. Amino Acids 50:29–38

Djagny KB, Wang Z, Xu S (2001) Gelatin: a valuable protein for food and pharmaceutical industries: review. Crit Rev Food Sci Nutr 41:481–492

Hoque MS, Benjakul S, Prodpran T, Songtipya P (2011) Properties of blend film based on cuttlefish (Sepia pharaonis) skin gelatin and mungbean protein isolate. Int J Biol Macromol 49:663–673. https://doi.org/10.1016/j.ijbiomac.2011.06.028

Derkach SR, Voron’ko NG, Kuchina YA, Kolotova DS (2020) Modified fish gelatin as an alternative to mammalian gelatin in modern food technologies. Polymers (Basel) 12:1–10. https://doi.org/10.3390/polym12123051

Voron’ko NG, Derkach SR, Vovk MA, Tolstoy PM (2017) Complexation of κ-carrageenan with gelatin in the aqueous phase analysed by 1H NMR kinetics and relaxation. Carbohydr Polym 169:117–126. https://doi.org/10.1016/j.carbpol.2017.04.010

Martínez-Sanz M, Gómez-Mascaraque LG, Ballester AR et al (2019) Production of unpurified agar-based extracts from red seaweed Gelidium sesquipedale by means of simplified extraction protocols. Algal Res 38:101420. https://doi.org/10.1016/j.algal.2019.101420

Armisén R, Galatas F (2009) Agar. In: Handbook of hydrocolloids: second edition. Elsevier Inc, pp 82–107

Nieto MB, Akins M (2010) Hydrocolloids in bakery fillings. Hydrocoll food Process 67–107

Mostafavi FS, Zaeim D (2020) Agar-based edible films for food packaging applications: a review. Int J Biol Macromol 159:1165–1176

Rahim A, Marine Polysaccharides Food Applications.pdf

Arvizu-Higuera DL, Rodríguez-Montesinos YE, Murillo-Álvarez JI, et al (2009) Effect of alkali treatment time and extraction time on agar from Gracilaria vermiculophylla. In: Nineteenth international seaweed symposium. Springer, Netherlands, pp 65–69

Jayakumar R, Nwe N, Tokura S, Tamura H (2007) Sulfated chitin and chitosan as novel biomaterials. Int J Biol Macromol 40:175–181

Jiang X, Zhang X (2017) Preparation and properties of plasticized chitosan/starch cast films using AlCl3·6H2O aqueous solution as the solvent. Polym Bull 74:1817–1830. https://doi.org/10.1007/s00289-016-1806-0

Srinivasa PC, Ramesh MN, Tharanathan RN (2007) Effect of plasticizers and fatty acids on mechanical and permeability characteristics of chitosan films. Food Hydrocoll 21:1113–1122. https://doi.org/10.1016/j.foodhyd.2006.08.005

Wang H, Qian J, Ding F (2018) Emerging Chitosan-based films for food packaging applications. J Agric Food Chem 66:395–413

Salomatina EV, Lednev IR, Silina NE et al (2020) Biocompatible compositions based on chitosan and copolymer (lactide–titanium oxide) for engineering of tissue substitutes for wound healing. Polym Bull 77:5083–5101. https://doi.org/10.1007/s00289-019-03007-3

Sobral PJA, Menegalli FC, Hubinger MD, Roques MA (2001) Mechanical, water vapor barrier and thermal properties of gelatin based edible films. Food Hydrocoll 15:423–432. https://doi.org/10.1016/S0268-005X(01)00061-3

Lee M-S, Lee S-H, Ma Y-H et al (2005) Effect of plasticizer and cross-linking agent on the physical properties of protein films. Prev Nutr Food Sci 10:88–91. https://doi.org/10.3746/jfn.2005.10.1.088

Han JH, Aristippos G (2005) Edible films and coatings: a review. In: Innovations in food packaging. Elsevier Ltd, pp 239–262

Maran JP, Sivakumar V, Sridhar R, Thirugnanasambandham K (2013) Development of model for barrier and optical properties of tapioca starch based edible films. Carbohydr Polym 92:1335–1347. https://doi.org/10.1016/j.carbpol.2012.09.069

Muñoz LA, Aguilera JM, Rodriguez-Turienzo L et al (2012) Characterization and microstructure of films made from mucilage of Salvia hispanica and whey protein concentrate. J Food Eng 111:511–518. https://doi.org/10.1016/j.jfoodeng.2012.02.031

