Abstract

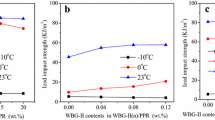

This work presents an effective approach to improve the impact toughness of isotactic polypropylene (iPP) with the addition of elastomer and maintain the stiffness of materials simultaneously, using star-shaped styrene-ethylene-butylene-styrene block copolymer (SEBS) as toughening additive and combining with annealing treatment. It was found that star-shaped SEBS has β nucleation ability on iPP. The increase in both the nucleation rate and crystal growth rate brings about the elevation of overall crystallization rate of iPP with the addition of SEBS. Characterization of the changes in microstructure and mechanical properties of pure iPP and iPP/SEBS blend upon annealing reveals that the introduction of star-shaped SEBS and further annealing treatment at moderate temperature (120–140 °C) demonstrate pronounced synergistic toughening effect on iPP. The iPP with the addition of 15 wt% SEBS has obtained impact strength of 12.8 kJ m−2, 198% higher than that of pure iPP. After annealed at 130 °C for 3 h, the impact strength of iPP alone is 72% higher than that of unannealed iPP, while this value is increased remarkably by 605% for the iPP/SEBS blend. The perfection of crystalline structure and enhanced mobility of chain segments in the amorphous region and consequent microvoids are mainly responsible for the improved toughness of iPP without serious sacrifice of modulus and stiffness realizing by the introduction of star-shaped SEBS elastomer and further annealing treatment.

Similar content being viewed by others

References

Dasari A, Zhang QX, Yu ZZ, Mai YW (2010) Toughening polypropylene and its nanocomposites with submicrometer voids. Macromolecules 43:5734–5739

Geng C, Su J, Han S, Wang K, Fu Q (2013) Hierarchical structure and unique impact behavior of polypropylene/ethylene-octene copolymer blends as obtained via dynamic packing injection molding. Polymer 54:3392–3401

Xu J, Mittal V, Bates FS (2016) Toughened isotactic polypropylene: phase behavior and mechanical properties of blends with strategically designed random copolymer modifiers. Macromolecules 49:6497–6506

Hristov V, Lach R, Krumova M, Grellmann W (2005) Fracture toughness of modified polypropylene/poly (styrene-ran-butadiene) blends. Polym Int 54:1632–1640

Grein C, Gahleitner M (2008) On the influence of nucleation on the toughness of iPP/EPR blends with different rubber molecular architectures. Express Polym Lett 2:392–397

Shangguan Y, Chen F, Yang J, Jia E, Zheng Q (2017) A new approach to fabricate polypropylene alloy with excellent low-temperature toughness and balanced toughness-rigidity through unmatched thermal expansion coefficients between components. Polymer 112:318–324

Jia E, Shangguan Y, Xiong J, Chen F, Zheng Q (2018) Fabrication of polypropylene blends with excellent low-temperature toughness and balanced toughness-rigidity by a combination of EPR and SEEPS. J Appl Polym Sci 135:45714

Sun DX, Lei YZ, Lu Y, Cao S, Qi XD, Wang Y (2020) Fabrication of super-toughened polypropylene-based nanocomposite with low elastomer content through tailoring the microscale damage mechanisms. Compos Sci Technol 193:108148

Zhao S, Shangguan Y, Wu Q, Li Z, Zheng Q (2021) Toughening mechanism of PP/EPR/SiO2 composites with superior low-temperature toughness. Compos Sci Technol 207:108691

Su Z, Dong M, Guo Z, Yu J (2007) Study of polystyrene and acrylonitrile-styrene copolymer as special β-nucleating agents to induce the crystallization of isotactic polypropylene. Macromolecules 40:4217–4224

Zhang Z, Wang C, Yang Z, Chen C, Mai K (2008) Crystallization behavior and melting characteristics of PP nucleated by a novel supported β-nucleating agent. Polymer 49:5137–5145

Yi QF, Wen XJ, Dong JY, Han CC (2008) A novel effective way of comprising a β-nucleating agent in isotactic polypropylene (i-PP): polymerized dispersion and polymer characterization. Polymer 49:5053–5063

Luo F, Geng C, Wang K, Deng H, Chen F, Fu Q, Na B (2009) New understanding in tuning toughness of β-polypropylene: the role of β-nucleated crystalline morphology. Macromolecules 42:9325–9331

Zhang Y, Zhang L, Liu H, Du H, Zhang J, Wang T, Zhang X (2013) Novel approach to tune mechanics of β-nucleation agent nucleated polypropylene: Role of oriented β spherulite. Polymer 54:6026–6035

