Abstract

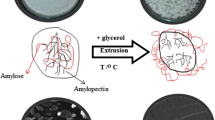

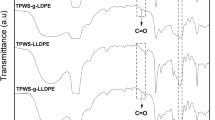

Plastic waste can serve as a symbolic expression of environmental pollution because of its prevalence and extremely slow degradation. A well-known example of synthetic plastics is low-density polyethylene (LDPE). A pragmatic approach to mitigate the environmental problems is to develop biodegradable plastic without compromising the quality of properties or increasing the price. To meet these requirements, one must turn to polymers from natural sources, such as starch. Starch is a fully biodegradable, semi-crystalline, non-toxic polymer with difficulties in processing. To obtain thermoplastic starch (TPS), a biodegradable glycerol plasticizer and sheer processing are necessary over a so-called gelatinization. Here, we aim to prepare and investigate sustainable and environmentally friendly packaging materials based on biodegradable blends, such as LDPE_TPS. The prepared blends were subjected to extensive physicochemical characterization to clarify the functional performance and biodegradability. Changes in structure, morphology and chemical composition before and after biodegradation were interpreted and correlated. Problems such as high interfacial tension due to high incompatibility between the non-polar polyolefin and the highly polar TPS were alleviated for some blends. The observation of mechanical, diffusive and composting parameters suggests that the modifier plays a crucial role in obtaining homogeneous polymer blends. The study of LDPE_TPS blends shows that it is possible to produce polymer blends with good biodegradability and balanced mechanical performance at a reasonable price.

Similar content being viewed by others

References

Plastics and Climate: The Hidden Costs of the Plastic Planet (2019). https://www.ciel.org/wp-content/uploads/2019/05/Plastic-and-Climate-FINAL-2019.pdf/ Accessed July 10, 2020

Avio CG, Gorbi S, Regoli F (2017) Plastics and microplastics in the oceans: from emerging pollutants to emerged threat. Mar Environ Res 128:2–11. https://doi.org/10.1016/j.marenvres.2016.05.012

Shah AA, Hasan F, Hameed A, Ahmed S (2008) Biological degradation of plastics: a comprehensive review. Biotechnol Adv 26:246–265. https://doi.org/10.1016/j.biotechadv.2007.12.005

Urbanek AK, Rymowicz W, Mirończuk AM (2018) Degradation of plastics and plastic-degrading bacteria in cold marine habitats. Appl Microbiol Biotechnol 102:7669–7678. https://doi.org/10.1007/s00253-018-9195-y

Laycock B, Nikolić M, Colwell JM, Gauthier E, Halley P, Bottle S, George G (2017) Lifetime prediction of biodegradable polymers. Prog Polym Sci 71:144–189. https://doi.org/10.1016/j.progpolymsci.2017.02.004

Naraya R (2017). In: Malinconico M (ed) Soil degradable bioplastics for a sustainable modern agriculture. Springer, Italy

Bulatović OV, Mandić V, Grgić KD, Ivančić A (2021) biodegradable polymer blends based on thermoplastic starch. J Polym Environ 29:492–508. https://doi.org/10.1007/s10924-020-01874-w

Halonen N, Pálvölgyi PS, Bassani A, Fiorentini C, Nair R, Spigno G, Kordas K (2020) Bio-based smart materials for food packaging and sensors – a review. Front Mater 7:82. https://doi.org/10.3389/fmats.2020.00082

Jolanta WK, Rydzkowski T, Borowski G, Szczypinski M, Klepka T, Thakur VK (2018) Recent progress in biodegradable polymers and nanocomposite-based packaging materials for sustainable environment. Int J Polym Anal Charact 23:383–395. https://doi.org/10.1080/1023666X.2018.1455382

Meran C, Ozturk O, Yuksel M (2008) Examination of the possibility of recycling and utilizing recycled polyethylene and polypropylene. Mater Des 29:701–705. https://doi.org/10.1016/j.matdes.2007.02.007

Peres AM, Pires RR, Oréfic RL (2016) Evaluation of the effect of reprocessing on the structure and properties of low density polyethylene/thermoplastic starch blends. Carbohydr Polym 136:210–215. https://doi.org/10.1016/j.carbpol.2015.09.047

