Abstract

In gas separation applications, a composite membrane formed by blending poly(ether‐block‐amide) and polyethersulfone seems promising due to its combined physicochemical properties. Such membranes' performance can be further improved by adding novel metal–organic frameworks such as zeolitic imidazolate framework-67 (ZIF-67). In this study, molecular dynamics (MD) simulation and Monte Carlo (MC) using material studio (MS) 2017 software were utilized to compute the structural, physical, and separation properties of the neat, hybrid, composite and mixed matrix membranes (MMMs). The morphological parameters investigated in this study include X-ray diffraction, glass transition temperature, fractional free volume and end-to-end distance. The addition of particles to the composite structure increased the amorphous state and d-space of the membrane. The glass transition temperature and fractional free volume of the MMMs increased with the increase in ZIF-67 particles, which indicates the improvement of the membrane performance in terms of thermal resistance and transport properties, respectively. Besides, transport properties such as diffusivity, solubility, permeability, and selectively for CO2, CH4, and N2 gases were studied. The evaluated parameters for the MMMs were higher than those of neat, hybrid, and composite membranes considered in this study. The mixed matrix membranes CO2 permeability filled with 20% ZIF-67 particles was improved by ~ 190 and ~ 240% for the neat Pebax and composite membranes (Pebax-PES), respectively. The selectivity of CO2/CH4 and CO2/N2 in the MMMs was improved by ~ 420 and ~ 80% compared to those of neat and composite membranes, respectively. The simulated results are in agreement with the available experimental data. Finally, the permeability and selectivity results show that the Px-PES-Z20% membrane is suitable for industrial applications, such as natural gas treatment.

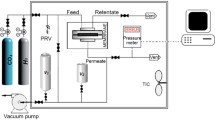

Graphic abstract

Similar content being viewed by others

Abbreviations

- a:

-

Simulation cell length in x-direction (Å)

- b:

-

Simulation cell length in y-direction (Å)

- c:

-

Simulation cell length in z-direction (Å)

- C:

-

Concentration of gas molecules in the simulation cell cm3 gas at STP/cm3 of polymer

- D:

-

Diffusivity (cm2/s)

- E:

-

Energy of configuration (kcal/mol)

- F:

-

Fractional free volume

- fi :

-

Fugacity of component i in the gas phase (bar)

- Ni :

-

Current number of component i molecules in the membrane cell

- P:

-

Total pressure (bar)

- p:

-

Permeability Barrer = [10–10 cm3 (STP) cm cm−2 s−1 cmHg−1]

- Pacc:

-

Acceptance probability

- r(t)z:

-

Final position vectors of the center of mass of the gas molecules over the time interval t (Å)

- r(0)z:

-

Initial position vectors of the center of mass of the gas molecules (Å)

- S:

-

Solubility (cm3 gas at STP/(cm3 of polymer. cmHg)

- t:

-

Simulation time (ps)

- tM:

-

Membrane thickness (Å)

- tg :

-

Glass transition temperature (K)

- V:

-

Volume of membrane cell (Å3)

- VM :

-

Volume of membrane region (Å3)

- VO :

-

Occupied volume of the polymer chains (Å3)

- VvdW :

-

Van der Waals volume of the polymer chains (Å3)

- VF :

-

Free volume (Å3)

- Vfeed :

-

Volume of feed region (Å3)

- αAB :

-

Selectivity

- ε/kB:

-

Lennard-Jones interaction parameter (K)

- σ:

-

Kinetic diameter of gases (Å)

References

Sridhar S et al (2007) Separation of binary mixtures of carbon dioxide and methane through sulfonated polycarbonate membranes. J Appl Polym Sci 105(4):1749–1756. https://doi.org/10.1002/app.24628

Salahshoori I et al (2020) Investigation of experimental results and D-optimal design of hafnium ion extraction from aqueous system using emulsion liquid membrane technique. J Iran Chem Soc. https://doi.org/10.1007/s13738-020-02007-9

Dharupaneedi SP et al (2019) Membrane-based separation of potential emerging pollutants. Sep Purif Technol 210:850–866. https://doi.org/10.1016/j.seppur.2018.09.003

Kamali M et al (2019) Sustainability considerations in membrane-based technologies for industrial effluents treatment. Chem Eng J 368:474–494. https://doi.org/10.1016/j.cej.2019.02.075

Noble RD (2011) Perspectives on mixed matrix membranes. J Membr Sci 378(1):393–397. https://doi.org/10.1016/j.memsci.2011.05.031

