Abstract

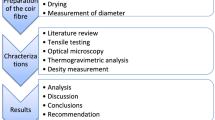

Natural fibres such as coir, jute, flax, and hemp have been considered for technical applications. These fibres, though with some desirable qualities such as low density and environmental compatibility, possess the common property of non-uniformity along their length and, as a result, variable diameter and variable cross-sectional area. Several other factors, such as gauge length, fibre species and origin, strain rate, method of extraction of the fibres, porosity and pore size distribution, have been identified to influence the tensile strength of natural fibres and limit their applications in composites. Besides, several authors have used different diameters for the same type of natural fibre, such as coir, resulting in significant inconsistency in the tensile properties. For the same type of coir fibre, and from tensile strength reports from ten authors, an average tensile strength of 120.97 ± 42.30 MPa was obtained. The average number of fibres used in most cases for the tensile test was less than the requirement for natural fibres. All these factors were addressed with the aim of improving the overall properties of natural fibres and their composites.

Similar content being viewed by others

Introduction production, properties and applications of natural fibres and their composites

The awareness of the depletion of crude oil in addition to new legislation regarding the reduction of carbon footprint and enhanced consumer pressure coupled with the sustainability concept has increased the search for natural material as an alternative [1,2,3].

With reference to Fig. 1, natural fibres are in abundance with a yearly production of about 22.6 × 106 tonnes. Jute fibre maintained the lead for five consecutive years. Within this period, the quantity of jute fibre produced stood at 77.78% of the total yearly average production, followed by coir with 26.53% and sisal with 6.18%. The compound annual growth rate (CAGR) of natural fibre within this period was 0.64%. In 2019, coir fibre topped the chart with a total volume of production of 1,000,000 tonnes [4].

World productions of natural fibres 2012–2017; adapted from [5]

Though the properties of natural fibres such as the tensile strength and stiffness have been reported to be too low (see Table 1) to compete effectively with synthetic fibres, yet they are making significant inroads in various industrial sectors. Figure 2 shows the use of natural fibres as reinforcements in composites for various applications. They have a lower density than glass and most synthetic fibres and therefore offer significant weight savings and fuel efficiency when compared with synthetic fibres [6, 7]. This lightweight advantage has propelled their adoption in the automotive sector such that natural fibre-reinforced composites are currently used in vehicle interior parts such as seatback, interior door panels, spare tyre covers, package trays, map boxes, seat liners and sunroof frames which weighs 50% less than a metal sunroof frame [7, 8]. Figure 3 shows a continuous growth in commercial motor vehicle production up to 2018. A slight drop of 2% was witnessed in 2019 as a result of the onset of Covid-19 and a significant drop of 13% in 2020 due to the full-blown Covid-19 pandemic; however, in 2021, a recovery of 5% was experienced, it is expected that production and demand for natural fibres will continue to increase. The building, construction and sporting sectors are equally involved in the use of natural fibre composites. Audio components and Cellucomp fishing rods found in the leisure industry are based on natural fibres [8].

Applications of natural fibre composites in different sectors adapted from [27]

the International organization of motor vehicle manufacturers (OICA) [28]

Global commercial vehicle production showing continuous growth in the automobile industry adapted from

Also, the energy sector is not left out, owing to higher energy demand and consumption, and energy-related CO2 emissions, investigations into the properties of cellulosic fibres and their composites, as well as recycling of wastes for composites applications, have increased. Environmentally friendly biosourced materials for use in energy applications have been proposed by several researchers [9,10,11]. Li–O2 batteries have been reported to be used to solve part of the energy challenges; however, it possesses some problems of poor stability and some safety issues [12]. The use of cellulose with carboxylated polyimide nanofibre as a separator for lithium-ion battery application has been reported to be more environmentally friendly than the use of pristine polyimide (PI) only. Besides, higher tensile strength and better wettability were reported using cellulose with carboxylated polyimide as a separator than using only a pristine PI separator [13]. A similar observation was made by [14]. The use of an environmentally friendly high-performance Zn-air rechargeable battery using cellulose biodegradable feedstock as additives and diaphragm showed an increase in the viscosity of the electrolyte and a decrease in water evaporation resulting in a more stable cell operation [15].

Sustainability and availability of raw materials have been counted as part of the drivers in the use of natural fibre composites. Besides low density, natural fibres possess high specific properties (property/density) (see Table 1). Furthermore, natural fibres in composites have displayed excellent acoustic and thermal properties when compared with synthetics fibres such as carbon and glass, low tool wear performance, no off-gassing of toxic compounds and positive effects on agriculture [7, 16].

The basic chemical components of natural fibres are hemicellulose, cellulose, lignin and pectin, as displayed in Table 1. The nature of these chemical compositions varies from fibre to fibre. The properties of each of the chemical components influence the overall properties of the fibre. The cellulose, hemicellulose (HC) and lignin are interconnected. Cellulose content has been associated with the strength of the fibre. Hemicellulose has been associated with an affinity for moisture, thermal degradation and biodegradation as a result of its low crystallinity and low degree of polymerisation; lignin is rather a complex molecule with a three-dimensional structure confirmed to be amorphous and, as a result, displays moisture-dependent properties [29]. The cellulose content of the fibres is in the range 48.6–74.4%, the lignin content 30.4%, whereas the hemicellulose, pectin and moisture contents are in the ranges 8.2–22.4%, respectively.

