Abstract

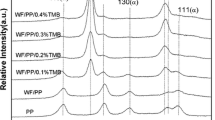

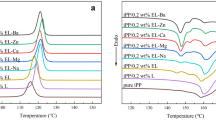

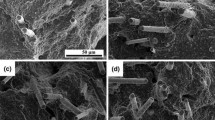

Isotactic polypropylene (PP) is a widely used and versatile commodity polymer with several polymorphs (α, β, γ). β-form isotactic PP attracted more interest due to its improved mechanical properties in comparison with the more common α-form. Addition of β-nucleating agents is an easy approach to induce β-form in isotactic PP. Few studies paid attention to the use of β-PP as the matrix of natural fiber/PP composites. In this study, isotactic PP was nucleated by a β-nucleating agent N, N’-dicyclohexylterephthalamide (TMB-5) and then melt compounded with poplar wood fiber (WF) to prepare WF/PP/TMB composites. The influence of adding different contents (0.05, 0.1, 0.15, 0.3 and 0.5%) of TMB-5 on the crystalline morphology, melting and crystallization behavior, mechanical properties and heating deflection temperature (HDT) of WF/PP composites was investigated. It was found that TMB-5 accelerated the crystal nucleation and induced β-crystal growth due to TMB-5 provided the nucleation site. The crystals size of WF/PP/TMB composite decreased and crystals boundaries became blurred with the increasing contents of TMB-5. The TMB-5 contents also affected the self-assembly morphology of TMB-5 which further influenced the morphology of crystals. The relative content of β-crystal (\({\mathrm{K}}_{\upbeta }\)) reached maximum value of 65.3% when the content of TMB-5 was 0.3%. But WF decreased \({\mathrm{K}}_{\upbeta }\) of PP/TMB under same content of TMB-5 which demonstrated the interference of WF with the generation of β-crystal. For mechanical properties, impact strength of WF/PP/TMB composite reached maximum value of 9.6 kJ·m−2 when adding 0.05% TMB-5. The TMB-5 contents had an insignificant effect on the flexural strength and modulus of WF/PP/TMB composite. Compressive strength of WF/PP/0.3%TMB composite reached maximum value of 64.4 MPa, which increased by 25.5% compared to WF/PP composite. Moreover, TMB-5 could improve the HDT of WF/PP composite as well. These results revealed that the addition of β-nucleating agent TMB-5 is an effective and practical method to improve crystallization rate and mechanical properties of WF/isotactic PP composites. WF/PP/TMB composite can be used in construction decoration, catering, automobile applications.

Similar content being viewed by others

References

Faruk O, Bledzki AK, Fink HP et al (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37(11):1552–1596

Sathishkumar GK, Ibrahim M, Akheel MM et al (2020) Synthesis and mechanical properties of natural fiber reinforced epoxy/polyester/polypropylene composites: a review. J Nat Fibers, pp 1–24

John M, Thomas S (2008) Biofibres and biocomposites. Carbohydr Polym 71(3):343–364

Malkapuram R, Yuvraj KV, Singh N (2008) Recent development in natural fiber reinforced polypropylene composites. J Reinf Plast Compos 28(10):1169–1189

Mohanty AK, Vivekanandhan S, Pin JM et al (2018) Composites from renewable and sustainable resources: Challenges and innovations. Science 362(6414):536–542

Kumar V, Tyagi L, Sinha S (2011) Wood flour–reinforced plastic composites: a review. Rev Chem Eng 27(5–6):253–264

Gurunathan T, Mohanty S, Nayak SK (2015) A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Composites Part A 77: 1–25

Sobczak L, Brueggemann O, Putz RF (2013) Polyolefin composites with natural fibers and wood-modification of the fiber/filler-matrix interaction. J Appl Polym Sci 127(1):1–17

Arbelaiz A, Fernández B, Ramos JA, Mondragon I (2006) Thermal and crystallization studies of short flax fibre reinforced polypropylene matrix composites: effect of treatments. Thermochim Acta 440(2):111–121