Nasirian D et al (2019) Investigation of the gas permeability properties from polysulfone/polyethylene glycol composite membrane. Polym Bull. https://doi.org/10.1007/s00289-019-03031-3

Wang M et al (2017) Recent advances on mixed matrix membranes for CO2 separation. Chin J Chem Eng 25(11):1581–1597. https://doi.org/10.1016/j.cjche.2017.07.006

Aroon M et al (2010) Performance studies of mixed matrix membranes for gas separation: a review. Sep Purif Technol 75(3):229–242

Mosleh S et al (2016) Synthesis and characterization of rubbery/glassy blend membranes for CO2/CH4 gas separation. J Polym Res 23(6):120. https://doi.org/10.1007/s10965-016-1005-6

Han Y et al (2018) Recent advances in polymeric membranes for CO2 capture. Chin J Chem Eng 26(11):2238–2254. https://doi.org/10.1016/j.cjche.2018.07.010

Mannan HA et al (2013) Recent applications of polymer blends in gas separation membranes. Chem Eng Technol 36(11):1838–1846

Surya Murali R et al (2014) Nanosilica and H-mordenite incorporated poly(ether-block-amide)-1657 membranes for gaseous separations. Microporous Mesoporous Mater 197:291–298. https://doi.org/10.1016/j.micromeso.2014.07.001

Vinoba M et al (2017) Recent progress of fillers in mixed matrix membranes for CO2 separation: a review. Sep Purif Technol 188:431–450

Lin R-B et al (2019) Exploration of porous metal–organic frameworks for gas separation and purification. Coord Chem Rev 378:87–103. https://doi.org/10.1016/j.ccr.2017.09.027

Hegde M et al (2015) Gas transport in metal organic framework–polyetherimide mixed matrix membranes: the role of the polyetherimide backbone structure. Polymer 81:87–98. https://doi.org/10.1016/j.polymer.2015.11.002

Chen B et al (2014) Zeolitic imidazolate framework materials: recent progress in synthesis and applications. J Mater Chem A 2(40):16811–16831. https://doi.org/10.1039/C4TA02984D

Mahdi EM et al (2016) Dynamic molecular interactions between polyurethane and ZIF-8 in a polymer-MOF nanocomposite: microstructural, thermo-mechanical and viscoelastic effects. Polymer 97:31–43. https://doi.org/10.1016/j.polymer.2016.05.012

Gao Z et al (2020) Strategies for electromagnetic wave absorbers derived from zeolite imidazole framework (ZIF-67) with ferrocene containing polymers. Polymer 202:122679. https://doi.org/10.1016/j.polymer.2020.122679

Meshkat S et al (2019) Comparison between ZIF-67 and ZIF-8 in Pebax® MH-1657 mixed matrix membranes for CO2 separation. Sep Purif Technol 235:116150. https://doi.org/10.1016/j.seppur.2019.116150

Murali RS et al (2010) Gas permeation behavior of Pebax-1657 nanocomposite membrane incorporated with multiwalled carbon nanotubes. Ind Eng Chem Res 49(14):6530–6538

Bernardo P et al (2012) Gas transport properties of Pebax®/room temperature ionic liquid gel membranes. Sep Purif Technol 97:73–82. https://doi.org/10.1016/j.seppur.2012.02.041

Surya Murali R et al (2014) Mixed matrix membranes of Pebax-1657 loaded with 4A zeolite for gaseous separations. Sep Purif Technol 129:1–8. https://doi.org/10.1016/j.seppur.2014.03.017

Zhou X et al (2014) Polyethersulfone/polyetherethersulfone copolymers with the same chemical composition and different melt-viscosity. J Appl Polym Sci. https://doi.org/10.1002/app.40149

Yu J et al (2013) An approach to prepare defect-free PES/MFI-type zeolite mixed matrix membranes for CO2/N2 separation. J Mater Sci 48:3782–3788. https://doi.org/10.1007/s10853-013-7178-z

Tavangar T et al (2020) Textile waste, dyes/inorganic salts separation of cerium oxide-loaded loose nanofiltration polyethersulfone membranes. Chem Eng J 385:123787. https://doi.org/10.1016/j.cej.2019.123787

Jusoh N et al (2016) Current development and challenges of mixed matrix membranes for CO2/CH4 separation. Sep Purif Rev 45(4):321–344. https://doi.org/10.1080/15422119.2016.1146149

De Angelis MG et al (2012) Gas sorption and permeation in mixed matrix membranes based on glassy polymers and silica nanoparticles. Curr Opin Chem Eng 1(2):148–155. https://doi.org/10.1016/j.coche.2012.02.007