The average yearly production of synthetic fibres from 2015 to 2019 was 72 million metric tonnes, as shown in Fig. 4. A CAGR of 2.55% was recorded. This yielded 42 million metric tonnes higher than the average yearly production of natural fibres.

Level of production of natural fibres in comparison with synthetic fibres adapted from [4]

The annual average production of synthetic fibres far outweighs that of natural fibres. The reason is that synthetic fibres, such as carbon and glass, are still in very high demand owing to their superior performance properties such as high specific tensile strength and stiffness, uniform diameter, as well as established manufacturing techniques. Natural fibres are still far behind synthetic fibre composites, both in production and in application owing to several reasons.

Overall issues associated with natural fibre and their composites

Although natural fibres are given considerations as a potential replacement for synthetic fibres, they possess some limitations: lack of technical advancements in the raw materials manufacturing process, non-availability of enhanced equipment in the processing of natural fibres, which reduces efficiency and rate of production, incompatibility of the natural fibre surface functional group with the functional group of the existing hydrophobic resins systems in different end-use sectors, resulting into poor fibre–matrix interfacial adhesion with poor load-transfer efficiency [7, 30]. Natural fibres can begin to degrade at temperatures within the range of 170–200 °C [31,32,33]. As a consequence, there exists a drawback in the use of natural fibres as reinforcement in some thermoplastic matrices of high melting temperatures. Variability in their mechanical properties is influenced by several factors, such as lack of standardization in processing and surface treatments. Their susceptibility to moisture absorption and poor wettability has been mentioned as the downsides in the use and application of natural fibres [6, 34,35,36]. The presence of moisture gives room for dimensional variations of the end product, and this also causes weakness in the interfacial bond between the fibre and the matrix [37]. An often-overlooked, but significant hindrance to the wide use of natural fibres in composites application is restricted access due to geographical barriers between the countries where natural fibres are grown and countries where they are used as reinforcements in composites production such as North America, the UK, France, Germany and Spain. Poor fibre orientation and aspect ratio such as found in natural fibre give rise to poor mechanical properties of the resulting composite [38]. Natural fibres are usually twisted during fabrication, leading to poor impregnation of the resin and subsequent poor mechanical properties [39]. The presence of void in natural fibres has been reported to decrease the mechanical properties of the resulting composites as void content increases with increasing reinforcement [40, 41].

Relatively poor tensile strength of natural fibres: a major concern

Investigations into the tensile strengths of natural fibres have been carried out and reported by several researchers. Variability in the tensile strength of natural fibres is a source of serious concern. On matured brown coir fibres alone, different authors reported different tensile strengths, as shown in Fig. 5, the average tensile strength is 132.41 ± 48.06 MPa.

A number of factors have been identified to exert influence on the tensile strength of natural fibres.

Strength as a function of the diameter of the fibre

Natural fibres possess a common property of non-uniformity along their length and, as a result, have a variable diameter and variable cross-sectional area. The mechanical properties of natural fibres, such as the tensile strength, have been reported to be a function of their equivalent diameter. The diameter of the fibre has also been linked to the interfacial shear strength \(\tau ,\) as stated in Eq. (1) [49, 50]:

where d is the diameter of the fibre, Fmax is the debonding force, and le is the embedded length of the fibre in the matrix. The inverse relationship between the tensile strength and the fibre diameter has been reported consistently for most lignocellulosic fibres [42, 49, 51]. In this respect, [52] suggested a hyperbolic inverse correlation of strength and diameter with evidence from nine different types of natural fibres as:

where \(\sigma\) is the variation of strength, d is the diameter of the fibre, and A and B are constants.

Griffith’s model displays an indirect proportionality between Young’s modulus and the fibre diameter as shown in Eq. 3:

where A and B are constants,\(d_{f}\) = diameter of the fibre and \(E_{f} \left( {d_{f} } \right)\) = Young’s modulus or property analysed.

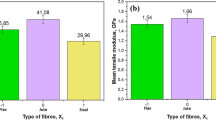

Reported an increase in the tensile strength from 48.45 to 134.41 MPa as the fibre diameter decreased. Studies carried out by [42] on the lignocellulosic fibres from Brazil revealed a similar trend. The explanation is that natural fibres are non-uniform, with intrinsic diameters. The thicker the fibre, the more the flaws and irregularities it contains and the thinner the fibre, the fewer flaws and irregularities or defects present [18, 52]. Therefore, as the diameter of the fibre increases, the probability of the number of defects present will increase. Besides, different authors use different diameters for the same type of fibre such as coir, as shown in Fig. 6; thus, an average of 229.63 ± 89.96 mm results in variations in the tensile strengths.

In addition, several authors have used fibres much less than the minimum number required, for the same fibre, for example, in coir, as shown in Fig. 7 hence an average of 17 ± 10 fibres, while many did not state the number of fibres used from which the average diameter for tensile tests was obtained.

Strength as a function of the gauge length of the fibre

The tensile strength of fibres has been associated with their gauge length. Several researchers have reported the influence of gauge length on the tensile properties of reinforcing fibres. The tensile strength has been observed to increase with a decrease in the gauge length [22, 24, 51, 54]. It follows similar trends as with the fibre diameter: the longer the gauge length, the higher the probability of the presence of flaws and, as a result, a decrease in tensile strength. As the sample gauge length gets longer, the strength of the sample decreases and vice versa as shown in Fig. 8.