Kang J, Weng G, Chen Z, Chen J, Cao Y, Yang F, Xiang M (2014) New understanding in the influence of melt structure and β-nucleating agents on the polymorphic behavior of isotactic polypropylene. RSC Adv 4:29514–29526

Kersch M, Schmidt HW, Altstädt V (2016) Influence of different beta-nucleating agents on the morphology of isotactic polypropylene and their toughening effectiveness. Polymer 98:320–326

Yang R, Ding L, Chen W, Chen L, Zhang X, Li J (2017) Chain folding in main-chain liquid crystalline polyester with strong π–π interaction: An efficient β-nucleating agent for isotactic polypropylene. Macromolecules 50:1610–1617

Yue Y, Hu D, Zhang Q, Lin J, Feng J (2018) The effect of structure evolution upon heat treatment on the beta-nucleating ability of calcium pimelate in isotactic polypropylene. Polymer 149:55–64

Qin W, Xin Z, Pan C, Sun S, Jiang X, Zhao S (2019) In situ formation of zinc phthalate as a highly dispersed β-nucleating agent for mechanically strengthened isotactic polypropylene. Chem Eng J 358:1243–1252

Wang Z (1996) Toughening and reinforcing of polypropylene. J Appl Polym Sci 60:2239–2243

Champagne MF, Huneault MA, Roux C, Peyrel W (1999) Reactive compatibilization of polypropylene/polyethylene terephthalate blends. Polym Eng Sci 39:976–984

Tseng FP, Lin JJ, Tseng CR, Chang FC (2001) Poly (oxypropylene)-amide grafted polypropylene as novel compatibilizer for PP and PA6 blends. Polymer 42:713–725

Duvall J, Sellitti C, Myers C, Hiltner A, Baer E (1994) Effect of compatibilization on the properties of polypropylene/polyamide-66 (75/25 wt/wt) blends. J Appl Polym Sci 52:195–206

Wang K, Wu J, Zeng H (2006) Microstructure and fracture behavior of polypropylene/barium sulfate composites. J Appl Polym Sci 99:1207–1213

Lin Y, Chen H, Chan CM, Wu J (2008) High impact toughness polypropylene/CaCO3 nanocomposites and the toughening mechanism. Macromolecules 41:9204–9213

Liu JR, Li C, Hu FM (2018) Effect of polystyrenes with different architectures on the β-nucleating efficiency and toughening of isotactic polypropylene. Polym Int 67:506–514

Liu JR, Zhu XX (2019) Isotactic polypropylene toughened with poly (acrylonitrile-butadiene-styrene): compatibilizing role of maleic anhydride grafted polypropylene. Polym Eng Sci 52:E317-326

Liu JR, Zhu XX (2019) Isotactic polypropylene toughened with poly (acrylonitrile-butadiene-styrene): compatibilizing role of nano-ZnO. Polym Plast Technol Mater 58:2007–2018

Liu JR, Zhang LC, Fang Z (2021) Well dispersion of poly (acrylonitrile-butadiene-styrene) in isotactic polypropylene mediated by incorporation of graphene and the elevated toughness. Polym Adv Technol 32:2020–2029

Ghosh S, Bhowmick AK, Roychowdhury N, Holden G (2000) Influence of block molecular weight on the properties of styrene-ethylene-butylene-styrene block copolymers. J Appl Polym Sci 77:1621–1628

Zhou T, Zhang A, Zhao C, Liang H, Wu Z, Xia J (2007) Molecular chain movements and transitions of SEBS above room temperature studied by moving-window two-dimensional correlation infrared spectroscopy. Macromolecules 40:9009–9017

Arevalillo A, Muñoz ME, Calafell I, Santamaría A, Fraga L, Barrio JA (2012) Thermo-mechanical properties linked to rheological features in high molecular weight SEBS copolymers: effect of styrene content and ethylene/butylene proportion. Polym test 31:849–854

Liu JR, Shen K, Yu Q (2017) Changes of surface morphology of star-like SEBS block copolymers aggregate studied by atomic force microscopy. Fine Chem 34:121–127

Liu JR, Zhu TC (2021) Effect of entanglement upon branching on dispersibility, β-nucleating and mechanically strengthening ability of polystyrene in isotactic polypropylene. Polym Bull 78:3259–3274

Liu JR, Zhu XX, Cao Z (2019) Poly(acrylonitrile–butadiene–styrene) as a special β-nucleating agent on the toughness of isotactic polypropylene. Polymers 11:1894

