Abstract

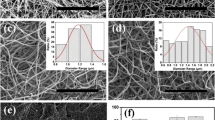

Hybrid polymers have been used as biomaterials for tissue engineering recently. In this study, the hybrid fibrous scaffolds of polycaprolactone (PCL), gelatin (G) and polydimethylsiloxane (PDMS) with two various types of fiber arrangement were fabricated with different mass ratio by electrospinning. Physicochemical properties of fabricated scaffolds were evaluated using scanning electron microscopy, the immersion of scaffold samples, attenuated total reflectance Fourier transform infrared, X-ray diffraction and tensile strength analysis. Cytotoxicity analyses of scaffolds and human foreskin fibroblasts on the scaffolds were assessed by 3-(4, 5-dimethylthiazoyl-2-yl) 2, 5-diphenyltetrazolium bromide assay. Attachment to the scaffolds and morphology of fibroblasts on them were evaluated by hematoxylin–eosin staining and scanning electron microscopy. Networks and nanofibers less than 30 nm were created throughout the normal nanofibers of PCL/G/PDMS hybrid scaffolds that the efficiency of the homing and proliferation of the fibroblasts cells onto the scaffolds was improved. The PCL/G/PDMS hybrid scaffolds characteristics, especially morphology, mechanical properties and biocompatibility by altering the ratio PCL, G and PDMS show that these scaffolds are suitable for random and aligned tissue engineering applications, especially engineering of elastic tissues (nerve, uterus, bladder, trachea, heart valves, vein, vagina, liver, skin and others).

Similar content being viewed by others

References

Dhandayuthapani B, Yoshida Y, Maekawa T, Kumar DS (2011) Polymeric scaffolds in tissue engineering application: a review. Int J Polym Sci 2011:1–19

Habibi N, Kamaly N, Memic A, Shafiee H (2016) Self-assembled peptide-based nanostructures: smart nanomaterials toward targeted drug delivery. Nano Today 11:41–60

Wang P, Zhao L, Liu J, Weir MD, Zhou X, Xu HHK (2014) Bone tissue engineering via nanostructured calcium phosphate biomaterials and stem cells. Bone Res 2:14017

Armentano I, Bitinis N, Fortunati E, Mattioli S, Rescignano N, Verdejo R, Lopez-Manchado MA, Kenny JM (2013) Multifunctional nanostructured PLA materials for packaging and tissue engineering. Prog Polym Sci 38:1720–1747

Li X, Wang L, Fan Y, Feng Q, Cui F-Z, Watari FJ (2013) Nanostructured scaffolds for bone tissue engineering. Biomed Mater Res A 101A:2424–2435

Piskin E (1995) Biodegradable polymers as biomaterials. J Biomater Sci Polym Ed 6:775–795

Ji Y, Ghosh K, Zheng Shu X, Li B, Sokolov JC, Prestwich GD, Clark RAF, Rafailovich MH (2006) Electrospun three-dimensional hyaluronic acid nanofibrous scaffolds. Biomaterials 27:3782–3792

Coenen AMJ, Bernaerts KV, Harings JAW, Jockenhoevel S, Ghazanfari S (2018) Elastic materials for tissue engineering applications: natural, synthetic, and hybrid polymers. Acta Biomater 79:60–82

Hajiali F, Tajbakhsh S, Shojaei A (2018) Fabrication and properties of polycaprolactone composites containing calcium phosphate-based ceramics and bioactive glasses in bone tissue engineering: a review. Polym Rev 58:164–207

Hench LL (1991) Bioceramics: from concept to clinic. J Am Ceram Soc 74:1487–1510

CSIRO Molecular Science, Bag 10, Clayton South MDC, Vic 3169, Australia and Gunatillake P (2003) Eur Cell Mater 5:1–16

Bhat S, Chen C, Day DA (2013) Effects of a polycaprolactone (PCL) tissue scaffold in Rattus norvegicus on blood flow. MRS Proc 1498:27–31

Zhao P, Gu H, Mi H, Rao C, Fu J, Turng L (2018) Fabrication of scaffolds in tissue engineering: a review. Front Mech Eng 13:107–119

Jammalamadaka U, Tappa K (2018) Recent advances in biomaterials for 3D printing and tissue engineering. J Funct Biomater 9:22

Heydari Z, Mohebbi-Kalhori D, Afarani MS (2017) Engineered electrospun polycaprolactone (PCL)/octacalcium phosphate (OCP) scaffold for bone tissue engineering. Mater Sci Eng C 81:127–132

Kundu J, Shim J-H, Jang J, Kim S-W, Cho D-W (2015) An additive manufacturing-based PCL-alginate-chondrocyte bioprinted scaffold for cartilage tissue engineering. J Tissue Eng Regen Med 9:1286–1297