Several authors have reported that the reason for this relationship is as a result of the number of defects and so the weak links present in the fibre. The incremental change in strength \(d\sigma\) of the fibre with a corresponding change in gauge length \(dL\) according to [51] is represented by Eq. (4):

where \(\sigma\) is the strength of the fibre, \(\propto\) is a measure of the frequency of occurrence of weak links, and L is the gauge length.

The general nature for change in strength with change in gauge length is thus given by integrating Eq. (4), where the strength of the fibre of length L is represented by \(\sigma_{o}\):

The slope of the tensile strength versus gauge length yields the defect density [18, 42]. However, varying gauge lengths have been used by different researchers for the same type of natural fibre, such as coir, as shown in Fig. 9, giving rise to inconsistencies in the tensile strength.

Strength as a function of the strain rate

Different authors have reported the influence on the tensile properties of coir fibre as a result of the strain rate [22, 24, 42] and observed that the speed of testing had the predominant effect on the ultimate tensile strength of the fibre. It has been previously noted that the diameter, as well as the gauge length, is also contributory factors to the tensile strength variations. A strain rate dependency of the fibre reinforcement with respect to the fibre diameter was observed by [59].

Strength as a function of the density of defects present in the fibre

Defects present in natural fibres have been identified as a major detrimental influence on the tensile strength of natural fibres. The extent of defects in natural fibres varies according to the diameter of the fibre. Fibres with higher cross sections display a higher density of defects or irregularities both internal and external than fibres with lower cross sections. Larger diameter fibres, therefore, possess weaker points than thinner-diameter fibre. Fibres with a lower cross-sectional area have been found to be of more uniformity with lower porosity and hence fewer defects and therefore higher strength [60]. The slope of the plot of tensile strength against test length gives an indication of the defect density [54]. Investigations on the defect density of white coir, brown coir, bamboo and jute were conducted, and it was found that their defect densities are in the decreases in the order: bamboo, brown coir, jute and white coir [60]. This was attributed to the extraction method adopted, which suggested that the steam explosion extraction of the bamboo fibres introduced significant defects, whereas the mechanical extraction of white coir caused the least defects.

Strength as a function of the porosity and microfibril angle of the fibre

The poor tensile strength of natural fibres has been reported by several authors to originate from its microstructure, such as the porosity and pore size distribution [61, 62], see Fig. 10 as well as different cellulose and lignin contents (Table 1).

Strength as a function of age, species, origin and method of extraction of fibre

Investigations into the properties of natural fibres of the same type, but different origins, species and maturity have been carried out. Observations revealed that the properties of natural fibres are largely as a result of the soil type in which they are grown, plant species, age, origin and extraction method [24, 42, 63]. Coir fibres of different varieties and different ages but of Philippine origin were investigated by [63]. These fibres were extracted manually from the husk. The varieties were compared with retted coir fibres from India. It was observed that the tensile strength of the retted India coir fibre was 248 MPa, while the strongest fibre of all the species of the manually extracted Philippine coir fibre was 114 MPa. The different species also showed significant variations in strength.

Strength as a function of the degree of moisture absorbability of the fibres

Several reports have confirmed the susceptibility of natural fibres to moisture. The poor resistance to moisture ingress of natural fibres has been reported to reduce the potentials of natural fibres to be used as reinforcements in composites. Moisture ingress reduces the crystallinity of the fibre, weakens the interfacial bond strength, gives rise to swelling and promotes microcracks in the composites [64,65,66,67].

Moisture ingress in cellulosic fibres has been reported by [65]. The moisture ingress is accelerated via capillary action through the pores present in natural fibres [68]. [69, 70] determined the changes in the thickness and overall volume caused by moisture ingress using the following equation:

where the change in the relative thickness or thickness swelling percentage, thickness at time t, and the initial thickness are represented by \(T_{{{\text{re}}}}\),\(T_{i}\) and \(T_{o} ,\) respectively.

where the relative change in volume or volume swelling, volume at time t and the initial volume are represented by \(V_{{{\text{re}}}}\), \(V_{i}\) and \(V_{o}\), respectively.

Water ingress was calculated as a percentage using the difference in weight as follows:

The relative change in weight (water absorption in percentage), the weight at time t, the initial weight at t = 0 and the soaking time are represented by \(W_{e}\),\(W_{i}\), \(W_{o}\) and t, respectively. [69, 71] observed that changes in the thickness recorded as a result of moisture ingress are affected by time and type of epoxy specimens matrix as well as the type of fibre. [68, 69, 72] noted that the degree of changes in the thickness varies from fibre to fibre and the ratio of fibre to the matrix in the composite, ascertaining that, as the fibres get swollen, stress is exerted on the matrix, which can lead to the composite undergoing micro-cracking, reduction in strength and subsequent failure.

However, moisture absorption of natural fibres can be minimised by several processes such as coating [67, 73], treatment with chemicals such as NaOH, acetylation, toluene diisocyanate, silane on alkali [64, 74,75,76,77], use of coupling agents such as maleated anhydride grafted polypropylene (MAPP), maleic anhydride polyethylene (MAPE), silane [63, 78, 79]. A decrease in water absorption in coir fibres after surface treatments using NaOH, silane and alkalized silane was reported [73].

