Abstract

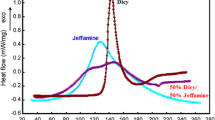

There is a great number of reports with the aim to reduce the inherent brittleness of epoxy resins through their modification with different types of reacting and non-reacting additives, in order to diversify their applications. In this work, the toughening effect of polydimethylsiloxane, diglycidyl ether (PDMS-DGE) as well as this rubber functionalized with 1,2-diaminocyclohexane (PDMS-DGE-DCH) on the bisphenol-A diglycidyl ether/1,2-diaminocyclohexane epoxy resin (DGEBA/1,2-DCH) was characterized by differential scanning calorimetry, DSC, and dynamic mechanical analysis, DMA. The results were correlated with those from energy-dispersive X-ray spectroscopy, EDS X-ray, scanning electronic microscopy, SEM, thermogravimetric analysis, and tension tests. The epoxy resin added with 10 phr (parts per hundred of resin) PDMS-DGE underwent phase separation evidenced by voids of c.a. 0.7 µm left after extraction of PDMS-DGE, while Young's modulus and glass transition temperature, Tg, did not decrease significantly. In contrast, the PDMS-DGE-DCH modifier at 10 phr yielded epoxy resins with two lower partially overlapping Tg over a broader temperature range and increased on both the tensile strength and the tensile strain at the break by 2.8- and 16.8-fold, respectively. No voids were observed on the SEM images after subjected to extraction conditions with acetone, and EDS X-ray elemental mapping revealed Si atoms uniformly distributed on all the fracture-surface, proving that PDMS-DGE-DCH took part in the cure reaction into the network of epoxy resin.

Similar content being viewed by others

References

Pham HQ, Marks MJ (2004) Epoxy resins. In: Mark HF (ed) Encyclopedia of polymer science and technology, 3rd edn. Wiley, New York

Li Y, Wong CP (2006) Recent advances of conductive adhesives as a lead-free alternative in electronic packaging: materials, processing, reliability and applications. Mater Sci Eng R Rep 51:1–35. https://doi.org/10.1016/j.mser.2006.01.001

Marouf BT, Bagheri R (2016) Applications of epoxy/rubber blends. In: Parameswaranpillai J, Hameed N, Pionteck J (eds) Handbook of epoxy blends, 1st edn. Springer, Switzerland, pp 1–28. https://doi.org/10.1007/978-3-319-18158-5-14-2

Kurahatti R, Surendranathan AO, Kori N, Singh SA, Kumar AV, Srivastava S (2010) Defense applications of polymer nanocomposites. Defense Sci J 60:551–563. https://doi.org/10.14429/dsj.60.578

Saba N, Jawaid M, Paridah AOY, M, Hassan A, (2016) Recent advances in epoxy resin, natural fiber-reinforced epoxy composites and their applications. J Reinf Plast Compos 35:447–470. https://doi.org/10.1177/0731684415618459

Tsai JL, Huang BH, Cheng YL (2011) Enhancing fracture toughness of glass/epoxy composites for wind blades using silica nanoparticles and rubber particles. Proced Eng 14:1982–1987. https://doi.org/10.1016/j.proeng.2011.07.249

Rosso P, Ye L, Friedrich K, Sprenger S (2006) A toughened epoxy resin by silica nanoparticle reinforcement. J Appl Polym Sci 100:1849–1855. https://doi.org/10.1002/app.22805

Kinloch AJ (2003) Toughening epoxy adhesives to meet today’s challenge. MRS Bull 28:445–448. https://doi.org/10.1557/mrs2003.126

Ahmadi Z (2019) Nanostructured epoxy adhesives: a review. Progr Org Coat 135:449–453. https://doi.org/10.1016/j.porgcoat.2019.06.028

Vijaykumar MS, Saravanan R, Rajasekar K, Dhandapani NV (2018) Development and testing of nano-clay composites for pressure pad application. Int J Vehicule Structr Syst 10:103–107. https://doi.org/10.4273/ijvss.10.2.06

Zabihi O, Ahmadi M, Nikafshar S, Preyeswary KC, Naebe M (2018) A technical review on epoxy-clay nanocomposites: structure, properties, and their applications in fiber reinforced composites. Compos Part B Eng 135:1–24. https://doi.org/10.1016/j.compositesb.2017.09.066

Fellahi S, Chikhi N, Bakar M (2001) Modification of epoxy resin with kaolin as a toughening agent. J Appl Polym Sci 82:861–878. https://doi.org/10.1002/app.1918

Polizos G, Tuncer E, Sauers I, More KL (2010) Physical properties of epoxy resin/titanium dioxide nanocomposites. Polym Eng Sci 51:87–93. https://doi.org/10.1002/pen.21783