Jomekian A et al (2016) CO2/CH4 separation by high performance co-casted ZIF-8/Pebax 1657/PES mixed matrix membrane. J Nat Gas Sci Eng 31:562–574. https://doi.org/10.1016/j.jngse.2016.03.067

Yamamoto T (2009) Computer modeling of polymer crystallization – Toward computer-assisted materials’ design. Polymer 50(9):1975–1985. https://doi.org/10.1016/j.polymer.2009.02.038

Jawalkar SS et al (2005) Molecular modeling on the binary blend compatibility of poly(vinyl alcohol) and poly(methyl methacrylate): an atomistic simulation and thermodynamic approach. J Phys Chem B 109(32):15611–15620. https://doi.org/10.1021/jp051206v

Murray-Smith D (2019) Computer simulation validation fundamental concepts, methodological frameworks and philosophical perspectives. In: Beisbart Claus, Saam Nicole J (eds) The use of experimental data in simulation model validation. Springer, Cham, pp 357–382. https://doi.org/10.1007/978-3-319-70766-2_15

Hollingsworth SA et al (2018) Molecular dynamics simulation for all. Neuron 99(6):1129–1143. https://doi.org/10.1016/j.neuron.2018.08.011

Allen MP (2004) Introduction to molecular dynamics simulation. Comput soft matter synth polym prot 23:1–28

Hatami A et al (2019) The effect of ZIF-90 particle in Pebax/PSF composite membrane on the transport properties of CO2, CH4 and N2 gases by molecular dynamics simulation method. Chin J Chem Eng. https://doi.org/10.1016/j.cjche.2019.12.011

Zhao J et al (2017) Overview of polymer nanocomposites: Computer simulation understanding of physical properties. Polymer 133:272–287. https://doi.org/10.1016/j.polymer.2017.10.035

Trinh TT et al (2016) A molecular dynamics simulation study on separation selectivity of CO2/CH4 mixture in mesoporous carbons. Energ Procedia 86:144–149. https://doi.org/10.1016/j.egypro.2016.01.015

Prathab B et al (2007) Molecular dynamics simulations to investigate polymer–polymer and polymer–metal oxide interactions. Polymer 48(1):409–416. https://doi.org/10.1016/j.polymer.2006.11.014

Golzar K et al (2017) Separation of gases by using pristine, composite and nanocomposite polymeric membranes: a molecular dynamics simulation study. J Membr Sci 539:238–256. https://doi.org/10.1016/j.memsci.2017.06.010

Jeyranpour F et al (2016) The thermo-mechanical properties estimation of fullerene-reinforced resin epoxy composites by molecular dynamics simulation–a comparative study. Polymer 88:9–18

Jawalkar SS et al (2007) Molecular dynamics simulations to compute diffusion coefficients of gases into polydimethylsiloxane and poly{(1,5- naphthalene)-co-[1,4-durene-2,2′-bis(3,4-dicarboxyl phenyl)hexafluoropropane diimide]}. Polym Int 56(7):928–934. https://doi.org/10.1002/pi.2226

Sun Y et al (2018) Molecular dynamics simulation of cross-linked epoxy resin and its interaction energy with graphene under two typical force fields. Comput Mater Sci 143:240–247

Narayan R et al (2006) Viscosity behavior of hydroxylated and acetoacetylated polyesters. J Appl Polym Sci 100(3):2422–2435. https://doi.org/10.1002/app.23341

Jena KK et al (2007) Hyperbranched polyesters: synthesis, characterization, and molecular simulations. J Phys Chem B 111(30):8801–8811. https://doi.org/10.1021/jp070513t

Eslami M et al (2016) The compatibility of tacrine molecule with poly (n-butylcyanoacrylate) and chitosan as efficient carriers for drug delivery: a molecular dynamics study. Eur J Pharm Sci 82:79–85

Jawalkar SS et al (2006) Molecular modeling simulations and thermodynamic approaches to investigate compatibility/incompatibility of poly(l-lactide) and poly(vinyl alcohol) blends. Polymer 47(23):8061–8071. https://doi.org/10.1016/j.polymer.2006.09.030

Jawalkar SS et al (2007) Molecular modeling simulations to predict compatibility of poly(vinyl alcohol) and chitosan blends: a comparison with experiments. J Phys Chem B 111(10):2431–2439. https://doi.org/10.1021/jp0668495

Jawalkar SS et al (2008) Molecular dynamics simulations on the blends of poly(vinyl pyrrolidone) and poly(bisphenol-A-ether sulfone). J Appl Polym Sci 108(6):3572–3576. https://doi.org/10.1002/app.28005