Coupling agents improve the adhesion between fibre and matrix, thus aiding in reacting with the hydroxyl group and decrease in the rate of the diffusion process and hence reduction in moisture ingress [68, 73, 79]. Coatings such as latex coatings act in a similar way as coupling agents by partially shielding the pores on the surface of the fibre, thus reducing the penetration of moisture into the fibre. Hence, a decrease in moisture ingress has been recorded for latex-coated fibres. A decrease in moisture ingress has been observed after treatment with gamma-ray irradiation, which has been noted to decrease the capillary action resulting in reduced sorption. Chemical treatments such as NaOH and acetylation have been reported to decrease moisture ingress, thus reducing the absorption of moisture through the capillary [21, 78, 80].

Moisture ingress increases as the fibre content increases because the cellulose content becomes higher, and subsequently, there are more fibre-to-fibre interactions. Fibre type, geometry and size distribution influence moisture intake: smaller diameters and more uniformity across the size of the fibre lead to reduction in moisture uptake by narrowing transport pathways between contacting fibres [66, 79].

Considering the structure of coir, with numerous pores and high level of porosity in its untreated form, it may therefore be expected that coir fibres will be more prone to moisture absorption than sisal and jute, which are more compact with less porosity, but this is not the case. The cellulose content of coir, as shown in Table 1, is much less than that of several natural fibres such as sisal and jute, since there are fewer free OH groups. It is expected that coir fibres within specific diameters or geometry will be much less prone to moisture ingress than most natural fibres upon treatments with chemicals and coupling agents.

Even the advanced high-profile synthetic fibres such as aromatic polyamide or aramid fibres are also susceptible to moisture. An increase in volume fraction of aramid fibre results in an increase in water absorption [81]. Nevertheless, aramid fibre is still a material of choice for high-performance applications. However, what needs to be ascertained as pointed out by [82] is to what degree does the moisture influence the mechanical properties of composites manufactured with aramid fibre? This question can as well be applied to natural fibre composites to achieve optimum properties.

There exist several conflicting reports on the effects of moisture ingress on the mechanical properties of natural fibres. These reports are based on the fact that the mechanical performance of natural fibres is grossly dependent on the fibre type and is therefore a function of their chemical structure, microfibrillar angle and cellulose content. Upon absorption of water, the tensile strength decreases. An approximate 30% decrease was observed in salt-water sorbed fibres, as well as desorbed fibres display similar effects. An increase in elongation to failure of fibre consequent upon sorption has been reported. This is so because the amorphous phase becomes favoured in the swollen stage, the lignin-cellulose network is disrupted by the presence of water molecules [38, 73, 83]. On the contrary, [79] reported an increase in tensile strength of water-absorbed flax fibre and hemp unsaturated polyester composites samples, respectively, with a higher increase as the fibre content increases when compared to dry samples. This was attributed to the swelling of the fibre owing to moisture absorption and subsequent closure of gaps possibly created during processing. Similar reports were published for jute fibre-reinforced unsaturated polyester composites [84, 85]. The increase in strength was connected to the filling up of the gaps achieved during manufacturing processes as a result of the swelling of the fibre. The swollen fibre fills the gaps exerting pressure on the matrix, and hence, there is an improved adhesion with more efficient stress transfers. An increase in elongation at break was also reported by the authors. An increase in strength, Young’s modulus and elongation at break after treatment of wood pulp composites with maleated polyethylene (MAPE) coupling agent has been reported. MAPE increased the interfacial bond strength, leading to an increase in the load transfer efficiency, and hence, an increase in the mechanical properties was reported [79]. However, [77] reported a sharp decrease in the tensile strength of both alkali-treated and untreated Napier grass fibre composites. This was attributed to poor stress transfer owing to poor interfaces between the fibre and the matrix. Poor interfaces have been associated with the wettability of the reinforcing fibre.

Wettability of natural fibres for enhanced strength in the composite

In the manufacture of natural fibre composites, a fibre–resin interface is created. The mechanical properties of the final product are subject to how well the resin wets the fibre. It is therefore ideal to determine the wettability of fibre in readiness for manufacturing composites. Poor wetting has been reported as one of the drawbacks in the use of natural fibres as reinforcements [86]. Investigations into wetting coupled with surface chemistry of natural fibres enhance the characterisation of the fibre surface, and this contributes to the selection of the best-suited treatments for the fibre and modification of the surface energy of the fibre matrix giving rise to an improved fibre–resin interface [87]. Wetting is relevant to fibre–matrix adhesion. The level of adhesion controls the efficiency of stress transfer from the resin to the fibre at the interface region [88]. The wettability of the fibre surface can be measured by the contact angle. The contact angle is the angle formed at the intersection of the liquid–solid interface or liquid–vapour interface [89,90,91]. The lower the contact angle, the higher the wettability and vice versa, as in the case of coir and the higher the adhesion ability of the fibre onto the matrix. Better wettability is achieved as the contact angle approaches zero [89, 90, 92,93,94].