Carballeira P, Haupert F (2008) Toughening effects of titanium dioxide nanoparticles on TiO2/epoxy resin nanocomposites. Polym Compos 31:1241–1246. https://doi.org/10.1002/pc.201911

Bajpai A, Alapati AK, Klingler A, Wetzel B (2018) Tensile properties, fracture mechanics properties and toughening mechanisms of epoxy systems modified with soft block copolymers, rigid TiO2 nanoparticles and their hybrids. J Compos Sci 2:72. https://doi.org/10.3390/jcs2040072

Pinto D, Bernardo L, Amaro A, Lopes S (2015) Mechanical properties of epoxy nanocomposites using titanium dioxide as reinforcement—a review. Constr Build Mater 95:506–524. https://doi.org/10.1016/j.conbuiltmat.2015.07.124

Vietri U, Guadagno L, Raimondo M, Vertuccio L, Lafdi K (2014) Nanofilled epoxy adhesive for structural aeronautic materials. Compos Part B Eng 61:73–83. https://doi.org/10.1016/j.compositesb.2014.01.032

Kinloch AJ, Taylor AC (2006) The mechanical properties and fracture behavior of epoxy-inorganic micro and nano-composites. J Mater Sci 41:3271–3297. https://doi.org/10.1007/s10853-005-5472-0

Jakubinek MB, Ashrafi B, Zhang Y, Martinez-Runi Y, Kingston CT, Johnston A, Simard B (2015) Single-walled carbon nanotube-epoxy composites for structural and conductive aerospace adhesives. Compos Part B Eng 69:87–93. https://doi.org/10.1016/j.compositesb.2014.09.022

Hernández-Pérez A, Avilés F, May-Pat A, Valadez-González A, Herrera-Franco PJ, Bartolo-Pérez P (2008) Effective properties of multiwalled carbon nanotube/epoxy composites using two different tubes. Compos Sci Technol 68:1422–1431. https://doi.org/10.1016/j.composcitech.2007.11.001

Herrera-Sosa ML, Valadez-González A, Vázquez-Torres H, Mani-González PJ, Herrera-Franco P (2017) Effect of the surface modification using MWCNTs with different L/D by two different methods of deposition on the IFSS of single carbon fiber-epoxy resin composite. Carbon Lett (Korea Science) 24:18–27. https://doi.org/10.5714/CL.2017.24.018

Domun N, Hadavinia H, Zhang T, Sainsbury T, Light GH, Valid S (2015) Improving fracture toughness and strength of epoxy using nanomaterials—a review of current status. Nanoscale 7:10294–10329. https://doi.org/10.1039/c5nr01354b

Thomas R, Durix S, Sinturel C, Omonov T, Goossens S, Groeninckx G, Moldenaers P, Thomas S (2007) Cure kinetics, morphology and miscibility of modified DGEBA-based epoxy resin—effects of a liquid rubber inclusion. Polymer 48:1695–1710. https://doi.org/10.1016/j.polymer.2007.01.018

Kong J, Tang Y, Zhang X (2008) Gu J (2008) Synergic effect of acrylate liquid rubber and bisphenol A on toughness of epoxy resins. Polym Bull 60:229–236. https://doi.org/10.1007/s00289-007-0862-x

Tan SK, Ahmad S, Chia CH, Mamum A, Heim HP (2013) A comparison study of liquid natural rubber (LNR) and liquid epoxidized natural rubber (LENR) as the toughening agent for epoxy. Am J Mater Sci 3:55–61. https://doi.org/10.5923/j.materials.20130303.02

Vázquez A, Rojas AJ, Adabbo HE, Borrajo J, Williams RJJ (1987) Rubber-modified thermosets: prediction of the particle size distribution of dispersed domains. Polymer 28:1156–1164. https://doi.org/10.1016/0032-3861(87)90259-X

Thomas S, Sinturel C, Thomas R (2014) Micro- and nanostructured epoxy/rubber blends. Wiley VCH, Weinheim

Kinloch AJ, Mohammed RD, Taylor AC (2005) The effect of silica nanoparticles and rubber particles on the toughness of multiphase thermosetting epoxy polymers. J Mater Sci 40:5083–5086. https://doi.org/10.1007/s10853-005-1716-2

Kam KW, The PL, Osman H, Yeoh CJ (2019) Characterization of different forms of vulcanized natural rubbers as elastomer spacer and toughening agent in two-matrix filled epoxy/natural rubber/graphene nano-platelets system. J Appl Polym Sci 136:47188. https://doi.org/10.1002/APP.47198

Ayandele E, Sarkar B, Alexandridis P (2012) Polyhedral oligomeric silsesquioxane (POSS)-containing polymer nanocomposites. Nanomaterials 2:445–475. https://doi.org/10.3390/nano2040445