Nouraddini M, Esmaiili M, Mohtarami F (2018) Development and characterization of edible films based on eggplant flour and corn starch. Int J Biol Macromol 120:1639–1645. https://doi.org/10.1016/j.ijbiomac.2018.09.126

Ramu Ganesan A, Shanmugam M, Bhat R (2018) Producing novel edible films from semi refined carrageenan (SRC) and ulvan polysaccharides for potential food applications. Int J Biol Macromol 112:1164–1170. https://doi.org/10.1016/j.ijbiomac.2018.02.089

Thakur R, Saberi B, Pristijono P et al (2017) Use of response surface methodology (RSM) to optimize pea starch–chitosan novel edible film formulation. J Food Sci Technol 54:2270–2278. https://doi.org/10.1007/s13197-017-2664-y

Thakur R, Saberi B, Pristijono P et al (2016) Characterization of rice starch-ι-carrageenan biodegradable edible film: effect of stearic acid on the film properties. Int J Biol Macromol 93:952–960. https://doi.org/10.1016/j.ijbiomac.2016.09.053

Nouri L, Mohammadi Nafchi A (2014) Antibacterial, mechanical, and barrier properties of sago starch film incorporated with betel leaves extract. Int J Biol Macromol 66:254–259. https://doi.org/10.1016/j.ijbiomac.2014.02.044

Jasenská D, Kašpárková V, Radaszkiewicz KA et al (2021) Conducting composite films based on chitosan or sodium hyaluronate: properties and cytocompatibility with human induced pluripotent stem cells. Carbohydr Polym 253:117244. https://doi.org/10.1016/j.carbpol.2020.117244

Ba H, Sutter C, Papaefthimiou V et al (2020) Foldable flexible electronics based on few-layer graphene coated on paper composites. Carbon N Y 167:169–180. https://doi.org/10.1016/j.carbon.2020.05.012

Said NS, Sarbon NM (2020) Response surface methodology (RSM) of chicken skin gelatin based composite films with rice starch and curcumin incorporation. Polym Test 81:106161. https://doi.org/10.1016/j.polymertesting.2019.106161

Sandhu KS, Sharma L, Kaur M, Kaur R (2020) Physical, structural and thermal properties of composite edible films prepared from pearl millet starch and carrageenan gum: process optimization using response surface methodology. Int J Biol Macromol 143:704–713. https://doi.org/10.1016/j.ijbiomac.2019.09.111

Singh TP, Chatli MK, Sahoo J (2015) Development of chitosan based edible films: process optimization using response surface methodology. J Food Sci Technol 52:2530–2543. https://doi.org/10.1007/s13197-014-1318-6

Razi ZM, Islam MR, Parimalam M (2019) Mechanical, structural, thermal and morphological properties of a protein (fish scale)-based bisphenol: a composites. Polym Test 74:7–13. https://doi.org/10.1016/j.polymertesting.2018.12.008

Sae-Leaw T, Benjakul S (2015) Physico-chemical properties and fishy odour of gelatin from seabass (Lates calcarifer) skin stored in ice. Food Biosci 10:59–68. https://doi.org/10.1016/j.fbio.2015.02.002

Thiex N (2009) Evaluation of analytical methods for the determination of moisture, crude protein, crude fat, and crude fiber in distillers dried grains with solubles. J AOAC Int 92:61–73. https://doi.org/10.1093/jaoac/92.1.61

Blanco-Pascual N, Montero MP, Gómez-Guillén MC (2014) Antioxidant film development from unrefined extracts of brown seaweeds Laminaria digitata and Ascophyllum nodosum. Food Hydrocoll 37:100–110. https://doi.org/10.1016/j.foodhyd.2013.10.021

Bajić M, Jalšovec H, Travan A et al (2019) Chitosan-based films with incorporated supercritical CO2 hop extract: structural, physicochemical, and antibacterial properties. Carbohydr Polym 219:261–268. https://doi.org/10.1016/j.carbpol.2019.05.003

Doh H, Dunno KD, Whiteside WS (2020) Preparation of novel seaweed nanocomposite film from brown seaweeds Laminaria japonica and Sargassum natans. Food Hydrocoll 105:105744. https://doi.org/10.1016/j.foodhyd.2020.105744

Farhan A, Hani NM (2020) Active edible films based on semi-refined κ-carrageenan: antioxidant and color properties and application in chicken breast packaging. Food Packag Shelf Life 24:100476. https://doi.org/10.1016/j.fpsl.2020.100476

