Abstract

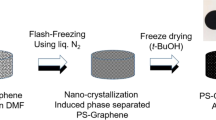

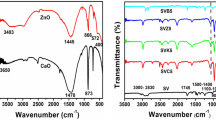

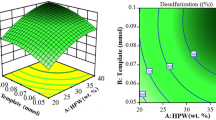

Herein, we report 3D-cross-linked polymer-2D-nanosheet composite networks for various organic solvents and crude oil spill cleanup. The 3D-cross-linked polystyrene-polymethyl methacrylate/divinyl benzene (PS-PMMA/DVB) with 2D-nanosheets of either boron nitride or commercial graphene (PS-PMMA/DVB-2D-nanosheets) composite absorbents has been successfully prepared by bulk polymerization technique. The effect of the crosslinker concentration (DVB), the 2D-nanosheets, and its weight ratio in the 3D-cross-linked polymer composite absorbents has been optimized based on the demonstrated absorption capacities for the oil and different organic solvents. The preparation of the 3D-cross-linked polymer composite absorbents has been carried out by the in situ one-step bulk polymerization method using styrene (S) and methyl methacrylate (MMA) monomers, crosslinker (DVB), the 2D-nanosheets, and AIBN as an initiator at 70 °C. The 3D-cross-linked composite absorbents were characterized by FT-IR, thermal, and mechanical analyses. The 3D-cross-linked PS-PMMA/DVB-2D-nanosheets absorbents have demonstrated excellent absorption capacities for both organic solvents and crude oil. The absorption kinetics for all the studied organic solvents and oil from the water was found to be pseudo-second-order kinetics. The thermodynamics of the absorption process indicates that the process is spontaneous and endothermic.

Graphic abstract

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

Chen J, Di Z, Shi J, Shu Y, Wan Z, Song L, Zhang W (2020) Marine oil spill pollution causes and governance: a case study of Sanchi tanker collision and explosion. J Clean Prod 273:122978

Magris RA, Giarrizzo T (2020) Mysterious oil spill in the Atlantic Ocean threatens marine biodiversity and local people in Brazil. Mar Pollut Bull 153:110961

DeBofsky A, Xie Y, Jardine TD, Hill JE, Jones PD, Giesy JP (2020) Effects of the husky oil spill on gut microbiota of native fishes in the North Saskatchewan River. Canada Aquat Toxicol 229:105658

Ferguson A, Solo-Gabriele H, Mena K (2020) Assessment for oil spill chemicals: current knowledge, data gaps, and uncertainties addressing human physical health risk. Mar Pollut Bull 150:110746

Asatekin A, Mayes AM (2009) Oil industry wastewater treatment with fouling resistant membranes containing amphiphilic comb copolymers. Environ Sci Technol 43:4487–4492. https://doi.org/10.1021/es803677k

Schrope M (2010) Deepwater horizon: a scientist at the centre of the spill. Nat News 466:680–684

Schrope M (2011) Oil spill: deep wounds Nat News 472:152–154

Ivshina IB, Kuyukina MS, Krivoruchko AV, Elkin AA, Makarov SO, Cunningham CJ, Peshkur TA, Atlas RM, Philp JC (2015) Oil spill problems and sustainable response strategies through new technologies. Environ Sci Process Impacts 17:1201–1219

Ilyas M, Ahmad W, Khan H, Yousaf S, Yasir M, Khan A (2019) Environmental and health impacts of industrial wastewater effluents in Pakistan: a review. Rev Environ Health 34:171–186

Johnston JE, Lim E, Roh H (2019) Impact of upstream oil extraction and environmental public health: a review of the evidence. Sci Total Environ 657:187–199

McNutt MK, Chu S, Lubchenco J, Hunter T, Dreyfus G, Murawski SA, Kennedy DM (2012) Applications of science and engineering to quantify and control the deepwater horizon oil spill. Proc Natl Acad Sci 109:20222–20228