Mishra K, Pandey G, Singh RP (2017) Enhancing the mechanical properties of an epoxy resin using polyhedral oligomeric silsesquioxane (POSS) as nano-reinforcement. Polym Test 62:210–218. https://doi.org/10.1016/j.polymertesting.2017.06.031

Cedeño AJ, Vázquez-Torres H (2005) Kinetic study of the effect of poly(phenyl sulfone) on the curing of an epoxy/amine resin by conventional and by temperature-modulated differential scanning calorimetry. Polym Int 54:1141–1152. https://doi.org/10.1002/pi.1818

Cedeño AJ, Vázquez-Torres H (2010) Kinetic study on the effect of curing polyphenylsulfone epoxy resin/amine by differential calorimetry scanning conventional and modulated temperature Part II. Polímeros 20:287–294. https://doi.org/10.1590/S0104-14282010005000044

Jia LY, Zhang C, Du ZJ, Li CJ, Li HQ (2007) Preparation of interpenetrating polymer networks of epoxy/polydimethylsiloxane in a common solvent of the precursors. Polym J 39:593–597. https://doi.org/10.1295/polymj.PJ2006237

Khoee S, Hassani N (2010) Adhesion strength improvement of epoxy resin reinforced with nanoelastomeric copolymer. Mater Sci Eng A 527:657–6567. https://doi.org/10.1016/j.msea.2010.07.013

Karger-Kocsis J (2016) Self-healing properties of epoxy resins with poly(ε-caprolactone) healing agent. Polym Bull 73:3081–3093. https://doi.org/10.1007/s00289-016-1642-2

Hillmyer MA, Lipic PM, Hajduk DA, Bates AK, FS, (1997) Self-assembly and polymerization of epoxy resin-amphiphilic block copolymer nanocomposites. J Am Chem Soc 119:2749–2750. https://doi.org/10.1021/ja963622m

Lipic PM, Bates FS, Hillmyer MA (1998) Nanostructured thermosets from self-assembled amphiphilic blockcopolymer/epoxy resin mixtures. J Am Chem Soc 120:8963–8970. https://doi.org/10.1021/ja981544s

Thompson ZJ, Hillmyer MA, Liu J, Sue HJ, Dettloff M (2009) Bates FS (2009) block copolymer toughened epoxy: role of cross-link density. Macromolecules 42:2333–2335. https://doi.org/10.1021/ma900061b

Chu WC, Lin WS, Kuo SW (2016) Flexible epoxy resin formed upon blending with a triblock copolymerthrough reaction-induced microphase separation. Materials 9:449. https://doi.org/10.3390/90.3390/ma9060449

Su WC, Tsai FC, Huang CF, Dai L, Kuo SW (2019) Flexible epoxy resins formed by blending with the diblock copolymer PEO-b-PCL and using a hydrogen-bonding benzoxazine as the curing agent. Polymers 11:201. https://doi.org/10.3390/polym11020201

Ruiz-Pérez L, Royston GJ, Fairclough PA, Ryan AJ (2008) Toughening by nanostructure. Polymer 49:4475–4488. https://doi.org/10.1016/j.polymer.2008.07.048

Jerzy J, Chrusciel JJ, Lesniak E (2015) Modification of epoxy resins with functional silanes, polysiloxanes, silsesquioxanes, silica and silicates. Progr Polym Sci 41:67–121. https://doi.org/10.1016/j.progpolymsci.2014.08.001

Vilčáková J, Kutějová L, Jurča M, Moučka R, Vícha R, Sedlačík M, Kovalcik A, Machovský M, Kazantseva N (2018) Enhanced charpy impact strength of epoxy resin modified with vinyl-terminated polydimethylsiloxane. J Appl Polym Sci 135:45720. https://doi.org/10.1002/APP.45720

Deng LL, Shen MM, Yu J, Wu K, Ha CY (2012) Preparation, characterization, and flame retardancy of novel rosin-based siloxane epoxy resins. Ind Eng Chem Res 51:8178–8184. https://doi.org/10.1021/ie201364q

Smith JA, Mele E, Rimington RP, Capel AJ, Lewis MP, Silberschmidt VV, Li S (2019) Polydimethylsiloxane and poly (ether) ether ketone functionally graded composites for biomedical applications. J Mech Behav Biomed Mater 93:130–142. https://doi.org/10.1016/j.jmbbm.2019.02.012

Williams RJJ, Rozenberg BA, Pascault JP (1997) Reaction induced phase separation in modified thermosetting polymers. In: Polymer Analysis Polymer Physics. Adv Polym Sci, 128:95–156. https://doi.org/10.1007/3-540-61218-1_7