Zhang YZ, Venugopal J, Huang Z-M, Lim CT (2005) Characterization of the surface biocompatibility of the electrospun PCL-collagen nanofibers using fibroblasts. Biomacromolecules 6:2583–2589

Rajzer I, Rom M, Menaszek E, Pasierb P (2015) Conductive PANI patterns on electrospun PCL/gelatin scaffolds modified with bioactive particles for bone tissue engineering. Mater Lett 138:60–63

Chong EJ, Phan TT, Lim IJ, Zhang YZ, Bay BH, Ramakrishna S, Lim CT (2007) Evaluation of electrospun PCL/gelatin nanofibrous scaffold for wound healing and layered dermal reconstitution. Acta Biomater 3:321–330

Jing X, Mi H-Y, Wang X-C, Peng X-F, Turng L-S (2015) Shish-kebab-structured poly(ε-caprolactone) nanofibers hierarchically decorated with chitosan–poly(ε-caprolactone) copolymers for bone tissue engineering. ACS Appl Mater Interfaces 7:6955–6965

Gomes SR, Rodrigues G, Martins GG, Roberto MA, Mafra M, Henriques CMR, Silva JC (2015) In vitro and in vivo evaluation of electrospun nanofibers of PCL, chitosan and gelatin: a comparative study. Mater Sci Eng C 46:348–358

Gautam S, Dinda AK, Mishra NC (2013) Fabrication and characterization of PCL/gelatin composite nanofibrous scaffold for tissue engineering applications by electrospinning method. Mater Sci Eng C 33:1228–1235

Mansoori S, Davarnejad R, Matsuura T (2020) Membranes based on non-synthetic (natural) polymers for wastewater treatment. Polym Test 84:106381

Courtney TH (2013) Mechanical behavior of materials. McGraw Hill Education (India), New Delhi

Rogers JA, Nuzzo RG (2005) Recent progress in soft lithography. Mater Today 8:50–56

McDonald JC, Duffy DC, Anderson JR, Chiu DT, Wu H, Schueller OJA, Whitesides GM (2000) Fabrication of microfluidic systems in poly(dimethylsiloxane). Electrophoresis 21:27–40

Wang Zh, Volinsky AA, Gallant N (2011) Polydimethylsiloxane mechanical properties measured by macroscopic compression and nanoindentation techniques. University of South Florida Scholar Commons

Nalwa HS (ed) (2003) Handbook of photochemistry and photobiology. American Scientific Publishers, Stevenson Ranch, CA

Xue J, Wu T, Dai Y, Xia Y (2019) Electrospinning and electrospun nanofibers: methods, materials, and applications. Chem Rev 119:5298–5415

Sagitha P, Reshmi CR, Sundaran SP, Sujith A (2018) Recent advances in post-modification strategies of polymeric electrospun membranes. Eur Polym 105:227–249

Pham QP, Sharma U, Mikos AG (2006) Electrospinning of polymeric nanofibers for tissue engineering applications: a review. Tissue Eng 12:1197–1211

Hasan A, Memic A, Annabi N, Hossain M, Paul A, Dokmeci MR, Dehghani F, Khademhosseini A (2014) Electrospun scaffolds for tissue engineering of vascular grafts. Acta Biomater 10:11–25

Ghasemi-Mobarakeh L, Prabhakaran MP, Morshed M, Nasr-Esfahani MH, Ramakrishna S (2008) Electrospun poly(3-caprolactone)/gelatin nanofibrous scaffolds for nerve tissue engineering. Biomaterials 29:4532–4539

Kim MS, Jun I, Shin YM, Jang W, Kim SI, Shin H (2010) The development of genipin-crosslinked poly(caprolactone) (PCL)/gelatin nanofibers for tissue engineering applications. Macromol Biosci 10:91–100

Varshney N, Sahi AK, Vajanthri KY, Poddar S, Balavigneswaran CK, Prabhakar A, Rao V, Mahto SK (2019) Culturing melanocytes and fibroblasts within three-dimensional macroporous PDMS scaffolds: towards skin dressing material. Cytotechnology 71:287–303

Kai D, Prabhakaran MP, Chan BQY, Liow SS, Ramakrishna S, Xu F, Loh XJ (2016) Elastic poly(ε-caprolactone)-polydimethylsiloxane copolymer fibers with shape memory effect for bone tissue engineering. Biomed Mater 11:015007

Dehghan M, Khajeh-Mehrizi M, Nikukar H (2020) Modeling and optimizing a polycaprolactone/gelatin/polydimethylsiloxane nanofiber scaffold for tissue engineering: using response surface methodology. J Text Inst 112:482–493