Alshammari BA, Alotaibi MD, Alothman OY, Sanjay MR, Kian LK, Almutairi Z, Jawaid M (2019) A new study on characterization and properties of natural fibers obtained from olive tree (olea europaea L.) Residues. J Polym Environ 27:2334–2340. https://doi.org/10.1007/s10924-019-01526-8

Castro-Aguirre E, Auras R, Selke S, Rubino M, Marsh T (2017) Insights on the aerobic biodegradation of polymers by analysis of evolved carbon dioxide in simulated composting conditions. Polym Degrad Stabil 137:251–271. https://doi.org/10.1016/j.polymdegradstab.2017.01.017

Briassoulis D (2014) An overview on the mechanical behaviour of biodegradable agricultural films. J Polym Environ 12:65–81. https://doi.org/10.1023/B:JOOE.0000010052.86786.ef

Bota J, Vukoje M, Brozović M, Hrnjak-Murgić Z (2017) reduced water permeability of biodegradable PCL nanocomposite coated paperboard packaging. Chem Biochem Eng Q 31:417–424. https://doi.org/10.15255/CABEQ.2017.1126

Austrian Standards. Institute Austrian Standard: Analytical Methods and Quality Control for Waste Compost (1986) ÖNORM S 2023 Vienna, Austria

Bergey DH, Holt JG (1994) Bergey’s manual of determinative bacteriology. Lippincott Williams and Wilkins, Baltimore

Briški F, Kopčić N, Ćosić I, Kučić D, Vuković M (2012) Biodegradation of tobacco waste by composting: genetic identification of nicotine-degrading bacteria and kinetic analysis of transformations in leachate. Chem Pap 66:1103–1110. https://doi.org/10.2478/s11696-012-0234-3

Kolthoff IM, Sandel EB (1951) Inorganic Quantitative Analysis. Školska knjiga, Zagreb, Croatia.

Janjarasskul T, Krochta JM (2010) Edible packaging materials. Annu Rev Food Sci T 1:415–448. https://doi.org/10.1146/annurev.food.080708.100836

Guilbert S, Cuq B, Contard N (1997) Recent innovations in edible and/or biodegradable packaging materials. Food Addit Contam 14:741–751. https://doi.org/10.1080/02652039709374585

Kallel T, Nageotte VM, Jaziri M, Gerard JF, Eleuch B (2003) Compatibilization of PE/PS and PE/PP blends. I. effect of processing conditions and formulation. J Appl Polym Sci 90:2475–2484. https://doi.org/10.1002/APP.12873

Xing Z, Yang G (2010) Crystallization, melting behavior, and wettability of poly(e-caprolactone) and poly(e-caprolactone)/poly(Nvinylpyrrolidone) blends. J Appl Polym Sci 115:2747–2755. https://doi.org/10.1002/app.30069

Radonjič G, Musil V, Šmit I (1998) Compatibilization of polypropylene/polystyrene blends’ with poly(styrene-b-butadiene-b-styrene) block copolymer. J Appl Polym Sci 69:2625–2639. https://doi.org/10.1002/(SICI)1097-4628(19980926)69:13%3c2625::AID-APP13%3e3.0.CO;2-T

Clasen SH, Müller CMO, Pires ATN (2015) Maleic anhydride as a compatibilizer and plasticizer in TPS/PLA blends. J Braz Chem Soc 26:1583–1590. https://doi.org/10.5935/0103-5053.20150126

Siracusa V (2012) Food packaging permeability behaviour: a report. Int J Polym Sci. https://doi.org/10.1155/2012/302029

Turco R, Ortega-Toro R, Tesser R, Mallardo S, Collazo-Bigliardi S, Chiralt Boix A, Malinconico M, Rippa M, Di Serio M, Santagata G (2019) Poly (lactic acid)/thermoplastic starch films: effect of cardoon seed epoxidized oil on their chemicophysical, mechanical, and barrier properties. Coatings 9:574. https://doi.org/10.3390/coatings9090574

Obasi HC, Igwe IO, Ogbobe O, Aharanwa BC, Egeolu FC (2015) Processing and characterization of thermoplastic starch/polypropylene blends. IJSRSET 2394–4099:7–13

Rosa DS, Guedes CGF, Carvalho CL (2007) Processing and thermal, mechanical and morphological characterization of post-consumer polyolefins/thermoplastic starch blends. J Mater Sci 42:551–557. https://doi.org/10.1007/s10853-006-1049-9