Han JH, Floros JD (1997) Casting antimicrobial packaging films and measuring their physical properties and antimicrobial activity. J Plast Film Sheeting 13:287–298. https://doi.org/10.1177/875608799701300405

Meher JG, Tarai M, Yadav NP et al (2013) Development and characterization of cellulose-polymethacrylate mucoadhesive film for buccal delivery of carvedilol. Carbohydr Polym 96:172–180. https://doi.org/10.1016/j.carbpol.2013.03.076

ASTM E96/E96M—13 Standard test method for water vapor transmission of materials (PDF Download). https://shop.iccsafe.org/astm-e96-e96m-13-standard-test-method-for-water-vapor-transmission-of-materials-pdf-download.html. Accessed 16 May 2021

ASTM D882 - 18 Standard test method for tensile properties of thin plastic sheeting. https://www.astm.org/Standards/D882. Accessed 16 May 2021

Iwata KI, Ishizaki SH, Handa AK, Tanaka MU (2000) Preparation and characterization of edible films from fish water-soluble proteins. Fish Sci 66:372–378. https://doi.org/10.1046/j.1444-2906.2000.00057.x

Ahmad M, Benjakul S (2011) Characteristics of gelatin from the skin of unicorn leatherjacket (Aluterus monoceros) as influenced by acid pretreatment and extraction time. Food Hydrocoll 25:381–388. https://doi.org/10.1016/j.foodhyd.2010.07.004

Nuthong P, Benjakul S, Prodpran T (2009) Characterization of porcine plasma protein-based films as affected by pretreatment and cross-linking agents. Int J Biol Macromol 44:143–148. https://doi.org/10.1016/j.ijbiomac.2008.11.006

Raghav D, Deepthi PR, Dhivyalakshmi R, et al (2017) Investigation on the growth and characterization of pure and oregano extract doped kip single crystals. SJ Impact Factor 6 887. https://doi.org/10.22214/ijraset.2017.11139

Van der Meeren L, Verduijn J, Krysko D V., Skirtach AG (2020) AFM analysis enables differentiation between apoptosis, necroptosis, and Ferroptosis in Murine Cancer Cells. iScience 23:101816. https://doi.org/10.1016/j.isci.2020.101816

Maktoof AA, Elherarlla RJ, Ethaib S (2020) Identifying the nutritional composition of fish waste, bones, scales, and fins. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/871/1/012013

Jakhar JK, Kumar A, Vardia HK (2016) Extraction of gelatin from skin and scale of Indian major carps. Environ Ecol 34:1513–1518

Das MP, Suguna PR, Prasad K et al (2017) Extraction and characterization of gelatin: a functional biopolymer. Int J Pharm Pharm Sci 9:239. https://doi.org/10.22159/ijpps.2017v9i9.17618

Gómez-Guillén MC, Turnay J, Fernández-Díaz MD et al (2002) Structural and physical properties of gelatin extracted from different marine species: a comparative study. Food Hydrocoll 16:25–34. https://doi.org/10.1016/S0268-005X(01)00035-2

Yoshimura K, Terashima M, Hozan D, Shirai K (2000) Preparation and dynamic viscoelasticity characterization of alkali- solubilized collagen from shark skin. J Agric Food Chem 48:685–690. https://doi.org/10.1021/jf990389d

Aguirre-Loredo RY, Rodríguez-Hernández AI, Morales-Sánchez E et al (2016) Effect of equilibrium moisture content on barrier, mechanical and thermal properties of chitosan films. Food Chem 196:560–566. https://doi.org/10.1016/j.foodchem.2015.09.065

Rangel-Marrón M, Montalvo-Paquini C, Palou E, López-Malo A, Optimization of the moisture content, thickness, water solubility and water vapor permeability of sodium alginate edible films

Bajić M, Oberlintner A, Kõrge K et al (2020) Formulation of active food packaging by design: linking composition of the film-forming solution to properties of the chitosan-based film by response surface methodology (RSM) modelling. Int J Biol Macromol 160:971–978. https://doi.org/10.1016/j.ijbiomac.2020.05.186

Ahmadi R, Kalbasi-Ashtari A, Oromiehie A et al (2012) Development and characterization of a novel biodegradable edible film obtained from psyllium seed (Plantago ovata Forsk). J Food Eng 109:745–751. https://doi.org/10.1016/j.jfoodeng.2011.11.010

Ma X, Qiao C, Wang X et al (2019) Structural characterization and properties of polyols plasticized chitosan films. Int J Biol Macromol 135:240–245. https://doi.org/10.1016/j.ijbiomac.2019.05.158

