Abstract

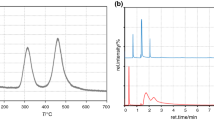

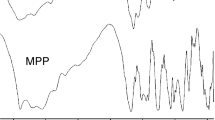

Polypropylene (PP) is one of the most widely used commodity plastic materials worldwide in terms of the production and its consumption. At commercial scale, PP is produced in various grades like homopolymer and copolymer (random and impact) by the polymerization of propylene and mixture of propylene-ethylene monomers using Ziegler–Natta catalysts and alkyl aluminum as co-catalysts. The present study deals with the colored lump formation of polypropylene random copolymer (PPCP) during storage at large scale and its probable route cause analysis for the lump formation. The lump samples were collected and characterized using FTIR, TGA, DSC and molecular weight determination and compared with pure PPCP. FTIR data show all the signature peaks of PPCP with additional > C=O stretching near 1720 cm−1 in colored lump sample, TG analysis revealed degradation of PPCP polymer and formation of volatile organic compounds in the temperature range 200–250 °C, the DSC analysis of the colored lump and pure PPCP showed that the melting peak was broader for colored lump of PPCP (i.e., PPCP_Y) which is an indicative that polymer molecules were having different chain length and the molecular weight analysis showed that the colored sample was having very low molecular weight with some bimodal character as compared to pure polymer. Based on these data and observations, the possible reason for the colored lump formation was also discussed.

Graphical abstract

Similar content being viewed by others

References

García JM (2016) Catalyst: design challenges for the future of plastics recycling. Chem 1:813–815. https://doi.org/10.1016/j.chempr.2016.11.003

Mantia FL (ed) (2002) Handbook of plastics recycling. Rapra Technology, Shrewsbury

Maddah HA (2016) Polypropylene as a promising plastic: a review. Am J Polym Sci 6:1–11. https://doi.org/10.5923/j.ajps.20160601.01

Leone G, Mauri M, Pierro I, Ricci G, Canetti M, Bertini F (2016) Polyolefin thermoplastic elastomers from 1-octene chain-walking polymerization. Polymer 100:37–44. https://doi.org/10.1016/j.polymer.2016.08.009

Wang X, Hu S, Guo Y, Li G, Xu R (2019) Toughened high-flow polypropylene with polyolefin-based elastomers. Polymers 11:1976–1989

Baier MC, Zuideveld MA, Mecking S (2014) Post-metallocenes in the industrial production of polyolefins. Angew Chem Int Ed 53:2–25. https://doi.org/10.1002/anie.201400799

Wang X, Xu R, Kang W, Fan J, Han X, Xu Y (2020) Versatile Polypropylene copolymers from a pilot-scale spheripol II process. Polymers 12:751

Wang X, Han X, Xu R (2019) Versatile propylene-based polyolefins with tunable molecular structure through tailor-made catalysts and polymerization process. IntechOpen. https://doi.org/10.5772/intechopen.85963

Sato R, Ogawa H (2009) Review on development of polypropylene manufacturing process. “SUMITOMO KAGAKU”, Vol II, Sumitomo Chemical Co. Ltd.

Khan MJH, Hussain MA, Mujtaba IM (2014) Polypropylene production optimization in fluidized bed catalytic reactor (FBCR): statistical modeling and pilot scale experimental validation. Materials 7:2440–2458. https://doi.org/10.3390/ma7042440

Giacco AF (1987) Himont aims to remain polypropylene leader. Chem Eng News 65:7–8

Cesaroni F (2003) Technology strategies in the knowledge economy: the licensing activity of himont. Int J Innov Management 7:223–245

Takada H, Karapanagioti HK (2017) Hazardous chemicals associated with plastics in the marine environment. Hdb Env Chem. https://doi.org/10.1007/698_2017_11

Pospisil J, Habicher WD, Pilar J, Nespurek S, Kuthan J, Piringer GO, Zweifel H (2002) Discoloration of polymers by phenolic antioxidants. Polym Degrad Stab 77:531–538

Skaare LE, Kiaeboe P, Nielsen CJ, Gundersen G (1992) Spectroscopic studies of ethylene-propylene copolymers in the near- and mid-infrared regions. Vibra Spec 3:23–33

Ng HM, Saidi NM, Kasi R, Subramaniam RT (2018) Encyclopaedia of polymer science and technology. Wiley

Carraher CE Jr (2017) Introduction to polymer chemistry, 4th edn. CRC Press, Taylor and Francis group

Ando I, Asakura T (1998) Chapter 11, Solid state NMR of polymers, studies in physical and theoretical chemistry, Elsevier

Bunn A, Cudby MEA, Harris RK, Packer KJ, Say BJ (1982) High resolution 13C n.m.r. spectra of solid isotactic polypropylene. Polymer 23:694

Natta G, Corradini C (1960) Structure and properties of isotactic polypropylene. Nouvo Cim Suppl 15:40

Grant DM, Cheney BV (1967) Carbon-13 magnetic resonance: VII—Steric perturbation of the carbon-13 chemical shift. J Am Chem Soc 89:5315

Shibryaeva L (2012) Book CHAPTER, IntechOpen, Polypropylene, Dr. Fatih Dogan (Ed.), ISBN: 978-953-51-0636-4

Gomez MA, Tanaka H, Tonelli AE (1987) High-resolution solid-state 13C nuclear magnetic resonance study of isotactic polypropylene polymorphs. Polymer 28:2227

Wanasekara N, Chalivendra V, Calvert P (2011) Sub-micron scale mechanical properties of polypropylene fibers exposed to ultraviolet and thermal degradation. Polym Degrad Stab 96:432–437

Yano A, Akai N, Ishii N, Satoh C, Hironiwa T, Millington KR, Nakata M (2013) Thermal oxidative degradation of additive-free polypropylene pellets investigated by multichannel Fourier-transform chemiluminescence spectroscopy. Polym Degrad Stab 98:2680–2686

Epacher E, Kröhnke C, Pukánszky B (2000) Effect of catalyst residues on the chain structure and properties of a Phillips type polyethylene. Polym Eng Sci 40:1458–1468

Acknowledgements

The authors would like to thank M/s Reliance Industries Limited, Mumbai, for giving permission to publish this paper. Analytical support provided by the central analytical team at Reliance Research and development Centre, Reliance Industries Limited, Mumbai.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tripathi, S.N., Shukla, D.K., Bonda, S. et al. Investigation of colored lump formation inside the silos during the production of polypropylene copolymer. Polym. Bull. 79, 11285–11299 (2022). https://doi.org/10.1007/s00289-022-04090-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04090-9