Hanafi I, Razif N, Zulkifi A, Azura R (2010) Processability and miscibility of linear low density polyethylene/poly (vinyl alcohol) blends: in situ compatibilization with maleic anhydride. Iranian Polym J 19:297–308

Abdul MR, Ismail H, Mat TR (2009) Effects of PE-g-MA on tensile properties, morphology and water absorption of LDPE/thermoplastic sago starch blends. Polym Plast Technol Eng 48:919–924. https://doi.org/10.1080/03602550902995018

Abioye AA, Fasanmi OO, Rotimi DO, Abioye OP, Obuekwe CC, Afolalu SA, Okokpujie IP (2019) Review of the development of biodegradable plastic from synthetic polymers and selected synthesized nanoparticle starches. J Phys Conf Ser 1378:042064. https://doi.org/10.1088/1742-6596/1378/4/042064

Cerclé C, Sarazin P, Favis BD (2013) High performance polyethylene/thermoplastic starch blends through controlled emulsification phenomena. Carbohydr Polym 92138:148. https://doi.org/10.1016/j.carbpol.2012.08.107

Abdullah ZW, Dong Y (2019) Biodegradable and water resistant poly(vinyl) alcohol (pva)/starch (ST)/glycerol (GL)/halloysite nanotube (HNT) nanocomposite films for sustainable food packaging. Front Mater 6:58. https://doi.org/10.3389/fmats.2019.00058

Coates J (2000). In: Meyers RA (ed) Encyclopedia of analytical chemistry. John Wiley and Sons Ltd, Chichester

Tai NL, Adhikari R, Shanks R, Adhikari B (2019) Aerobic biodegradation of starch–polyurethane flexible films under soil burial condition: Changes in physical structure and chemical composition. Int Biodeterior Biodegrad 145:104793. https://doi.org/10.1016/j.ibiod.2019.104793

Slouf M, Synkova H, Baldrian J, Marek A, Kovarova J, Schmidt P, Dorschner H, Stephan M, Gohs U (2008) Structural changes of uhmwpe after e-beam irradiation and thermal treatment. J Biomed Mater Res Part B: - Appl Biomater 85B:240–251. https://doi.org/10.1002/jbm.b.30942

Slouf M, Michalkova D, Gajdosova V, Dybal J, Pilar J (2019) Prooxidant activity of phenolic stabilizers in polyolefins during accelerated photooxidation. Polym Degrad Stabil 166:307–324. https://doi.org/10.1016/j.polymdegradstab.2019.06.013

Pilar J, Michalkova D, Slouf M, Vackova T (2015) Long-term accelerated weathering of HAS stabilized PE and PP plaques: Compliance of ESRI, IR and MH data characterizing heterogeneity of photooxidation. Polym Degrad Stabil 120:114–121. https://doi.org/10.1016/j.polymdegradstab.2015.06.011

Grgić KD, Bera L, Miloloža M, Cvetnić M, Zokić TI, Miletić B, Leko T, Bulatović Bulatović OV (2020) Obrada aktivnog mulja s uređaja za pročišćavanje komunalnih otpadnih voda procesom kompostiranja. Hrvatske vode 28:1–8

Grgić KD, Domanovac VM, Domanovac T, Šabić M, Cvetnić M, Bulatović OV (2019) Influence of bacillus subtilis and pseudomonas aeruginosa bsw and clinoptilolite addition on the biowaste composting process. Arab J Sci Eng 44:5399–5409. https://doi.org/10.1007/s13369-018-03692-8

Kučić D, Kopčić N, Briški F (2013) Zeolite and potting soil sorption of CO2 and NH3 evolved during co-composting of grape and tobacco waste. Chem Pap 67:1–8. https://doi.org/10.2478/s11696-013-0322-z

Haug RT (1993) The practical handbook of compost engineering, Boca Raton Lewis.