Nordin N, Othman SH, Rashid SA, Basha RK (2020) Effects of glycerol and thymol on physical, mechanical, and thermal properties of corn starch films. Food Hydrocoll 106:105884. https://doi.org/10.1016/j.foodhyd.2020.105884

Alvarado S, Sandoval G, Palos I et al (2015) The effect of relative humidity on tensile strength and water vapor permeability in chitosan, fish gelatin and transglutaminase edible films. Food Sci Technol 35:690–695. https://doi.org/10.1590/1678-457X.6797

Galus S, Lenart A (2013) Development and characterization of composite edible films based on sodium alginate and pectin. J Food Eng 115:459–465. https://doi.org/10.1016/j.jfoodeng.2012.03.006

García MA, Pinotti A, Martino MN, Zaritzky NE (2009) Characterization of starch and composite edible films and coatings. In: Edible films and coatings for food applications. Springer, New York, pp 169–209

Mulyani TS, Egha Rodhu Hansyah Jurusan Teknologi Pangan -FTI -UPN dan, Rungkut Madya -Surabaya J (2010) Sifat fisik dan mekanis edible film dari tepung porang (Amorphopallus oncophyllus) dan karboksimetilselulosa Physical and Mechanical Properties of Edible Film from Porang (Amorphopallus oncophyllus) Flour and Carboxymethylcellulose

Arham R, Mulyati MT, Metusalach M, Salengke S (2016) Physical and mechanical properties of agar based edible film with glycerol plasticizer

Pereda M, Ponce AG, Marcovich NE et al (2011) Chitosan-gelatin composites and bi-layer films with potential antimicrobial activity. Food Hydrocoll 25:1372–1381. https://doi.org/10.1016/j.foodhyd.2011.01.001

Schauer CL, Chen MS, Chatterley M et al (2003) Color changes in chitosan and poly(allyl amine) films upon metal binding. Thin Solid Films 434:250–257. https://doi.org/10.1016/S0040-6090(03)00055-5

Chen CH, Kuo WS, Lai LS (2010) Water barrier and physical properties of starch/decolorized hsian-tsao leaf gum films: impact of surfactant lamination. Food Hydrocoll 24:200–207. https://doi.org/10.1016/j.foodhyd.2009.09.006

Nagarajan M, Benjakul S, Prodpran T, Songtipya P (2014) Properties of bio-nanocomposite films from Tilapia Skin Gelatin as affected by different nanoclays and homogenising conditions. Food Bioprocess Technol 7:3269–3281. https://doi.org/10.1007/s11947-014-1319-5

Sukhija S, Singh S, Riar CS (2016) Analyzing the effect of whey protein concentrate and psyllium husk on various characteristics of biodegradable film from lotus (Nelumbo nucifera) rhizome starch. Food Hydrocoll 60:128–137. https://doi.org/10.1016/j.foodhyd.2016.03.023

Cai L, Shi H, Cao A, Jia J (2019) Characterization of gelatin/chitosan ploymer films integrated with docosahexaenoic acids fabricated by different methods. Sci Rep 9:1–11. https://doi.org/10.1038/s41598-019-44807-x

Liu D, Zhang L (2006) Structure and properties of soy protein plastics plasticized with acetamide. Macromol Mater Eng 291:820–828. https://doi.org/10.1002/mame.200600098

Saarai A, Sedlacek T, Kasparkova V et al (2012) On the characterization of sodium alginate/gelatine-based hydrogels for wound dressing. J Appl Polym Sci 126:E79–E88. https://doi.org/10.1002/app.36590

Soe MT, Chitropas P, Pongjanyakul T et al (2020) Thai glutinous rice starch modified by ball milling and its application as a mucoadhesive polymer. Carbohydr Polym 232:115812. https://doi.org/10.1016/j.carbpol.2019.115812

Zheng XF, Lian Q, LianSong ST (2013) Chitosan-gelatin-pectin composite films from polyion-complex hydrogels. Asian J Chem 25:5363–5366. https://doi.org/10.14233/ajchem.2013.14193

Zhou YC, Xu BH, Yu AB, Zulli P (2002) An experimental and numerical study of the angle of repose of coarse spheres. Powder Technol 125:45–54. https://doi.org/10.1016/S0032-5910(01)00520-4

Nafee NA, Ismail FA, Boraie NA, Mortada LM (2004) Mucoadhesive delivery systems. I. Evaluation of mucoadhesive polymers for buccal tablet formulation. Drug Dev Ind Pharm 30:985–993. https://doi.org/10.1081/DDC-200037245