Vázquez-Torres H, Arcos-Casarrubias JA (2011) Preparation and characterization of an epoxy resin toughened with polydimethylsiloxane-glycidyl terminated. In: Macromex, XXIV Congr Nal Polím, SPM, Martínez-Richa A, Licea-Claveríe A, Zizumbo-López A (2011) Cancún, México, 434–438

Romo-Uribe A, Arcos-Casarrubias JA, Reyes-Mayer A, Guardian-Tapia R (2017) PDMS nanodomains in DGEBA epoxy induce high flexibility and toughness. Polym Plast Technol Eng 56:96–107. https://doi.org/10.1080/03602559.2016.1211691

Romo-Uribe A, Arcos-Casarrubias JA, Flores A, Valerio-Cárdenas C, González AE (2014) Influence of rubber on the curing kinetics of DGEBA epoxy and the effect on the morphology and hardness of the composites. Polym Bull 71:1241–1262. https://doi.org/10.1007/s00289-014-1121-6

Lipp ED (1991) Measurement of trace silanol in siloxanes by IR spectroscopy. Appl Spectrosc 45:477–483. https://doi.org/10.1366/0003702914337335

Chang MCO, Thomas A, Sperling LH (1987) Characterization of the area under loss modulus and tanδ –temperature curves: acrylic polymers and their sequential interpenetrating polymer networks. J Appl Polym Sci 34:409–422. https://doi.org/10.1002/app.1987.07030132

Jouyandeh M, Reza-Paran SM, Jannesari A, Reza-Saeb M (2019) ‘Cure Index’ for thermoset composites. Progr Org Coat 127:429–434. https://doi.org/10.1016/j.porgcoat.2018.11.025

Tudorachi N, Mustata F (2020) Curing and thermal degradation of diglycidyl ether of bisphenol A epoxy resin crosslinked with natural hydroxy acids as environmentally friendly hardeners. Arab J Chem 13:671–682. https://doi.org/10.1016/j.arabjc.2017.07.008

Lisardo Nuñez J, Taboada F, Fraga M, Núñez R (1997) Kinetic study and time–temperature–transformation cure diagram for an epoxy-diamine system. J Appl Polym Sci 66:1377–1388. https://doi.org/10.1002/(SICI)1097-4628(19971114)66:7%3c1377::AID-APP16%3e3.0.CO;2-%23

Vyazovkina S, Burnhamb AK, Criadoc JM, Pérez-Maquedac LA, Popescud C, Sbirrazzuoli N (2011) ICTAC Kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19. https://doi.org/10.1016/j.tca.2011.03.034

Alex AS, Rajeev RS, KrishnarajK SreenivasN, ManuSK GC, Sekkar V (2017) Thermal protection characteristics of polydimethylsiloxane-organoclay nanocomposite. Polym Degrad Stab 144:281–291. https://doi.org/10.1016/j.polymdegradstab.2017.08.026

Planes M, Le Coz C, Soum A, Carlotti S, Rejsek-RibaV LS, Remaury S, Solé S (2017) Polydimethylsiloxane/Additive Systems for thermal and ultraviolet stability in geostationary environment. J Spacecr Rockets 53:1128–1133. https://doi.org/10.2514/1.A33484

Pankaj SD (1986) A comparative study of different methods for the analysis of TGA curves. Comput Chem 10:293–297. https://doi.org/10.1016/0097-8485(86)85017-3

Yang G, Fu S-Y, Yang J-P (2007) Preparation and mechanical properties of modified epoxy resins with flexible diamines. Polymer 48:302–310. https://doi.org/10.1016/j.polymer.2006.11.031

Acknowledgement

Jorge Alberto Granados-Olvera was supported by a graduate scholarship from the Mexiquense Council for Science and Technology, COMECyT. We gratefully acknowledge the technical assistance of M. Sci. Atilano Gutiérrez Carrillo (Laboratorio de Resonancia Magnética Nuclear) for NMR measurements and Ing. Patricia Castillo Ocampo (Laboratorio de Microscopía Electrónica) for SEM and EDS X-ray measurements at Universidad Autónoma Metropolitana Campus Iztapalapa.

Funding

This work was supported by the Mexican Council for Science and Technology (CONACyT, Grant Number 2115-33428) and by the Tecnológico Nacional de México (Grant Number 656.18-PD: Obtención de resinas epoxídicas modificadas con elastómero nanoestructurado).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Arcos-Casarrubias, J.A., Vázquez-Torres, H., Granados-Olvera, J.A. et al. Viscoelastic behavior and toughness of the DGEBA epoxy resin with 1,2-diaminocyclohexane: effect of functionalized poly(dimethylsiloxane), diglycidyl ether, PDMS-DGE, pre-reacted with 1,2-diaminocyclohexane. Polym. Bull. 79, 2871–2901 (2022). https://doi.org/10.1007/s00289-021-03607-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03607-y