Dehghan M, Nikukar H, Khajeh-Mehrizi M (2020) Optimizing the physical parameters of polycaprolactone–gelatin–polydimethylsiloxane composite nanofibr scaffold for tissue engineering application. J Ind Text. https://doi.org/10.1177/1528083720960156

Dehghan N, Tavanaie MA, Payvandy P (2015) Morphology study of nanofibers produced by extraction from polymer blend fibers using image processing. Korean J Chem Eng 32:1928–1937

Ifkovits JL, Burdick JA (2007) Review: photopolymerizable and degradable biomaterials for tissue engineering applications. Tissue Eng 13:2369–2385

Pereira RF, Carvalho A, Gil MH, Mendes A, Bártolo PJ (2013) Influence of Aloe vera on water absorption and enzymatic in vitro degradation of alginate hydrogel films. Carbohydr Polym 98:311–320

Lu W, Ma M, Xu H, Zhang B, Cao X, Guo Y (2015) Gelatin nanofibers prepared by spiral-electrospinning and cross-linked by vapor and liquid-phase glutaraldehyde. Mater Lett 140:1–4

Morsy R, Hosny M, Reisha F, Elnimr T (2017) Developing and physicochemical evaluation of cross-linked electrospun gelatin-glycerol nanofibrous membranes for medical applications. J Mol Struct 1135:222–227

Zhan J, Morsi Y, El-Hamshary H, Al-Deyab SS, Mo X (2016) In vitro evaluation of electrospun gelatin-glutaraldehyde nanofibers. Front Mater Sci 10:90–100

Sun K, Xie P, Wang Z, Su T, Shao Q, Ryu JE, Zhang X, Guo J, Shankar A, Li J, Fan R, Cao D, Guo Z (2017) Flexible polydimethylsiloxane/multi-walled carbon nanotubes membranous metacomposites with negative permittivity. Polymer 125:50–57

Cui H, Sinko PJ (2012) The role of crystallinity on differential attachment/proliferation of osteoblasts and fibroblasts on poly (caprolactone-co-glycolide) polymeric surfaces. Front Mater Sci 6:47–59

Heikkilä P, Harlin A (2008) Parameter study of electrospinning of polyamide-6. Eur Polym J 44:3067–3079

Monroy DAP, Bravo JMC, Mercado IES, Gómez LJV (2018). In tissue regeneration, HA. hay E-S Kaoud, Ed. InTech

Persson NE, McBride MA, Grover MA, Reichmanis E (2017) Automated analysis of orientational order in images of fibrillar materials. Chem Mater 29:3–14

Xue J, He M, Liu H, Niu Y, Crawford A, Coates PD, Chen D, Shi R, Zhang L (2014) Drug loaded homogeneous electrospun PCL/gelatin hybrid nanofiber structures for anti-infective tissue regeneration membranes. Biomaterials 35:9395–9405

Kai D, Liow SS, Loh XJ (2014) Biodegradable polymers for electrospinning: towards biomedical applications. Mater Sci Eng C 45:659–670

Xue J, He M, Liang Y, Crawford A, Coates P, Chen D, Shi R, Zhang L (2014) Fabrication and evaluation of electrospun PCL–gelatin micro-/nanofiber membranes for anti-infective GTR implants. J Mater Chem B 2:6867–6877

Mohanty S, Alm M, Hemmingsen M, Dolatshahi-Pirouz A, Trifol J, Thomsen P, Dufva M, Wolff A, Emnéus J (2016) 3D printed silicone-hydrogel scaffold with enhanced physicochemical properties. Biomacromolecules 17:1321–1329

Liu Y, Chan-Park MB (2010) A biomimetic hydrogel based on methacrylated dextran-graft-lysine and gelatin for 3D smooth muscle cell culture. Biomaterials 31:1158–1170

Beachley V, Wen X (2009) Fabrication of nanofiber reinforced protein structures for tissue engineering. Mater Sci Eng C 29:2448–2453

Chiono V, Tonda-Turo C (2015) Trends in the design of nerve guidance channels in peripheral nerve tissue engineering. Prog Neurobiol 131:87–104

Manoogian SJ, Bisplinghoff JA, Kemper AR, Duma SM (2012) Dynamic material properties of the pregnant human uterus. J Biomech 45:1724–1727

Omari EA, Varghese T, Kliewer MA, Harter J, Hartenbach EM (2015) Dynamic and quasi-static mechanical testing for characterization of the viscoelastic properties of human uterine tissue. J Biomech 48:1730–1736

Strauss JF, Barbieri RL, Eds, Yen & Jaffe’s (2019) Reproductive endocrinology: physiology, pathophysiology, and clinical management. Elsevier, Philadelphia, PA