Joye SB (2015) Deepwater horizon, 5 years on. Science 349:592–593

Deng D, Prendergast DP, MacFarlane J, Bagatin R, Stellacci F, Gschwend PM (2013) Hydrophobic meshes for oil spill recovery devices. ACS Appl Mater Interfaces 5:774–781. https://doi.org/10.1021/am302338x

Ono T, Sugimoto T, Shinkai S, Sada K (2007) Lipophilic polyelectrolyte gels as super-absorbent polymers for nonpolar organic solvents. Nat Mater 6:429

Yuan X, Chung TCM (2012) Novel solution to oil spill recovery: using thermodegradable polyolefin oil superabsorbent polymer (Oil–SAP). Energy Fuels 26:4896–4902. https://doi.org/10.1021/ef300388h

Adebajo MO, Frost RL, Kloprogge JT, Carmody O, Kokot S (2003) Porous materials for oil spill cleanup: a review of synthesis and absorbing properties. J Porous Mater 10:159–170

Zhou MH, Cho W-J (2003) Oil absorbents based on styrene–butadiene rubber. J Appl Polym Sci 89:1818–1824. https://doi.org/10.1002/app.12252

Ge J, Zhao H-Y, Zhu H-W, Huang J, Shi L-A, Yu S-H (2016) Advanced sorbents for oil-spill cleanup: recent advances and future perspectives. Adv Mater 28:10459–10490. https://doi.org/10.1002/adma.201601812

Saleem J, Adil Riaz M, Gordon M (2018) Oil sorbents from plastic wastes and polymers: a review. J Hazard Mater 341:424–437. https://doi.org/10.1016/j.jhazmat.2017.07.072

Deng J, Yang B, Chen C, Liang J (2015) Renewable eugenol-based polymeric oil-absorbent microspheres: preparation and oil absorption ability. ACS Sustain Chem Eng 3:599–605. https://doi.org/10.1021/sc500724e

Hozumi Y, Inaoka T, Gomi T, Goto T, Uno T, Rakutani K (1994) Oil-absorbent polymer and use therefor

Zhao J, Xiao C, Feng Y, Xu N (2013) A review: polymethacrylate fibers as oil absorbents. Polym Rev 53:527–545. https://doi.org/10.1080/15583724.2013.828749

Samitsu S, Zhang R, Peng X, Krishnan MR, Fujii Y, Ichinose I (2013) Flash freezing route to mesoporous polymer nanofibre networks. Nat Commun 4:2653. https://doi.org/10.1038/ncomms3653

Krishnan MR, Samitsu S, Fujii Y, Ichinose I (2014) Hydrophilic polymer nanofibre networks for rapid removal of aromatic compounds from water. Chem Commun 50:9393–9396. https://doi.org/10.1039/C4CC01786B

Kizil S, Sonmez HB (2020) One-pot fabrication of reusable hybrid sorbents for quick removal of oils from wastewater. J Environ Manag 261:109911

Haleem A, Li H-J, Li P-Y, Hu C-S, Li X-C, Wang J-Y, Chen S-Q, He W-D (2020) Rapid UV-radiation synthesis of polyacrylate cryogel oil-sorbents with adaptable structure and performance. Environ Res 187:109488

Zimmermann MVG, Zattera AJ, Fenner BR, Santana RMC (2020) Sorbent system based on organosilane-coated polyurethane foam for oil spill clean up. Polym Bull 1–18

Bhardwaj N, Bhaskarwar AN (2018) A review on sorbent devices for oil-spill control. Environ Pollut 243:1758–1771

Nam C, Li H, Zhang G, Lutz LR, Nazari B, Colby RH, Chung TM (2018) Practical oil spill recovery by a combination of polyolefin absorbent and mechanical skimmer. ACS Sustai Chem Eng 6:12036–12045

Krishnan MR, Aldawsari YF, Alsharaeh EH (2020) Three-dimensionally cross-linked styrene-methyl methacrylate-divinyl benzene terpolymer networks for organic solvents and crude oil absorption. J Appl Polym Sci. https://doi.org/10.1002/app.49942