Shaikh M, Haider S, Ali TM, Hasnain A (2019) Physical, thermal, mechanical and barrier properties of pearl millet starch films as affected by levels of acetylation and hydroxypropylation. Int J Biol Macromol 124:209–219. https://doi.org/10.1016/j.ijbiomac.2018.11.135

Bastarrachea L, Dhawan S, Sablani SS (2011) Engineering properties of polymeric-based antimicrobial films for food packaging. Food Eng Rev 3:79–93. https://doi.org/10.1007/s12393-011-9034-8

Gennadios A, Weller CL, Gooding CH (1994) Measurement errors in water vapor permeability of highly permeable, hydrophilic edible films. J Food Eng 21:395–409. https://doi.org/10.1016/0260-8774(94)90062-0

Rivero S, García MA, Pinotti A (2010) Correlations between structural, barrier, thermal and mechanical properties of plasticized gelatin films. Innov Food Sci Emerg Technol 11:369–375. https://doi.org/10.1016/j.ifset.2009.07.005

Sifuentes-Nieves I, Rendón-Villalobos R, Jiménez-Aparicio A et al (2015) Structural characterization of films based on gelatin/glycerol and carbon nanotubes. Res Artic Phys Physicochem. https://doi.org/10.1155/2015/763931

Saedi S, Shokri M, Rhim JW (2020) Preparation of carrageenan-based nanocomposite films incorporated with functionalized halloysite using AgNP and sodium dodecyl sulfate. Food Hydrocoll 106:105934. https://doi.org/10.1016/j.foodhyd.2020.105934

Sani IK, Pirsa S, Tağı Ş (2019) Preparation of chitosan/zinc oxide/Melissa officinalis essential oil nano-composite film and evaluation of physical, mechanical and antimicrobial properties by response surface method. Polym Test 79:106004. https://doi.org/10.1016/j.polymertesting.2019.106004

Petersen K, Væggemose Nielsen P, Bertelsen G et al (1999) Potential of biobased materials for food packaging. Trends Food Sci Technol 10:52–68

de Lima Barizão C, Crepaldi MI, Oscar de Oliveira S, de Oliveira AC, et al (2020) Biodegradable films based on commercial κ-carrageenan and cassava starch to achieve low production costs. Int J Biol Macromol 165:582–590. https://doi.org/10.1016/j.ijbiomac.2020.09.150

Roy S, Rhim JW (2019) Carrageenan-based antimicrobial bionanocomposite films incorporated with ZnO nanoparticles stabilized by melanin. Food Hydrocoll 90:500–507. https://doi.org/10.1016/j.foodhyd.2018.12.056

Kowalczyk D, Baraniak B (2014) Effect of candelilla wax on functional properties of biopolymer emulsion films: a comparative study. Food Hydrocoll 41:195–209. https://doi.org/10.1016/j.foodhyd.2014.04.004

Mohammed Manshor N, Rezali MI, Jai J, Yahya A (2018) Effect of plasticizers on physicochemical and mechanical properties of chitosan-gelatin films. In: IOP conference series: materials science and engineering. Institute of Physics Publishing, p 012040

Mir SA, Dar BN, Wani AA, Shah MA (2018) Effect of plant extracts on the techno-functional properties of biodegradable packaging films. Trends Food Sci Technol 80:141–154. https://doi.org/10.1016/j.tifs.2018.08.004

Jiang Y, Lan W, Sameen DE et al (2020) Preparation and characterization of grass carp collagen-chitosan-lemon essential oil composite films for application as food packaging. Int J Biol Macromol 160:340–351. https://doi.org/10.1016/j.ijbiomac.2020.05.202

Shahbazi Y (2017) The properties of chitosan and gelatin films incorporated with ethanolic red grape seed extract and Ziziphora clinopodioides essential oil as biodegradable materials for active food packaging. Int J Biol Macromol 99:746–753. https://doi.org/10.1016/j.ijbiomac.2017.03.065

Sivarooban T, Hettiarachchy NS, Johnson MG (2008) Physical and antimicrobial properties of grape seed extract, nisin, and EDTA incorporated soy protein edible films. Food Res Int 41:781–785. https://doi.org/10.1016/j.foodres.2008.04.007

