Abstract

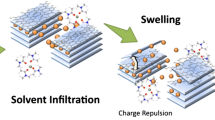

The ternary phase diagram based on cellulose (cellulose polymer/mixed solvents/Water (non-solvent)) system has been measured at 30 °C for two sources of cellulose. Cellulose synthesized from fibers of cotton and olive significantly influences the behavior of the crystallization index, which can cause changes during the film formation process. The differences can be explained by the presence of amorphous areas linked to a higher disorder, which is highlighted by the X-ray diffraction analysis XRD (crystallinity rate was 15.6% versus 47.4% for acetylated cellulose). The experimental analysis was carried out on the coexisting phases and the determination of binodal curve. The cellulose film was formed based on the equilibrium diagram to control the structure, which showed some dependence between the composition data and the binary interaction parameters in order to achieve liquid–liquid phase separation. This system required a large amount of water (15–90 wt.% water) to affect the porous and fibrous structure of the film. Olive cellulose films with lower crystallinity have smaller diameter (38 nm), they can swells faster and their solubility increases more, unlike acetate cellulose (56 nm). It can be said that the solvent diffusion is greater in the amorphous domains due to their higher disorder resulting in easy accessibility.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

Change history

18 May 2022

A Correction to this paper has been published: https://doi.org/10.1007/s00289-022-04273-4

References

Salgado PR, Schmidt VC, Molina Ortiz SE, Mauri AN, Laurindo JB (2008) Biodegradable foams based on cassava starch, sunflower proteins and cellulose fibers obtained by a baking process. J Food Eng. 85:435–443

Hsissou R, Seghiri R, Benzekri Z, Hilali M, Rafik M, Elharfi A (2021) Polymer composite materials: a comprehensive review. Compos Struct 262:113640

De Conto D, dos Santos V, Zattera AJ et al (2021) Swelling of biodegradable polymers for the production of nanocapsules and films with the incorporation of essential oils. Polym Bull 78:7261–7278

Hsissou R, Berradi M, El Bouchti M et al (2019) Synthesis characterization rheological and morphological study of a new epoxy resin pentaglycidyl ether pentaphenoxy of phosphorus and their composite (PGEPPP/MDA/PN). Polymer Bull 76:4859–4878

Satyanarayana KG, Arizaga GGC, Wypych F (2009) Biodegradable composites based on lignocellulosic fibers—an overview. Prog Polym Sci 34:982–1021

Liu W, Misra M, Askeland P, Drzal LT, Mohanty AK (2005) Green composites from soy based plastic and pineapple leaf fiber: fabrication and properties evaluation”. Polymer 46:2710–2721

Wu RL, Wang XL, Li F, Li HZ, Wang YZ (2009) Green composite films prepared from cellulose, starch and lignin in room-temperature ionic liquid”. Biores Technol 100:2569–2574

Altena FW, Smolders C (1982) Calculation of liquid-liquid phase separation in a ternary system of a polymer in a mixture of a solvent and a nonsolvent. Macromolecules 15:1493–1497

Chunsheng S, Mengjie B, Honghui X, Yong D, Shequan W, Guanghua W (2011) A thermodynamic modeling of the C-Cr–Ta ternary system. J Alloy Compd 509:5996–6003

John E, Tanja E, Thomas R, Hartmut R, Herbert S et al (2009) Phase diagram of the ternary system NMMO/water/cellulose. Cellulose 16:373–379

Frank WA, Smolders CA (1982) Calculation of Liquid-Liquid Phase Separation in a Ternary System of a Polymer in a Mixture of a Solvent and a Nonsolvent. Macromolecules. 15:1491–1497

Machado PST, Habert AC, Borges CP (1999) Film formation mechanism based on precipitation kinetics and film morphology: flat and hollow fiber polysulfone films. J Membr Sci 155:171–183

Gonzalez-Leon JA, Mayes AM (2003) Phase behavior prediction of ternary polymer mixtures. Macromolecules 36:2508–2515