Kocic N, Kretschmer K, Bastian M et al (2012) The influence of talc as a nucleation agent on the nonisothermal crystallization and morphology of isotactic polypropylene: the application of the Lauritzen-Hoffmann, Avrami, and Ozawa theories. J Appl Polym Sci 126(4):1207–1217

Dong M, Guo Z, Su Z, Yu J (2011) The effects of crystallization condition on the microstructure and thermal stability of istactic polypropylene nucleated by β-form nucleating agent. J Appl Polym Sci 119(3):1374–1382

Li Y, Wen X, Nie M et al (2014) Controllable reinforcement of stiffness and toughness of polypropylene via thermally induced self-assembly of β-nucleating agent. J Appl Polym Sci 131(16)

Dong M, Guo ZX, Yu J et al (2009) Study of the assembled morphology of aryl amide derivative and its influence on the nonisothermal crystallizations of isotactic polypropylene. J Polym Sci Part B Polym Phys 47(3):314–325

Shi S, Zhang X, Liu Y et al (2016) Crystalline modification and morphology of polypropylene developed under the combined effects of montmorillonite and self-assembly β nucleating agent. Compos Sci Technol 135:76–82

Zhang Y, Sun T, Jiang W et al (2018) Crystalline modification of a rare earth nucleating agent for isotactic polypropylene based on its self-assembly. R Soc Open Sci 5(5)

Huang L, Wu Q, Li S et al (2018) Toughness and crystallization enhancement in wood fiber-reinforced polypropylene composite through controlling matrix nucleation. J Mater Sci 53(9):6542–6551

Han R, Li Y, Wang Q et al (2014) Critical formation conditions for β-form hybrid shish-kebab and its structural analysis. RSC Adv 4(110):65035–65043

Fu J, Li X, Zhou M et al (2018) The α-, β-, and γ-polymorphs of polypropylene–polyethylene random copolymer modified by two kinds of β-nucleating agent. Polym Bull 76(2):865–881

Huang L, Wang H, Wang W et al (2016) Non-isothermal crystallization kinetics of wood-flour/polypropylene composites in the presence of β-nucleating agent. J For Res 27(4):949–958

Jones AT, Aizlewood JM, Beckett DR (1964) Crystalline forms of isotactic polypropylene. Macromol Chem Phys 75(1):134–158

Rajkumar G, Sathishkumar GK, Srinivasan K et al (2021) Structural and mechanical properties of lignite fly ash and flax-added polypropylene polymer matrix composite. J Nat Fibers, pp 1–19

Li JX, Cheung WL (1998) On the deformation mechanisms of β-polypropylene:1. Effect of necking on β-phase PP crystals. Polymer 39 (26):6935–6940

Sathishkumar GK, Gautham G, Shankar GG et al (2021) Influence of lignite fly ash on the structural and mechanical properties of banana fiber containing epoxy polymer matrix composite. Polym Bull 79(1):285–306

Yang J, Gao M, Zhao H et al (2018) Space charge characteristics of polypropylene modified by rare earth nucleating agent for β crystallization. Materials (Basel) 12(1)

Coronado M, Blanco T, Quijorna N et al (2015) Types of waste, properties and durability of toxic waste-based fired masonry bricks. Eco Efficient Masonry Bricks Blocks, pp 129–188

Satya SK, Sreekanth PSR (2020) An experimental study on recycled polypropylene and high-density polyethylene and evaluation of their mechanical properties. Mater Today Proc 27:920–924

Acknowledgements

The work was financially supported by the National Natural Science Foundation of China (No. 31901250). The authors would like to thank PhD. Candidate Lei Zhang for his assistance in preparing the samples.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lv, C., Luo, S. & Guo, W. Investigation of the crystallization and mechanical properties of wood fiber/polypropylene composites nucleated by a self-assembly β-nucleating agent. Polym. Bull. 80, 5239–5256 (2023). https://doi.org/10.1007/s00289-022-04313-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04313-z