Prathab B et al (2006) Molecular modeling and atomistic simulation strategies to determine surface properties of perfluorinated homopolymers and their random copolymers. Polymer 47(19):6914–6924. https://doi.org/10.1016/j.polymer.2006.07.034

Prathab B et al (2007) Computation of surface energy and surface segregation phenomena of perfluorinated copolymers and blends – a molecular modeling approach. Polymer 48(1):417–424. https://doi.org/10.1016/j.polymer.2006.10.043

Prathab B et al (2007) Atomistic simulations to compute surface properties of Poly(N-vinyl-2-pyrrolidone) (PVP) and blends of PVP/Chitosan. Langmuir 23(10):5439–5444. https://doi.org/10.1021/la063228u

Prathab B et al (2007) Molecular modeling study on surface, thermal, mechanical and gas diffusion properties of chitosan. J Polym Sci, Part B: Polym Phys 45(11):1260–1270. https://doi.org/10.1002/polb.21109

Khosravanian A et al (2018) Grand canonical Monte Carlo and molecular dynamics simulations of the structural properties, diffusion and adsorption of hydrogen molecules through poly (benzimidazoles)/nanoparticle oxides composites. Int J Hydrogen Energy 43(5):2803–2816

Golzar K et al (2014) Molecular simulation study of penetrant gas transport properties into the pure and nanosized silica particles filled polysulfone membranes. J Membr Sci 451:117–134. https://doi.org/10.1016/j.memsci.2013.09.056

Jeyranpour F et al (2016) The thermo-mechanical properties estimation of fullerene-reinforced resin epoxy composites by molecular dynamics simulation – a comparative study. Polymer 88:9–18. https://doi.org/10.1016/j.polymer.2016.02.018

Masheane M et al (2018) PES/Quaternized-PES blend anion exchange membranes: investigation of polymer compatibility and properties of the blend. J Membr Sci Res 4:93–100. https://doi.org/10.22079/JMSR.2018.74701.1163

Radjai F et al (2011) Periodic boundary conditions. In: Discrete numerical modeling of granular materials. Applied mathematics in science. Wiley, New York, pp 181–198

Schlick T (2002) Multivariate minimization in computational chemistry. In: Schlick T (ed) Molecular modeling and simulation: an interdisciplinary guide. Springer, New York, pp 305–344. https://doi.org/10.1007/978-0-387-22464-0_10

Raghu AV et al (2006) Synthesis, characterization, and molecular modeling studies of novel polyurethanes based on 2,2′-[ethane-1,2-diylbis(nitrilomethylylidene)]diphenol and 2,2′-[hexane-1,6-diylbis(nitrilomethylylidene)] diphenol hard segments. J Polym Sci, Part A: Polym Chem 44(20):6032–6046. https://doi.org/10.1002/pola.21686

Golzar K et al (2017) Effect of pristine and functionalized single- and multi-walled carbon nanotubes on CO 2 separation of mixed matrix membranes based on polymers of intrinsic microporosity (PIM-1): a molecular dynamics simulation study. J Mol Model 23(9):266. https://doi.org/10.1007/s00894-017-3436-3

Bragg WH et al (1913) The reflection of X-rays by crystal. In: Proceeding of the Royal Society of London Series A. Containing Papers of a Mathematical, Physical and Engineering science, vol 605, pp 428–438. https://doi.org/10.1098/rspa.1913.0040

Asghari M et al (2017) Molecular simulation and experimental investigation of temperature effect on chitosan-nanosilica supported mixed matrix membranes for dehydration of ethanol via pervaporation. J Mol Liq 246:7–16. https://doi.org/10.1016/j.molliq.2017.09.045

Tan X et al (2019) A review on porous polymeric membrane preparation Part ii production techniques with polyethylene, polydimethylsiloxane, polypropylene, polyimide, and polytetrafluoroethylene. Polymers. https://doi.org/10.3390/polym11081310

Sharma P et al (2019) Stable polymeric chain configuration producing high performance PEBAX-1657 membrane for CO2 separation. Nanoscale Adv. https://doi.org/10.1039/C9NA00170K

Laghaei M et al (2016) The role of compatibility between polymeric matrix and silane coupling agents on the performance of mixed matrix membranes: polyethersulfone/MCM-41. J Membr Sci 513:20–32. https://doi.org/10.1016/j.memsci.2016.04.039

Corrado T et al (2020) Macromolecular design strategies toward tailoring free volume in glassy polymers for high performance gas separation membranes. Mol Syst Des Eng. https://doi.org/10.1039/C9ME00099B