Mao M, Xu H, Guo K-Y, Zhang J-W, Xia Q-Q, Zhang G-D, Zhao L, Gao J-F, Tang L-C (2020) Mechanically flexible, super-hydrophobic and flame-retardant hybrid nano-silica/graphene oxide wide ribbon decorated sponges for efficient oil/water separation and fire warning response. Composites Part A: Applied Science and Manufacturing; 140: 106191

Zhang J, Raza S, Wang P, Wen H, Zhu Z, Huang W, Mohamed IM, Liu C (2020) Polymer brush-grafted ZnO-modified cotton for efficient oil/water separation with abrasion/acid/alkali resistance and temperature “switch” property. J Colloid Interface Sci 580:822–833

Zhang N, Qi Y, Zhang Y, Luo J, Cui P, Jiang W (2020) A review on oil/water mixture separation material. Ind Eng Chem Res 59:14546–14568

Nam C, Zhang G, Chung TCM (2018) Polyolefin-based interpenetrating polymer network absorbent for crude oil entrapment and recovery in aqueous system. J Hazard Mater 351:285–292. https://doi.org/10.1016/j.jhazmat.2018.03.004

Nam C, Li H, Zhang G, Chung TCM (2016) Petrogel: new hydrocarbon (oil) absorbent based on polyolefin polymers. Macromolecules 49:5427–5437. https://doi.org/10.1021/acs.macromol.6b01244

Yang L, Bai B, Ding C, Wang H, Suo Y (2016) Synthesis and properties of the rapeseed meal-grafted-poly(methyl methacrylate-co-butyl acrylate) oil-absorbents. RSC Adv 6:9507–9517. https://doi.org/10.1039/C5RA24683K

Abirami AA, Kumar PS, Prakash DG, Ravirajan A, Umasankaran A, Narayanan P, Ravishankar K, Kumar CS, Nagaraju S, Reddy K (2020) Synthesis and application of porous oil-sorbent microspheres: characterization, retention capacity and sorption kinetics. Sep Purif Technol 234:116095

Alsharaeh EH, Faisal NH, Othman AA, Ahmed R (2013) Evaluation of nanomechanical properties of (styrene–methyl methacrylate) copolymer composites containing graphene sheets. Ind Eng Chem Res 52:17871–17881. https://doi.org/10.1021/ie402390j

Michael FM, Krishnan MR, AlSoughayer S, Busaleh A, Almohsin A, Alsharaeh EH (2020) Thermo-elastic and self-healing polyacrylamide -2D nanofiller composite hydrogels for water shutoff treatment. J Petrol Sci Eng 193:107391. https://doi.org/10.1016/j.petrol.2020.107391

Krishnan MR, Aldawsari Y, Michael FM, Li W, Alsharaeh EH (2021) Mechanically reinforced polystyrene-polymethyl methacrylate copolymer-graphene and Epoxy–Graphene composites dual-coated sand proppants for hydraulic fracture operations. J Petrol Sci Eng 196:107744. https://doi.org/10.1016/j.petrol.2020.107744

Michael FM, Krishnan MR, Li W, Alsharaeh EH (2020) A review on polymer-nanofiller composites in developing coated sand proppants for hydraulic fracturing. J Nat Gas Sci Eng 83:103553. https://doi.org/10.1016/j.jngse.2020.103553

Almohsin A, Michal F, Alsharaeh E, Bataweel M, Krishnan M (2019) Self-healing PAM composite hydrogel for water shutoff at high temperatures: thermal and rheological investigations. In: SPE-198664-MS. Society of Petroleum Engineers, Dubai, UAE, p 8

Krishnan M, Michal F, Alsoughayer S, Almohsin A, Alsharaeh E (2019) Thermodynamic and kinetic investigation of water absorption by PAM composite hydrogel. In: SPE-198033-MS. Society of Petroleum Engineers, Mishref, Kuwait, p 11

Keishnan MR, Michael FM, Almohsin AM, Alsharaeh EH (2020) Thermal and rheological investigations on N,N′-methylenebis acrylamide cross-linked polyacrylamide nanocomposite hydrogels for water shutoff applications. In: OTC-30123-MS. Offshore technology conference, OTC, p 9