Ebrahimpour M, Safekordi AA, Mousavi SM, Nasab AH (2016) Phase separation analysis in the ternary system of poly(butylene succinate)/1,1,2,2,-tetrachlo ethane/nonsolvent in relation to film formation. Int Bus Manag 10:5876–5884

Hindi SSZ, Abohassan RA (2015) Cellulose acetate synthesis from cellulosic wastes by heterogeneous reactions. BioResources 10:5030–5048

Cheng HN, Dowd MK, Selling GW, Biswas A (2010) Synthesis of cellulose acetate from cotton byproducts. Carbohyd Polym 80:449–452

Rinaudo M, Pavlov G, Desbrieres J (1999) Influence of acetic acid concentration on the solubilization of chitosane. Polymer 40:7029–7032

de la Casa JA, Castro E (2014) Recycling of washed olive pomace ash for fired clay brick manufacturing. Constr Build Mater 61:320–326

Moran JI, Alvarez VA, Cyras VP, Vazquez A (2007) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Springer Sci 15(1):150–151

Perez J, Munoz-Dorado J, de la Rubia T, Martínez J (2002) Biodegradation and biological treatments of cellulose, hemicellulose and lignin: an overview. Int Microbiol 5:53–63

Eckelt J, Wolf BA (2008) Thermodynamic interaction parameters for the system water/NMMO hydrate. J Phys Chem B 112:3397–3401

Koningsveld R, Stockmayer WH, Nies E (2001) Polymer phase diagrams. Oxford University Press Inc, New York

Wolf BA (2009) Binary interaction parameters, ternary systems: realistic modeling of liquid/liquid phase separation. Macromol Theory Simul 18:30–41

Basiak E, Lenart A, Debeaufort F (2018) How Glycerol and Water Contents Affect the Structural and Functional Properties of Starch-Based Edible Films. Polymers 10(4):412

Arpi N, Fahrizal M, Hardianti E (2018) Preparation and characterization of biodegradable film based on skin and bone fish gelatin. IOP Conf Ser: Earth Environ Sci 207:012050. https://doi.org/10.1088/1755-1315/207/1/012050

Yanrong Liu Y, Nie FP, Zhou L, Ji X, Kang Z, Zhang S (2019) Study on ionic liquid/cellulose/coagulator phase diagram and its application in green spinning process. J. Molec. Liq. 289:111127

Ioelovich MY, Veveris GP (1987) Determination of cellulose crystallinity by X-ray diffraction method. J Wood Chem 5:72–80

Rbihi S, el hallani G, Jouaiti A et al (2021) Influence of cellulose on the thermal conductivity of cellulose based composite thin films. Thermal Sci Eng Progr. https://doi.org/10.1016/j.tsep.2020.100790

Rodríguez FJ, Coloma A, Galotto MJ, Guarda A, Bruna JE (2012) Effect of organoclay content and molecular weight on cellulose acetate nanocomposites properties. Polym Degrad Stab 97:1996–2001

Sookne AM, Harris M (1945) Intrinsic viscosities and osmotic molecular weights of cellulose acetate fractions. J Res Nat Bureau Stan. https://doi.org/10.6028/jres.034.026

Tolbert A, Akinosho H, Khunsupat R et al (2014) Characterization and analysis of the molecular weight of lignin for biorefining studies. Biofuels, Bioproducts and Biorefining

Acknowledgements

The authors are grateful to the center of analysis and quality control (AQC) of Moulay Slimane University for characterization support.

Funding

No funds or other support was received from any organization for the submitted work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rbih, S., Neggaoui, H., Laallam, L. et al. Study on the ternary phase diagram of synthesized cellulose/mixed solvents/water system: influence of crystallinity on dissolution. Polym. Bull. 80, 917–928 (2023). https://doi.org/10.1007/s00289-022-04108-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04108-2