Guo X et al (2019) Mixed-matrix membranes for CO2 separation: role of the third component. J Mater Chem A 7(43):24738–24759. https://doi.org/10.1039/C9TA09012F

Abdelrasoul A et al (2015) Mass transfer mechanisms and transport resistances in membrane separation process. Mass Transfer-Adv Process Modell. https://doi.org/10.5772/60866

Pazirofteh M et al (2019) Separation and transport specification of a novel PEBA-1074/PEG-400/TiO2 nanocomposite membrane for light gas separation: molecular simulation study. J Mol Liq 291:111268. https://doi.org/10.1016/j.molliq.2019.111268

Tanis I et al (2018) A comparison of pure and mixed-gas permeation of nitrogen and methane in 6FDA-based polyimides as studied by molecular dynamics simulations. Comput Mater Sci 141:243–253. https://doi.org/10.1016/j.commatsci.2017.09.028

Semsarzadeh MA et al (2012) Characterization and gas permeability of polyurethane and polyvinyl acetate blend membranes with polyethylene oxide–polypropylene oxide block copolymer. J Membr Sci. https://doi.org/10.1016/j.memsci.2012.01.035

Car A et al (2008) PEG modified poly (amide-b-ethylene oxide) membranes for CO2 separation. J Membr Sci 307(1):88–95

Dashti A et al (2018) Molecular dynamics, grand canonical Monte Carlo and expert simulations and modeling of water–acetic acid pervaporation using polyvinyl alcohol/tetraethyl orthosilicates membrane. J Mol Liq 265:53–68. https://doi.org/10.1016/j.molliq.2018.05.078

Mushardt H et al (2014) Development of solubility selective mixed matrix membranes for gas separation. Chem Ing Tec 86(1–2):83–91. https://doi.org/10.1002/cite.201300074

Marand E et al (2012) The role of solubility partition coefficient at the mixed matrix interface in the performance of mixed matrix membranes. J Membr Sci 415:871–877

Poloni R et al (2014) Understanding trends in CO2 adsorption in metal–organic frameworks with open-metal sites. J Phys Chem Lett 5(5):861–865

Park J et al (2012) Tuning metal–organic frameworks with open-metal sites and its origin for enhancing CO2 affinity by metal substitution. J Phys Chem Lett 3(7):826–829

Yu D et al (2013) A combined experimental and quantum chemical study of CO 2 adsorption in the metal–organic framework CPO-27 with different metals. Chem Sci 4(9):3544–3556

Reijerkerk S (2010) Polyether based block copolymer membranes for CO2 separation. Doctoral dissertation, University of Twente, Enschede, Netherlands. https://doi.org/10.3990/1.9789036529815

Kanehashi S et al (2010) Analysis of permeability; solubility and diffusivity of carbon dioxide; oxygen; and nitrogen in crystalline and liquid crystalline polymers. J Membr Sci 365:40–51. https://doi.org/10.1016/j.memsci.2010.08.035

Huang Z et al (2006) Enhanced gas separation properties by using nanostructured PES-Zeolite 4A mixed matrix membranes. J Appl Polym Sci 101(6):3800–3805

Meshkat S et al (2018) Mixed matrix membranes based on amine and non-amine MIL-53(Al) in Pebax® MH-1657 for CO2 separation. Sep Purif Technol 200:177–190. https://doi.org/10.1016/j.seppur.2018.02.038

Dehghani M et al (2017) Molecular dynamics and Monte Carlo simulation of the structural properties, diffusion and adsorption of poly (amide-6-b-ethylene oxide)/Faujasite mixed matrix membranes. J Mol Liq 242:404–415. https://doi.org/10.1016/j.molliq.2017.07.034

Wang S et al (2016) Advances in high permeability polymer-based membrane materials for CO 2 separations. Energy Environ Sci 9(6):1863–1890

Chernova E et al (2016) Enhanced gas separation factors of microporous polymer constrained in the channels of anodic alumina membranes. Sci Rep 6:31183

Acknowledgements

The authors would like to thank computational support for this research, which was provided by the Science and Research Branch of the Islamic Azad University (Tehran SRBIAU).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors state that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Salahshoori, I., Babapoor, A. & Seyfaee, A. Elevated performance of the neat, hybrid and composite membranes by the addition of nanoparticles (ZIF-67): A molecular dynamics study. Polym. Bull. 79, 3595–3630 (2022). https://doi.org/10.1007/s00289-021-03673-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03673-2