Abstract

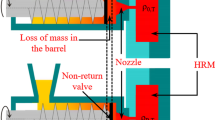

Thermoplastics processing usually involves the non-uniform cooling of molten polymer, which results in the presence of residual stresses in the final product. The magnitude of these stresses can be high enough to induce severe shape changes in the product, as well as changes in the overall material performance. Because of this, it is important to be able to accurately predict and measure them. In this study, the effect of coupling a kinetic model of crystallization on the prediction of thermal and pressure-induced residual stresses using the residual temperature field and formation pressure concepts is investigated. In addition, the effect of packing pressure on the deflection of injection molded polymer plates after ejection is reported. Simulation results were compared with experimental data, and it was found that considering crystallization in the prediction of residual stresses decreased the % error between predicted deflection and experimental results, from 0.52–7.34 to 3.0–56.3%. Also, good agreement between experimental results and the simulations performed using the residual temperature and pressure fields concepts in 2D while including a kinetic model of crystallization with different packing pressures.

Similar content being viewed by others

References

Thakkar BS, Broutman LJ (1980) The influence of residual stresses and orientation on the properties of amorphous polymers. Polym Eng Sci 20(18):1214–1219

Chaoui K, Chudnovsky A, Moet A (1987) Effect of residual stress on crack propagation in MDPE pipes. J Mater Sci 22:3873–3879

Hornberger LE, Devries KL (1987) The effect of residual stress on the mechanical properties of glassy polymers. Polym Eng Sci 27(19):1473–1478

Guevara-Morales A, Figueroa-López U (2014) Residual stresses in injection molded products. J Mater Sci 49:4399–4415

Baaijens FPT (1991) Calculation of residual stresses in injection molded products (in English). Rheola Acta 30(3):284–299. https://doi.org/10.1007/BF00366642

Daly HB, Nguyen K, Sanschagrin B, Cole K (1998) Build-up and measurement of molecular orientation, crystalline morphology, and residual stresses in injection molded parts: a review. J Inject Molding Technol (USA) 2(2):59–85

Isayev AI, Crouthamel DL (1984) Residual stress development in the injection molding of polymers. Polymer-Plastics Technol Eng 22(2):177–232. https://doi.org/10.1080/03602558408070038

Kamal MR, Lai-Fook RA, Hernandez-Aguilar JR (2002) Residual thermal stresses in injection moldings of thermoplastics: a theoretical and experimental study. Polym Eng Sci 42(5):1098–1114. https://doi.org/10.1002/pen.11015

Jansen KMB, Pantani R, Titomanlio G (1998) As-molded shrinkage measurements on polystyrene injection molded products. Polym Eng Sci 38(2):254–264. https://doi.org/10.1002/pen.10186

Jansen KMB, Van Dijk DJ, Freriksen MJA (1998) Shrinkage anisotropy in fiber reinforced injection molded products. Polym Compos 19(4):325–334. https://doi.org/10.1002/pc.10105

Wagner J, Phillips PJ (2001) The mechanism of crystallization of linear polyethylene, and its copolymers with octene, over a wide range of supercoolings. Polymer. 42(21):8999–9013

Phillips R, Manson JE (1997) Prediction and analysis of nonisothermal crystallization of polymers. J Polym Sci Part B: Polym Phys 35(6):875–888

Tropsa V, Ivankovic A, Williams JG (2000) Predicting residual stresses due to solidification in cast plastic plates. Plast, Rubber Compos 29(9):468–474

Tropsa V (2001) Predicting residual stresses due to solidification in cast plastic plates, PhD, Mechanical Engineering Department, Imperial College of Science, Technology and Medicine, London, UK

Jansen K (1994) Residual stresses in quenched and injection moulded products. Int Polym Proc 9(1):82–89

Estrella-Guayasamin M, Figueroa-López U, Guevara-Morales A (2019) Prediction of residual stresses in injection-molded plates using the residual temperature field concept. Polym Eng Sci 59(11):2220–2230. https://doi.org/10.1002/pen.25225

Zhang X, Fujii M (2003) Measurements of the thermal conductivity and thermal diffusivity of polymers. Polym Eng Sci 43(11):1755–1764

Choe CR, Lee KH (1989) Nonisothermal crystallization kinetics of poly (etheretherketone) (PEEK). Polym Eng Sci 29(12):801–805

Tobin MC (1974) Theory of phase transition kinetics with growth site impingement. I. homogeneous nucleation. J Polym Sci 12:399–406

Zoetelief WF, Douven LFA, Ingen Housz AJ (1996) Residual thermal stresses in injection molded products. Polym Eng Sci 36(14):1886–1896

Huang M-C, Tai C-C (2001) The effective factors in the warpage problem of an injection-molded part with a thin shell feature. J Mater Process Technol 110(1):1–9. https://doi.org/10.1016/S0924-0136(00)00649-X

Acknowledgements

The authors would like to gratefully acknowledge the financial support from the Mexican National Council for Science and Technology (CONACyT).

Author information

Authors and Affiliations

Contributions

ME-G: Investigation, other contributions. UF-L: Conceptualization, Methodology, Supervision, Formal Analysis. AG-M: Conceptualization, Methodology, Supervision, Formal Analysis, Writing–Review and Editing. RAG-L: Formal Analysis, Writing Original draft and Editing.

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest to this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Estrella-Guayasamin, M., Figueroa-López, U., Guevara-Morales, A. et al. Effect of crystallization and packing pressure on the development of residual stresses on injection molded polypropylene samples. Polym. Bull. 80, 4355–4369 (2023). https://doi.org/10.1007/s00289-022-04276-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04276-1