Alsharaeh EH, Othman AA (2014) Microwave irradiation synthesis and characterization of RGO-AgNPs/polystyrene nanocomposites. Polym Compos 35:2318–2323

Bi H, Xie X, Yin K, Zhou Y, Wan S, He L, Xu F, Banhart F, Sun L, Ruoff RS (2012) Spongy graphene as a highly efficient and recyclable sorbent for oils and organic solvents. Adv Func Mater 22:4421–4425. https://doi.org/10.1002/adfm.201200888

Lei W, Portehault D, Liu D, Qin S, Chen Y (2013) Porous boron nitride nanosheets for effective water cleaning. Nat Commun 4:1777

Liu Z, Fang Y, Jia H, Wang C, Song Q, Li L, Lin J, Huang Y, Yu C, Tang C (2018) Novel multifunctional cheese-like 3D carbon-BN as a highly efficient adsorbent for water purification. Sci Rep 8:1104. https://doi.org/10.1038/s41598-018-19541-5

Rafiee MA, Narayanan TN, Hashim DP, Sakhavand N, Shahsavari R, Vajtai R, Ajayan PM (2013) Hexagonal boron nitride and graphite oxide reinforced multifunctional porous cement composites. Adv Func Mater 23:5624–5630. https://doi.org/10.1002/adfm.201203866

Yu Y, Chen H, Liu Y, Craig VSJ, Wang C, Li LH, Chen Y (2015) Superhydrophobic and superoleophilic porous boron nitride nanosheet/polyvinylidene fluoride composite material for oil-polluted water cleanup. Adv Mater Interfaces 2:1400267. https://doi.org/10.1002/admi.201400267

Liu D, He L, Lei W, Klika KD, Kong L, Chen Y (2015) Multifunctional polymer/porous boron nitride nanosheet membranes for superior trapping emulsified oils and organic molecules. Adv Mater Interfaces 2:1500228. https://doi.org/10.1002/admi.201500228

Wu C, Huang X, Wu X, Qian R, Jiang P (2013) Mechanically flexible and multifunctional polymer-based graphene foams for elastic conductors and oil-water separators. Adv Mater 25:5658–5662. https://doi.org/10.1002/adma.201302406

Periasamy AP, Wu W-P, Ravindranath R, Roy P, Lin G-L, Chang H-T (2017) Polymer/reduced graphene oxide functionalized sponges as superabsorbents for oil removal and recovery. Mar Pollut Bull 114:888–895. https://doi.org/10.1016/j.marpolbul.2016.11.005

Li H, Liu L, Yang F (2013) Covalent assembly of 3D graphene/polypyrrole foams for oil spill cleanup. J Mater Chem A 1:3446–3453. https://doi.org/10.1039/C3TA00166K

Wang M, Duan X, Xu Y, Duan X (2016) Functional three-dimensional graphene/polymer composites. ACS Nano 10:7231–7247. https://doi.org/10.1021/acsnano.6b03349

Meng W, Huang Y, Fu Y, Wang Z, Zhi C (2014) Polymer composites of boron nitride nanotubes and nanosheets. J Mater Chem C 2:10049–10061. https://doi.org/10.1039/C4TC01998A

Michael FM, Krishnan MR, Fathima A, Busaleh A, Almohsin A, Alsharaeh EH (2019) Zirconia/graphene nanocomposites effect on the enhancement of thermo-mechanical stability of polymer hydrogels. Mater Today Commun 21:100701. https://doi.org/10.1016/j.mtcomm.2019.100701

Krishnan MR, Lu K, Chiu W, Chen I, Lin J, Lo T, Georgopanos P, Avgeropoulos A, Lee M, Ho R (2018) Directed self-assembly of star-block copolymers by topographic nanopatterns through nucleation and growth mechanism. Small 14:1704005

Krishnan MR, Chien Y-C, Cheng C-F, Ho R-M (2017) Fabrication of mesoporous polystyrene films with controlled porosity and pore size by solvent annealing for templated syntheses. Langmuir 33:8428–8435