Reports have indicated that a high concentration of lignin or the presence of hemicelluloses and extractives on the fibre surface contributes to a large extent to their wettability [87, 95, 96]. Another interfacial characteristic of lignin is that it lowers the adhesion of water to the surface. Lignin forms granules in water, these granules are so strong that they do not spread out to form a film on the substrates, but rather bind to the substrates through electrostatic interactions. Therefore, the wetting properties are subject to the morphology of adsorbed layer and the location of bare lignin in the adsorbed layer [97, 98]. The adhesion at the fibre–matrix interface can be explained through an interaction of physical adhesion through a good wettability between the fibre and the matrix, and chemical bonding with mechanical interlocking is also essential for good interfacial adhesion. However, these interactions are dependent on the functional groups on the surface of the fibre and matrix at the interfacial contact area [99].

The level of adhesion of fibre and matrix is determined by their interfacial shear strength (IFSS). The IFSS can be improved by subjecting the fibre to chemical treatment such as NaOH treatment. The interfacial shear strength for sisal, jute, hemp has been noted to increase upon treatments with NaOH, sodium bicarbonate (NaHCO3) and maleic anhydride polypropylene (MAPP) [92,93,94].

Conclusions

Several factors such as fibre diameter, gauge length, fibre species and origin, strain rate, method of extraction of the fibres, porosity and pore size distribution have been identified among other factors to influence the tensile strength of natural fibres. Other reasons include lack of technical advancements in the raw materials manufacturing process, non-availability of enhanced equipment in the processing of natural fibre which reduces efficiency and rate of production, incompatibility of the natural fibre surface functional group with the functional group of the existing hydrophobic resins systems in different end-use sectors, resulting to poor fibre–matrix interfacial adhesion with poor load-transfer efficiency. Another drawback is the lack of standardization in processing and surface treatments of natural fibres. Their susceptibility to moisture absorption and poor wettability has been mentioned as the downsides in the use and application of these fibres.

These findings have highlighted the areas of concentration for subsequent researchers to come up with improved properties of natural fibres and natural fibre composites for more advanced applications.

References

Bledzki AK, Gassan J (1999) Composites reinforced with cellulose based fibres. Prog Polym Sci 24(2):221–274

Yang Y, Boom R, Irion B, van Heerden DJ, Kuiper P, de Wit H (2012) Recycling of composite materials. Chem Eng Process Process Intensif 51:53–68

Ho M, Wang H, Lee J-H, Ho C, Lau K, Leng J et al (2012) Critical factors on manufacturing processes of natural fibre composites. Compos Part B Eng 43(8):3549–3562

Rijavec T (2019) Natural fibres and the world economy–discover natural fibres initiative 2017–9, Available from: http://dnfi.org/abaca/natural-fibres-and-the-world-economy_1778/

Food and agriculture organization corporate statistical database (2018), List of countries by coconut production, faostat 1–5, Available from: http://www.fao.org/faostat/en/#data/QC/

Peças P, Carvalho H, Salman H, Leite M (2018) Natural fibre composites and their applications: a review. J Compos Sci 2(4):66

Chauhan V, Kärki T, Varis J (2019) Review of natural fiber-reinforced engineering plastic composites, their applications in the transportation sector and processing techniques. J Thermoplas Compos Mat. https://doi.org/10.1177/0892705719889095

Suddell BC (2008) Industrial fibres: recent and current developments. Proc Symp Nat Fibres 44:71–82

Aziz SB, Abidin ZHZ (2013) Electrical conduction mechanism in solid polymer electrolytes: new concepts to arrhenius equation. J Soft Matter 2013:1–8. https://doi.org/10.1155/2013/323868

Subban RHY, Arof AK, Radhakrishna S (1996) Polymer batteries with chitosan electrolyte mixed with sodium perchlorate. Mater Sci Eng B 38(1–2):156–160

Colò F, Bella F, Nair JR, Destro M, Gerbaldi C (2015) Cellulose-based novel hybrid polymer electrolytes for green and efficient Na-ion batteries. Electrochim Acta 174:185–190

Amici J, Torchio C, Versaci D, Dessantis D, Marchisio A, Caldera F, Bodoardo S (2021) Nanosponge-based composite gel polymer electrolyte for safer Li–O2 batteries. Polymers 13(10):1625

Deng J, Cao D, Yang X, Zhang G (2022) Cross-linked cellulose/carboxylated polyimide nanofiber separator for lithium-ion battery application. Chem Eng J 433(P3):133934

Piana G, Ricciardi M, Bella F, Cucciniello R, Proto A, Gerbaldi C (2020) Poly (glycidyl ether) s recycling from industrial waste and feasibility study of reuse as electrolytes in sodium-based batteries. Chem Eng J 382:122934

Nagy T, Nagy L, Erdélyi Z, Baradács E, Deák G, Zsuga M, Kéki S (2022) Environmentally friendly high performance Zn-air rechargeable battery using cellulose derivatives: a 3D-printed prototype. J Energy Storage 49:104173

Karus M, Kaup M (2002) Natural fibres in the European automotive industry. J Ind Hemp 7(1):119–131

Gassan J, Bledzki AK (1999) Possibilities for improving the mechanical properties of jute/epoxy composites by alkali treatment of fibres. Compos Sci Technol 59(9):1303–1309

Satyanarayana KG, Sukumaran K, Mukherjee PS, Pillai SGK (1986) Materials science of some lignocellulosic fibers. Metallography 19(4):389–400