Liu JR, Liang HW, Li C, Hu FM (2019) Study of phenyl-terminated hyperbranched polyester as a special β-nucleating agent on the toughness of isotactic polypropylene. Polym Eng Sci 52:E133-143

Bai H, Wang Y, Zhang Z, Han L, Li Y, Liu L, Zhou Z, Men Y (2009) Influence of annealing on microstructure and mechanical properties of isotactic polypropylene with β-phase nucleating agent. Macromolecules 42:6647–6655

Bai H, Luo F, Zhou T, Deng H, Wang K, Fu Q (2011) New insight on the annealing induced microstructural changes and their roles in the toughening of β-form polypropylene. Polymer 52:2351–2360

Han L, Li X, Li Y, Huang T, Wang Y, Wu J, Xiang F (2010) Influence of annealing on microstructure and physical properties of isotactic polypropylene/calcium carbonate composites with β-phase nucleating agent. Mater Sci Eng A 527:3176–3185

Li X, Wu H, Han L, Huang T, Wang Y, Bai H, Zhou Z (2010) Annealing induced microstructure and fracture resistance changes in isotactic polypropylene/ethylene-octene copolymer blends with and without β-phase nucleating agent. J Polym Sci Part B Polym Phys 48:2108–2120

Wu H, Li X, Wang Y, Wu J, Huang T, Wang Y (2011) Fracture behaviors of isotactic polypropylene/poly (ethylene oxide) blends: effect of annealing. Mater Sci Eng A 528:8013–8020

Lin Y, Chen H, Chan CM, Wu J (2012) Annealing-induced high impact toughness of polypropylene/CaCO3 nanocomposites. J Appl Polym Sci 124:77–86

Hedesiu C, Demco DE, Kleppinger R, Poel GV, Gijsbers W, Blümich B, Remerie K, Litvinov VM (2007) Effect of temperature and annealing on the phase composition, molecular mobility and the thickness of domains in isotactic polypropylene studied by proton solid-state NMR, SAXS and DSC. Macromolecules 40:3977–3989

Na B, Li Z, Lv R, Zou S (2012) Annealing-induced structural rearrangement and its toughening effect in injection-molded isotactic polypropylene. Polym Eng Sci 52:893–900

Zhou X, Feng J, Yi J, Wang L (2013) Synergistic improvement of toughness of isotactic polypropylene: the introduction of high density polyethylene and annealing treatment. Mater Des 49:502–510

Chen JW, Dai J, Yang JH, Zhang N, Huang T, Wang Y, Zhang CL (2014) Amplified toughening effect of annealing on isotactic polypropylene realized by introducing microvoids. Ind Eng Chem Res 53:4679–4688

Chen JW, Dai J, Yang JH, Zhang N, Huang T, Wang Y, Zhang CL (2015) Annealing induced microstructure and mechanical property changes of impact resistant polypropylene copolymer. Chin J Polym Sci 33:1211–1224

Pan Y, Liu X, Shi S, Liu C, Dai K, Yin R, Schubert DW, Zheng G, Shen C (2016) Annealing induced mechanical reinforcement of injection molded iPP parts. Macromol Mater Eng 301:1468–1472

Ravi S, Takahashi K (2002) Toughening mechanisms in annealed high density polyethylene under impact. Polym Eng Sci 42:2146–2155

Ferrer-Balas D, Maspoch ML, Martinez AB, Santana OO (2001) Influence of annealing on the microstructural, tensile and fracture properties of polypropylene films. Polymer 42:1697–1705

Li JX, Cheung WL, Jia D (1999) A study on the heat of fusion of β-polypropylene. Polymer 40:1219–1222

Bai H, Wang Y, Song B, Li Y, Liu L (2008) Detecting crystallization structure evolution of polypropylene injection-molded bar induced by nucleating agent. Polym Eng Sci 48:1532–1541

Yalcin B, Cakmak M (2004) Superstructural hierarchy developed in coupled high shear/high thermal gradient conditions of injection molding in nylon 6 nanocomposites. Polymer 45:2691–2710

Jones AT, Aizlewood JM, Beckett DR (1964) Crystalline forms of isotactic polypropylene. Die Makromol Chem 75:134–158

Yang R, Ding L, Zhang X, Li J (2018) Nonisothermal crystallization, melting behaviors, and mechanical properties of isotactic polypropylene nucleated with a liquid crystalline polymer. Ind Eng Chem Res 57:2083–2093

Kissinger HE (1956) Variation of peak temperature with heating rate in differential thermal analysis. J Res Natl Bur Stand 57:217–221