Martins PALS, Filho ALS, Fonseca AMRM, Santos A, Santos L, Mascarenhas T, Natal Jorge RM, Ferreira AJM (2011) Uniaxial mechanical behavior of the human female bladder. Int Urogynecol J 22:991–995

Chantereau P, Brieu M, Kammal M, Farthmann J, Gabriel B, Cosson M (2014) Mechanical properties of pelvic soft tissue of young women and impact of aging. Int Urogynecol J 25:1547–1553

Atala A (2011) Tissue engineering of human bladder. Br Med Bull 97:81–104

Trabelsi O, Del Palomar AP, López-villalobos JL, Ginel A, Doblaré M (2010) Experimental characterization and constitutive modeling of the mechanical behavior of the human trachea. Med Eng Phys 32:76–82

Crowley C, Birchall M, Seifalian AM (2015) Trachea transplantation: from laboratory to patient: trachea transplantation. J Tissue Eng Regen Med 9:357–367

Liao J, Joyce EM, Sacks MS (2008) Effects of decellularization on the mechanical and structural properties of the porcine aortic valve leaflet. Biomaterials 29:1065–1074

Vesely I (2005) Heart valve tissue engineering. Circ Res 978:743–755

Feola A, Abramowitch S, Jones K, Stein S, Moalli P (2010) Parity negatively impacts vaginal mechanical properties and collagen structure in rhesus macaques. Am J Obstet Gynecol 203:595.e1-595.e8

Brandão R, da Silveira SD, Milhem Haddad J, Katalin I, de Jármy-Di BZ, Nastri F, GoncalvesMarkos Kawabata M, Silva Carramão SD, Alves Rodrigues C, ChadaBaracat C, Pedro Flores Auge A (2015) Multicenter, randomized trial comparing native vaginal tissue repair and synthetic mesh repair for genital prolapse surgical treatment. Int Urogynecol J 26:335–342

Karimi A, Navidbakhsh M, Alizadeh M, Shojaei A (2014) A comparative study on the mechanical properties of the umbilical vein and umbilical artery under uniaxial loading. Artery Res 8:51–56

AlhosseiniHamedani B, Navidbakhsh M, AhmadiTafti H (2012) Comparison between mechanical properties of human saphenous vein and umbilical vein. Biomed Eng 11:59

Sankaran KK, Vasanthan KS, Krishnan UM, Sethuraman S (2014) Development and evaluation of axially aligned nanofibres for blood vessel tissue engineering: small-diameter aligned nanofibrous vascular graft. J Tissue Eng Regen Med 8:640–651

Zorlutuna P, Elsheikh A, Hasirci V (2009) Nanopatterning of collagen scaffolds improve the mechanical properties of tissue engineered vascular grafts. Biomacromolecules 10:814–821

Mattei G, Ahluwalia A (2016) Sample, testing and analysis variables affecting liver mechanical properties: a review. Acta Biomater 45:60–71

Yoon No D, Lee K-H, Lee J, Lee S-H (2015) 3D liver models on a microplatform: well-defined culture, engineering of liver tissue and liver-on-a-chip. Lab Chip 15:3822–3837

NíAnnaidh A, Bruyère K, Destrade M, Gilchrist MD, Otténio M (2012) Characterization of the anisotropic mechanical properties of excised human skin. J Mech Behav Biomed Mater 5:139–148

Bashkatov AN, Genina EA, Tuchin VV (2011) Optical properties of skin, subcutaneous, and muscle tissues: a review. J Innov Opt Health Sci 4:9–38

Jansen LH, Rottier PB (1958) Some mechanical properties of human abdominal skin measured on excised strips. Dermatology 117:65–83

Dunn MG, Silver FH (1983) Viscoelastic behavior of human connective tissues: relative contribution of viscous and elastic components. Connect Tissue Res 12:59–70

Jacquemoud C, Bruyere-Garnier K, Coret M (2007) Methodology to determine failure characteristics of planar soft tissues using a dynamic tensile test. J Biomech 40:468–475

Acknowledgements

This work was supported by Iran national science foundation (INSF; Project No. 97014466), Yazd University Research Council and Yazd Reproductive Sciences Institute for their financial support. We are grateful to Dr. Behrouz Aflatoonian and Fatemeh Sadeghian-Nodoushan for their cooperation and technical support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest in the data presented in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dehghan, M., Nikukar, H. & Khajeh Mehrizi, M. Evaluation of physicochemical properties of polycaprolactone/gelatin/polydimethylsiloxane hybrid nanofibers as potential scaffolds for elastic tissue engineering. Polym. Bull. 79, 10881–10908 (2022). https://doi.org/10.1007/s00289-021-04071-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-04071-4