Ticoalu A, Aravinthan T, Cardona F (2010) A review of current development in natural fiber composites for structural and infrastructure applications. South Reg Eng Conf 1997:13

Saheb N, Jog J (2015) Natural fiber polymer composites : a review. Adv Polym Technol 2329:351–63

Kabir MM, Wang H, Lau KT, Cardona F, Aravinthan T (2012) Mechanical properties of chemically-treated hemp fibre reinforced sandwich composites. Compos Part B: Eng 43(2):159–169

Alves Fidelis ME, Pereira TVC, Gomes ODFM, De Andrade SF, Toledo Filho RD (2013) The effect of fiber morphology on the tensile strength of natural fibers. J Mater Res Technol 2(2):149–57

Shahzad A (2013) A study in physical and mechanical properties of hemp fibres. Adv Mater Sci Eng 2013:2013

Mathura N, Cree D (2016) Characterization and mechanical property of Trinidad coir fibers. J Appl Polym Sci 133(29):1–9

Sanjay MR, Yogesha B (2016) Studies on mechanical properties of jute/e-glass fiber reinforced epoxy hybrid composites. J Miner Mater Charact Eng 04(01):15–25

Nguyen TT, Indraratna B (2017) Experimental and numerical investigations into hydraulic behaviour of coir fibre drain. Can Geotech J 54(1):75–87

Adekomaya O (2020) Adaption of green composite in automotive part replacements: discussions on material modification and future patronage. Environ Sci Pollut Res 27(8):8807–13

Persson K (2000) Macromechanical modelling of wood and fibre properties, PhD Thesis, Lund University

Rohit K, Dixit S (2016) A review - future aspect of natural fiber reinforced composite. Polym Renew Resour 7(2):43–60

Dicker MPM, Duckworth PF, Baker AB, Francois G, Hazzard MK, Weaver PM (2014) Green composites: a review of material attributes and complementary applications. Compos Part A Appl Sci Manuf 56:280–9

Van Dam JEG, Van Den Oever MJA, Teunissen W, Keijsers ERP, Peralta AG (2004) Process for production of high density/high performance binderless boards from whole coconut husk. part 1: lignin as intrinsic thermosetting binder resin. Ind Crops Prod. 19(3):207–16

Ezekiel N, Ndazi B, Nyahumwa C, Karlsson S (2011) Effect of temperature and durations of heating on coir fibers. Ind Crop Prod 33(3):638–43

Jayamani E, Loong TG, Khusairy M, Bakri B (2020) Comparative study of fourier transform infrared spectroscopy ( FTIR ) analysis of natural fibres treated with chemical, physical and biological methods. Polym Bull 77(4):1605–29

Azwa ZN, Yousif BF, Manalo AC, Karunasena W (2013) A review on the degradability of polymeric composites based on natural fibres. Mater Des 7:424–42

Hariprasad T, Dharmalingam G, Praveen Raj P (2013) Study of mechanical properties of banana-coir hybrid composite using experimental and fem techniques. J Mech Eng Sci 4:518–31

Bisanda ETN, Ansell MP (1991) The effect of silane treatment on the mechanical and physical properties of sisal-epoxy composites. Compos Sci Technol 41(2):165–178

George J, Sreekala MS, Thomas S (2001) A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym Eng Sci 41(9):1471–85

Li Y, Ma H, Shen Y, Li Q, Zheng Z (2015) Effects of resin inside fiber lumen on the mechanical properties of sisal fiber reinforced composites. Compos Sci Technol 108:32–40

Arrakhiz FZ, El AM, Kakou AC, Vaudreuil S, Benmoussa K, Bouhfid R et al (2012) Mechanical properties of high density polyethylene reinforced with chemically modified coir fibers: impact of chemical treatments. J Mater 37:379–83

Li Y, Mai Y, Ye L (2000) Sisal fibre and its composites: a review of recent developments. Compos Sci Technol 60:2037–55

Tomczak F, Sydenstricker THD, Satyanarayana KG (2007) Studies on lignocellulosic fibers of Brazil, part II: morphology and properties of Brazilian coconut fibers. Compos Part A Appl Sci Manuf 38(7):1710–21

Jústiz-Smith NG, Virgo GJ, Buchanan VE (2008) Potential of Jamaican banana, coconut coir and bagasse fibres as composite materials. Mater Charact 59(9):1273–8

Cheung H, Ho M, Lau K, Cardona F, Hui D (2009) Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Compos Part B Eng 40(7):655–63

Rahman MM, Khan MA (2007) Surface treatment of coir (Cocos nucifera) fibers and its influence on the fibers’ physico-mechanical properties. Compos Sci Technol 67(11–12):2369–76

Mir SS, Hasan SMN, Hossain MJ, Hasan M (2012) Chemical modification effect on the mechanical properties of coir fiber. Eng J 16(2):73–83

SyukranAlhelmySeriBuana M, Pasbaskhsh P, Goh KL, Bateni F, Haris MRHM (2013) Elasticity, microstructure and thermal stability of foliage and fruit fibres from four tropical crops. Fibers Polym 14(4):623–9

Mudhafar A, Kadhim J (2016) Tensile properties distribution of coir natural fiber using weibull statistics. Eng & TechJournal 34(6):1080