Mathlouthi N, Lallès JP, Lepercq P et al (2002) Xylanase and β-glucanase supplementation improve conjugated bile acid fraction in intestinal contents and increase villus size of small intestine wall in broiler chickens fed a rye-based diet. J Anim Sci 80:2773–2779. https://doi.org/10.2527/2002.80112773x

Sekkal M, Legrand P (1993) A spectroscopic investigation of the carrageenans and agar in the 1500–100 cm−1 spectral range. Spectrochim Acta Part A Mol Spectrosc 49:209–221. https://doi.org/10.1016/0584-8539(93)80176-B

Sonawane RO, Patil SD (2018) Fabrication and statistical optimization of starch-κ-carrageenan cross-linked hydrogel composite for extended release pellets of zaltoprofen. Int J Biol Macromol 120:2324–2334. https://doi.org/10.1016/j.ijbiomac.2018.08.177

Tako M, Higa M, Medoruma K, Nakasone Y (1999) A highly methylated agar from red seaweed, gracttaria arcuata. Bot Mar 42:513–517. doi:https://doi.org/10.1515/bot.1999.058

El-Hefian EA, Nasef MM, Yahaya AH (2012) Preparation and characterization of chitosan/agar blended films: Part 1. chemical structure and morphology. E-J Chem 9:1431–1439. https://doi.org/10.1155/2012/781206

Wu J, Zhong F, Li Y et al (2013) Preparation and characterization of pullulan-chitosan and pullulan-carboxymethyl chitosan blended films. Food Hydrocoll 30:82–91. https://doi.org/10.1016/j.foodhyd.2012.04.002

Wang K, Wang W, Ye R et al (2017) Mechanical and barrier properties of maize starch–gelatin composite films: effects of amylose content. J Sci Food Agric 97:3613–3622. https://doi.org/10.1002/jsfa.8220

Liu L, Cai R, Wang Y et al (2018) Polydopamine-assisted silver nanoparticle self-assembly on sericin/agar film for potential wound dressing application. Int J Mol Sci 19:2875. https://doi.org/10.3390/ijms19102875

Cui L, Gao S, Song X et al (2018) Preparation and characterization of chitosan membranes. RSC Adv 8:28433–28439. https://doi.org/10.1039/c8ra05526b

Rhim JW, Wang LF (2014) Preparation and characterization of carrageenan-based nanocomposite films reinforced with clay mineral and silver nanoparticles. Appl Clay Sci 97–98:174–181. https://doi.org/10.1016/j.clay.2014.05.025

Yang H, Wang Y, Lai S et al (2007) Application of atomic force microscopy as a nanotechnology tool in food science. Wiley Online Libr. https://doi.org/10.1111/j.1750-3841.2007.00346.x

Vardhanabhuti B, Ikeda S (2006) Isolation and characterization of hydrocolloids from monoi (Cissampelos pareira) leaves. Food Hydrocoll 20:885–891. https://doi.org/10.1016/j.foodhyd.2005.09.002

Ikeda S (2003) Heat-induced gelation of whey proteins observed by rheology, atomic force microscopy, and Raman scattering spectroscopy. In: Food Hydrocolloids. Elsevier, pp 399–406

Ramos M, Valdés A, Beltrán A, Garrigós MC, Gelatin-based films and coatings for food packaging applications. https://doi.org/10.3390/coatings6040041

Acknowledgements

The authors express their sincere thanks to Dean, Fisheries College and Research Institute, Tamil Nadu, India, for permitting to carry out experiments in college laboratories. The authors express their sincere thanks to Director, ICAR- CIFT, Cochin, India, for providing support for the analysis of optical parameters. Thanks to the Professor and Head, TNJFU-Referral Laboratory of Fish Quality Monitoring and Certification, Fisheries College and Research Institute, Thoothukudi, India, for the support provided for the analysis of mechanical parameters. The authors also thank the Department of Chemistry, VOC College, Thoothukudi, India, for providing facilities and guiding in ATR-FTIR and AFM analysis. The authors also acknowledge the support from the Director, Bharat Ratna Prof. CNR Rao Research Centre, Coimbatore, India, for the analysis of XRD. The authors express their sincere thanks to the Prince of Songkla University and the National Research Council of Thailand for TGA analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare no competing interests.

Human and animal rights

This manuscript does not contain any kind of studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fathiraja, P., Gopalrajan, S., Karunanithi, M. et al. Process optimization and characterization of composite biopolymer films obtained from fish scale gelatin, agar and chitosan using response surface methodology. Polym. Bull. 80, 10775–10807 (2023). https://doi.org/10.1007/s00289-022-04540-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04540-4