Plachá D, Raclavská H, Kučerová M, Kuchačrová J (2013) Volatile fatty acid evolution in biomass mixture composts prepared in open and closed bioreactors. Waste Manag 33:1104–1112. https://doi.org/10.1016/j.wasman.2013.01.021

Herner Ž, Kučić D, Zelić B (2017) Biodegradation of imidacloprid by composting process. Chem Pap 71:13–20. https://doi.org/10.1007/s11696-016-0031-5

Vague M, Chan G, Roberts C, Swartz NA, Mellies JL (2019) Pseudomonas isolates degrade and form biofilms on polyethylene terephthalate (PET) plastic. bioRxiv, 647321. doi: https://doi.org/10.1101/647321

Awasthi S, Srivastava N, Singh T, Tiwary D, Mishra PK (2017) Biodegradation of thermally treated low density polyethylene by fungus Rhizopus oryzae NS . 3. Biotech 7:73. https://doi.org/10.1007/s13205-017-0699-4

Pravilnik o nusproizvodima i ukidanju statusa otpada (2020) NN 117/2014. https://narodne-novine.nn.hr/clanci/sluzbeni/2014_10_117_2217.html. Accessed 3 Dec 2020

Robledo MT, Martín MA, Gutiérrez MC, Toledo M, González I, Aranda E, Chica AF, Calvo C (2019) Sewage sludge composting under semi-permeable film at full-scale: evaluation of odour emissions and relationships between microbiological activities and physico-chemical variables. Environ Res 177:108624. https://doi.org/10.1016/j.envres.2019.108624

Hoque ME, Ye TJ, Yong LC, Dahlan KZM (2013) Sago starch-mixed low-density polyethylene biodegradable polymer: synthesis and characterization. J Mater. https://doi.org/10.1155/2013/365380

Johnson KE, Pometto AL, Nikolov ZL (1993) Degradation of degradable starch-polyethylene plastics in a compost environment. Appl Environ Microbiol 59:1155–1161. https://doi.org/10.1128/aem.59.4.1155-1161.1993

Karimi M, Biria D (2019) The promiscuous activity of alpha-amylase in biodegradation of low-density polyethylene in a polymer-starch blend. Sci Rep 9:2612. https://doi.org/10.1038/s41598-019-39366-0

Mierzwa-Hersztek M, Gondek K, Kopeć M (2019) Degradation of polyethylene and biocomponent-derived polymer materials: an overview. J Polym Environ 27:600–611. https://doi.org/10.1007/s10924-019-01368-4

Bikiaris D (1998) LDPE/starch blends compatibilized with PE-g-MA copolymers. Appl Polym Sci 70:1503–1521. https://doi.org/10.1002/(SICI)1097-4628(19981121)70:8%3c1503::AID-APP9%3e3.0.CO;2-%23

Abioye AA, Oluwadare OP, Abioye OP (2019) Environmental impact on biodegradation speed and biodegradability of polyethylene and ipomoea batatas starch blend. Int J Eng Res 41:145–154. https://doi.org/10.4028/www.scientific.net/JERA.41.145

Abioye AA, Obuekwe CC (2020) Investigation of the biodegradation of low-density polyethylene-starch Bi-polymer blends. Results Eng 5:100090. https://doi.org/10.1016/j.rineng.2019.100090

Bikiaris D, Prinos J, Koutsopoulos K, Vouroutzis N, Pavlidou E, Frangi N (1998) Panayiotou, C (1998) LDPE/plasticized starch blends containing PE-g-MA copolymer as compatibilizer. Polym Degrad Stab 59:287–291. https://doi.org/10.1016/S0141-3910(97)00126-2

Acknowledgements

This work has been funded by the projects: Advanced Water Treatment Technologies for Microplastics Removal (AdWaTMiR) IP-2019-04 of the Croatian Science Foundation and SLIPPERY SLOPE UIP-2019-02-2367 of the Croatian Science Foundation and PV-WALL PZS-2019-02-1555 in Research Cooperability Program of the Croatian Science Foundation funded by the European Union from the European Social Fund under the Operational Programme Efficient Human Resources 2014-2020.

Funding

This work has been funded by the projects: Advanced Water Treatment Technologies for Microplastics Removal (AdWaTMiR) IP-2019–04 of the Croatian Science Foundation and SLIPPERY SLOPE UIP-2019–02-2367 of the Croatian Science Foundation and PV-WALL PZS-2019–02-1555 in Research Cooperability Program of the Croatian Science Foundation funded by the European Union from the European Social Fund under the Operational Programme Efficient Human Resources 2014–2020.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by [VOB], [DKG], [VM], [MM], [JD], [VG] and [MS]. The first draft of the manuscript was written by [VOB and DKG], and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bulatović, V.O., Grgić, D.K., Mandić, V. et al. Biodegradation of LDPE_TPS blends under controlled composting conditions. Polym. Bull. 80, 3331–3357 (2023). https://doi.org/10.1007/s00289-021-03982-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03982-6