Fiore V, Scalici T, Nicoletti F, Vitale G, Prestipino M, Valenza A (2016) A new eco-friendly chemical treatment of natural fibres: effect of sodium bicarbonate on properties of sisal fibre and its epoxy composites. Compos Part B Eng 85:150–60

Jawaid M, Khalil HPSA, Bakar AA (2010) Mechanical performance of oil palm empty fruit bunches / jute fibres reinforced epoxy hybrid composites. Mater Sci Eng A 527(29–30):7944–9

Mukherjee PS, Satyanarayana KG (1984) Structure and properties of some vegetable fibres-part 1 sisal fibre. J Mater Sci 19(12):3925–34

Monteiro SN, Lopes FPD, Barbosa AP, Bevitori AB, Amaral Da Silva IL, Da Costa LL (2011) Natural lignocellulosic fibers as engineering materials-An overview. Metall Mater Trans A Phys Metall Mater Sci 42(10):2963–74

Brígida AIS, Calado VMA, Gonçalves LRB, Coelho MAZ (2010) Effect of chemical treatments on properties of green coconut fiber. Carbohydr Polym 79(4):832–8

Defoirdt N, Biswas S, De VL, Tran LQN, Van AJ, Ahsan Q et al (2010) Assessment of the tensile properties of coir, bamboo and jute fibre. Compos Part A Appl Sci Manuf 41(5):588–95

Nam TH, Ogihara S, Tung NH, Kobayashi S (2011) Effect of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly(butylene succinate) biodegradable composites. Compos Part B Eng 42(6):1648–56

Kulkarni AG, Satyanarayana KG, Rohatgi PK (1983) Weibull analysis of strengths of coir fibres. Fibre Sci Technol 19(1):59–76

Pavithran C, Mukherjee PS, Brahmakumar M (1991) Coir-glass intermingled fibre hybrid composites. J Reinf Plast Compos 10:91–101

Prasad SV, Pavithran C, Rohatgi PK (1983) Alkali treatment of coir fibres for coir-polyester composites. J Mater Sci 18(5):1443–54

Kim T, Oshima K, Kawada H (2013) Impact tensile properties and strength development mechanism of glass for reinforcement fiber. J Phys Conf Ser 451:012006. https://doi.org/10.1088/1742-6596/451/1/012006

Monteiro SN, Calado V, Margem FM, Rodriguez RJS (2012) Thermogravimetric stability behavior of less common lignocellulosic fibers-a review. J Mater Res Technol 1(3):189–99

Ozturk AU (2007) Microstructural investigation on the relationship between microstructure and compressive strength of cement mortars. Comput Mater Sci 41(2):127–33

Burgert I (2007) Exploring the michromechanical design of plant cell wall. Am J Bot 93(10):1391–401

van Dam JEG, van den Oever MJA, Keijsers ERP, van der Putten JC, Anayron C, Josol F et al (2006) Process for production of high density/high performance binderless boards from whole coconut husk, part 2: coconut husk morphology, composition and properties. Ind Crops Prod 24(2):96–104

Sreekala MS, George J, Kumaran MG, Thomas S (2002) The mechanical performance of hybrid phenol-formaldehyde-based composites reinforced with glass and oil palm fibres. Compos Sci Technol 62(3):339–53

Iqbal M, Sohail M, Ahmed A, Ahmed K, Moiz A, Ahmed K (2012) Textile environmental conditioning: effect of relative humidity variation on the tensile properties of different fabrics. J Anal Sci Methods Instrum 02(02):92–7

Muñoz E, García-Manrique JA (2015) Water absorption behaviour and its effect on the mechanical properties of flax fibre reinforced bioepoxy composites. Int J Polym Sci 2015:16–8

Londhe R, Mache A, Kulkarni A (2016) An experimental study on moisture absorption for jute-epoxy composite with coatings exposed to different pH media. Perspect Sci 8:580–2

Ashori A, Sheshmani S (2010) Hybrid composites made from recycled materials: moisture absorption and thickness swelling behavior. Bioresour Technol 101(12):4717–20

Masoodi R, Pillai KM (2012) A study on moisture absorption and swelling in bio-based jute-epoxy composites. J Reinf Plast Compos 31(5):285–94

Yahaya R, Sapuan SM, Jawaid M, Leman Z, Zainudin ES (2016) Effect of fibre orientations on the mechanical properties of kenaf–aramid hybrid composites for spall-liner application. Def Technol 12(1):52–8

Khalil HPSA, Bhat IUH, Jawaid M, Zaidon A, Hermawan D, Hadi YS (2012) Bamboo fibre reinforced biocomposites: a review. Mater Des 42:353–68

Ashik KP, Sharma RS, Guptha VLJ (2018) Investigation of moisture absorption and mechanical properties of natural/glass fiber reinforced polymer hybrid composites. Mater Today Proc 5(1):3000–7

Munirah Abdullah N, Ahmad I (2012) Effect of chemical treatment on mechanical and water-sorption properties of coconut fiber-unsaturated polyester from recycled PET. ISRN Mater Sci 2012:1–8

Okafor KJ, Edelugo SO, Ike-eze ICE, Chukwunwike SA (2021) Effect of soaking temperature on the tensile fibre-reinforced polyester composite. Polym Bull 78(9):5243–54

Muhammad A, Rahman R, Hamdan S (2019) Recent developments in bamboo fiber-based composites: a review. Polym Bull 76(5):2655–82