Zhu H, Qiu S, Jiang W, Wu D, Zhang C (2011) Evaluation of electrospun polyvinyl chloride/polystyrene fibers as sorbent materials for oil spill cleanup. Environ Sci Technol 45:4527–4531. https://doi.org/10.1021/es2002343

Shojaei N, Aminsharei F, Abbastabar Ahangar H (2020) Application of hydrophobic polymers as solidifiers for oil spill cleanup. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-020-02882-y

Rosales PI, Suidan MT, Venosa AD (2010) A laboratory screening study on the use of solidifiers as a response tool to remove crude oil slicks on seawater. Chemosphere 80:389–395. https://doi.org/10.1016/j.chemosphere.2010.04.036

Cui X, Shao H, Song Y, Yang S, Wang F, Liu H (2019) Preparation of highly interconnected porous polymer microbeads via suspension polymerization of high internal phase emulsions for fast removal of oil spillage from aqueous environments. RSC Adv 9:25730–25738

Weber M, Stadler R (1988) Hydrophilic-hydrophobic two-component polymer networks: 2. Synthesis and characterization of poly(ethylene oxide)-linked-polybutadiene. Polymer 29:1071–1078. https://doi.org/10.1016/0032-3861(88)90017-1

Ward IM, Sweeney J (2012) Mechanical properties of solid polymers. Wiley, Hoboken

V Bershtein V Egorov 1994 Differential scanning calorimetry of polymers: physics chemistry. Analysis, Technology 3

White CC, VanLandingham MR, Drzal PL, Chang N-K, Chang S-H (2005) Viscoelastic characterization of polymers using instrumented indentation. II. Dynamic testing*. J Polym Sci, Part B: Polym Phys 43:1812–1824. https://doi.org/10.1002/polb.20455

Fang P, Mao P, Chen J, Du Y, Hou X (2014) Synthesis and properties of a ternary polyacrylate copolymer resin for the absorption of oil spills. J Appl Polym Sci. https://doi.org/10.1002/app.40180

Li D, Zhu FZ, Li JY, Na P, Wang N (2013) Preparation and characterization of cellulose fibers from corn straw as natural oil sorbents. Ind Eng Chem Res 52:516–524. https://doi.org/10.1021/ie302288k

Lagergren S (1898) About the theory of so-called adsorption of soluble substances. Sven Vetenskapsakad Handingarl 24:1–39

Ho Y-S, McKay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465

Sidik SM, Jalil AA, Triwahyono S, Adam SH, Satar MAH, Hameed BH (2012) Modified oil palm leaves adsorbent with enhanced hydrophobicity for crude oil removal. Chem Eng J 203:9–18. https://doi.org/10.1016/j.cej.2012.06.132

Jaycock MJ, Parfitt GD (1981) Chemistry of interfaces. E. Horwood, Sawston

Mahmoodi NM, Arami M, Bahrami H, Khorramfar S (2010) Novel biosorbent (Canola hull): surface characterization and dye removal ability at different cationic dye concentrations. Desalination 264:134–142

Anirudhan TS, Rejeena SR (2013) Poly(methacrylic acid-co-vinyl sulfonic acid)-grafted-magnetite/nanocellulose superabsorbent composite for the selective recovery and separation of immunoglobulin from aqueous solutions. Sep Purif Technol 119:82–93. https://doi.org/10.1016/j.seppur.2013.08.019

Acknowledgements

This study is part of research project agreement no. AFU-01-2017 in collaboration with EXPEC advanced research center, Saudi Aramco. The authors gratefully acknowledge the continued support from AlFaisal University and its office of research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Krishnan, M.R., Aldawsari, Y.F. & Alsharaeh, E.H. 3D-poly(styrene-methyl methacrylate)/divinyl benzene-2D-nanosheet composite networks for organic solvents and crude oil spill cleanup. Polym. Bull. 79, 3779–3802 (2022). https://doi.org/10.1007/s00289-021-03565-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03565-5