Mendienta-García MB, Páramo-García U, Díaz-Zavala NP, Robledo-Muñiz JG, Rivera-Armenta JL (2013) Thermal & morphological evaluation of linear and radial SEBS-polypropylene blends. Polímeros 23:597–601

Gupta AK, Purwar SN (1984) Crystallization of PP in PP/SEBS blends and its correlation with tensile properties. J Appl Polym Sci 29:1595–1609

Fanegas N, Gómez MA, Marco C, Jiménez I, Ellis G (2007) Influence of a nucleating agent on the crystallization behaviour of isotactic polypropylene and elastomer blends. Polymer 48:5324–5331

Setz S, Stricker F, Kressler J, Duschek T, Mülhaupt R (1996) Morphology and mechanical properties of blends of isotactic or syndiotactic polypropylene with SEBS block copolymers. J Appl Polym Sci 59:1117–1128

Abreu F, Forte MMC, Liberman SA (2005) SBS and SEBS block copolymers as impact modifiers for polypropylene compounds. J Appl Polym Sci 95:254–263

Aboulfaraj M, G’sell C, Ulrich B, Dahoun A (1995) In situ observation of the plastic deformation of polypropylene spherulites under uniaxial tension and simple shear in the scanning electron microscope. Polymer 36:731–742

Coulon G, Castelein G, G’sell C (1999) Scanning force microscopic investigation of plasticity and damage mechanisms in polypropylene spherulites under simple shear. Polymer 40:95–110

Tordjeman P, Robert C, Marin G, Gerard P (2001) The effect of α, β crystalline structure on the mechanical properties of polypropylene. Eur Phys J E 4:459–465

Zia Q, Mileva D, Androsch R (2008) Rigid amorphous fraction in isotactic polypropylene. Macromolecules 41:8095–8102

Hedesiu C, Demco DE, Kleppinger R, Poel GV, Remerie K, Litvinov VM, Blumich B, Steenbakkers R (2008) Aging effects on the phase composition and chain mobility of isotactic poly (propylene). Macromol Mater Eng 293:847–857

Varga J (2002) β-modification of isotactic polypropylene: preparation, structure, processing, properties and application. J Polym Sci Part B Polym Phys 41:1121–1171

Labour T, Gauthier C, Seguela R, Vigier G, Bomal Y, Orange G (2001) Influence of the β crystalline phase on the mechanical properties of unfilled and CaCO3-filled polypropylene I structural and mechanical characterisation. Polymer 42:7127–7135

Labour T, Vigier G, Séguéla R, Gauthier C, Orange G, Bomal Y (2002) Influence of the β-crystalline phase on the mechanical properties of unfilled and calcium carbonate-filled polypropylene: ductile cracking and impact behavior. J Polym Sci Part B Polym Phys 40:31–42

Boyd RH (1985) Relaxation processes in crystalline polymers: experimental behaviour—a review. Polymer 26:323–347

Read BE (1989) Mechanical relaxation in isotactic polypropylene. Polymer 30:1439–1445

Zhang X, Sun B, Yuan G, Zhang S, Ji Y, Liu B, Zhang M, Yang Y, Chen J (2021) Preparation and balanced mechanical properties of solid and foamed isotactic polypropylene/SEBS composites. J Appl Polym Sci 138:50342

Chen Y, Wu Z, Fan Q, Yang S, Song E, Zhang Q (2018) Great toughness reinforcement of isotactic polypropylene/elastomer blends with quasi-cocontinuous phase morphology by traces of β-nucleating agents and carbon nanotubes. Compos Sci Technol 167:277–284

Pawlak A, Galeski A (2008) Cavitation during tensile deformation of polypropylene. Macromolecules 41:2839–2851

Bajpai A, Wetzel B (2019) Effect of different types of block copolymers on morphology, mechanical properties and fracture mechanisms of bisphenol-F based epoxy system. J Compos Sci 3:68

Klingler A, Bajpai A, Wetzel B (2018) The effect of block copolymer and core-shell rubber hybrid toughening on morphology and fracture of epoxy-based fibre reinforced composites. Eng Fract Mech 203:81–101

Acknowledgements

This work was financially supported by the project funded by the Priority Academic Program Development (PAPD) of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, J., Guo, D. Remarkably improved toughness of isotactic polypropylene realized by introducing star-shaped SEBS and annealing treatment. Polym. Bull. 80, 2985–3003 (2023). https://doi.org/10.1007/s00289-022-04208-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04208-z