Yan L, Chouw N, Huang L, Kasal B (2016) Effect of alkali treatment on microstructure and mechanical properties of coir fibres, coir fibre reinforced-polymer composites and reinforced-cementitious composites. Constr Build Mater 112:168–82

Haameem M, Abdul Majid MS, Afendi M, Marzuki HFA, Hilmi EA, Fahmi I et al (2016) Effects of water absorption on Napier grass fibre/polyester composites. Compos Struct 144:138–46

Sawpan MA, Pickering KL, Fernyhough A (2011) Composites: part A effect of various chemical treatments on the fibre structure and tensile properties of industrial hemp fibres. Compos Part A 42(8):888–95

Robertson NLM, Nychka JA, Alemaskin K, Wolodko JD (2013) Mechanical performance and moisture absorption of various natural fiber reinforced thermoplastic composites. J Appl Polym Sci 130(2):969–80

Sreekala MS, Thomas S (2003) Effect of fibre surface modification on water-sorption characteristics of oil palm fibres. Compos Sci Technol 63(6):861–9

Gopalan, R;Rao, R;Murthy M, (1986) Diffusion studies on advanced fibre hybrid composites. Reinf Plast Compos 5:51–61

Giridhar J, Kishore RRMVGK (1986) moisture absorption characteristics of natural fibre composites. J Reinf Plast Compos 5(2):141–50

Venkatachalam N, Navaneethakrishnan P, Rajsekar R, Shankar S (2016) Effect of pretreatment methods on properties of natural fiber composites: a review. Polym Polym Compos 24(7):555–66

Dhakal HN, Zhang ZY, Guthrie R, MacMullen J, Bennett N (2013) Development of flax/carbon fibre hybrid composites for enhanced properties. Carbohydr Polym 96(1):1–8

Dhakal HN, Zhang ZA, Richardson MO (2007) Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos Sci Technol 67(7–8):1674–1683

Väisänen T, Das O, Tomppo L (2017) A review on new bio-based constituents for natural fiber-polymer composites. J Clean Prod 149:582–96

Fuentes CA, Tran LQN, Dupont-Gillain C, Vanderlinden W, De Feyter S, Van Vuure AW et al (2011) Wetting behaviour and surface properties of technical bamboo fibres. Coll Surf A Physicochem Eng Asp 380(1–3):89–99

Tran LQN, Fuentes CA, Dupont-Gillain C, Van Vuure AW, Verpoest I (2013) Understanding the interfacial compatibility and adhesion of natural coir fibre thermoplastic composites. Compos Sci Technol 80:23–30

Yuan Y, Lee TR (2013) Contact angle and wetting properties. Surface science techniques. Springer, Berlin, Heidelberg, pp 3–34

Akindoyo JO, Hossen Beg MD, Ghazali S, Islam MR (2016) The effects of wettability, shear strength, and Weibull characteristics of fiber-reinforced poly(lactic acid) composites. J Polym Eng 36(5):489–97

Chini SF, Amirfazli A (2011) A method for measuring contact angle of asymmetric and symmetric drops. Coll Surf A Physicochem Eng Asp 388(1–3):29–37

Bakri B, Chandrabakty S, Soe R (2016) Mechanical properties of coir rope-glass fibers reinforced polymer hybrid composites. Int J Smart Mater Mechatronics 2(2):132–5

Park JM, Quang ST, Hwang BS, DeVries K (2006) Interfacial evaluation of modified Jute and Hemp fibers/polypropylene (PP)-maleic anhydride polypropylene copolymers (PP-MAPP) composites using micromechanical technique and nondestructive acoustic emission. Compos Sci Technol 66(15):2686–99

Orue A, Jauregi A, Peña-Rodriguez C, Labidi J, Eceiza A, Arbelaiz A (2015) The effect of surface modifications on sisal fiber properties and sisal/poly (lactic acid) interface adhesion. Compos Part B Eng 73:132–8

Barsberg S, Thygesen LG (2001) Nonequilibrium phenomena influencing the wetting behavior of plant fibers. J Coll Interface Sci 234(1):59–67

Young R (1976) Wettability of wood pulp fibers: applicability of methodology. Wood Fiber Sci 8(2):120–8

Maximova N, Österberg M, Laine J, Stenius P (2004) The wetting properties and morphology of lignin adsorbed on cellulose fibres and mica. Coll Surf A Physicochem Eng Asp 239(1–3):65–75

Laschimke R (1989) Investigation of the wetting behaviour of natural lignin-a contribution to the cohesion theory of water transport in plants. Thermochim Acta 151:35–56

Tran LQN, Fuentes CA, Dupont-Gillain C, Van VuureVerpoest AWI (2011) Wetting analysis and surface characterisation of coir fibres used as reinforcement for composites. Coll Surf A Physicochem Eng Asp 377(1–3):251–60

Acknowledgements

The authors acknowledge the polishing and optical departments of the University of Birmingham, the UK and their supervisors where the polishing and optical microstructures of coir fibre were carried out.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have non-financial interest to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Madueke, C.I., Mbah, O.M. & Umunakwe, R. A review on the limitations of natural fibres and natural fibre composites with emphasis on tensile strength using coir as a case study. Polym. Bull. 80, 3489–3506 (2023). https://doi.org/10.1007/s00289-022-04241-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04241-y