Abstract

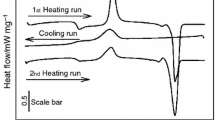

Biocomposites based on poly (caprolactone) (PCL) incorporating different contents of niobium pentoxide (Nb2O5) and alumina (Al2O3) were prepared in a laboratory internal mixer. The thermal properties, biodegradability and non-isothermal crystallization kinetics modeling of the composites were investigated. Crystallization kinetics were analyzed using the methods of Pseudo-Avrami and Mo models with cooling rates of 2, 4, 8 and 16 °C/min, and the results indicated that the models described well the non-isothermal crystallization kinetics of the tested samples. The addition of oxides leads to a slight increase in the thermal stability of the polymeric matrix, either with alumina or niobium pentoxide and regardless of concentration, delaying the degradation process. The melting temperature tends to remain constant regardless of the increase in the heating rate or content of niobium pentoxide or alumina present, indicating that the melting temperature does not appear to be affected by these parameters. The presence of the fillers accelerates the biodegradation of the PCL matrix in the composites and this effect becomes more evident with the increase in the filler content, and more for alumina than niobium pentoxide.

Similar content being viewed by others

Data availability

This work is the result of a doctoral work already completed. Data can be shared.

Code availability

Not applicable.

References

Santhanam A, Sasidharan S (2009) Microbial production of polyhydroxy alkanotes (PHA) from Alcaligens spp. and Pseudomonas oleovorans using different carbon sources. Afr J Biotechnol 9(21):3144–3150. https://doi.org/10.5897/AJB10.018

Wu C-S (2010) Preparation and characterizations of polycaprolactone/green coconut fiber composites. J Appl Polym Sci 115:948–956. https://doi.org/10.1002/app.30955

Wang XL, Huang FY, Zhou Y, Wang YZ (2008) Nonisothermal crystallization kinetics of poly(-caprolactone)/montmorillonite nanocomposites. J Macromol Sci B 48(4):710–722. https://doi.org/10.1080/00222340902959420

Sarasini F (2009) Thermoplastic biopolymer matrices for biocomposites. In: Ray D (ed) Biocomposites for high-performance applications, 1st edn. Woodhead Publishing, 81–123. https://doi.org/10.1016/B978-0-08-100793-8.00004-1

Mallakpour S, Dinari M (2013) Enhancement in thermal properties of poly(vinyl alcohol) nanocomposites reinforced with Al2O3 nanoparticles. J Reinf Plast Comp 32(4):217–224. https://doi.org/10.1177/0731684412467236

Ashok CH, Rao VK, Shilpa Chakra CH (2016) CuO/TiO2 metal oxide nanocomposite synthesis via room temperature ionic liquid. J Nanomater Mol Nanotechnol 5:1. https://doi.org/10.4172/2324-8777.1000178

Mallakpour S, Nouruzi N (2017) Polycaprolactone/metal oxide nanocomposites: an overview of recent progress and applications. In: Shimpi NG (ed) Biodegradable and Biocompatible Polymer Composites. Woodhead Publishing, Cambridge, UK, 223–263. https://doi.org/10.1016/B978-0-08-100970-3.02001-0

Mallakpour S, Javadpour M (2016) The potential use of recycled PET bottle in nanocomposites manufacturing with modified ZnO nanoparticles capped with citric acid: preparation, thermal, and morphological characterization. RSC Adv 6:15039–15047. https://doi.org/10.1039/C5RA27631D

Mallakpour S, Jarang N (2015) Exploration of the role of modified titania nanoparticles with citric acid and vitamin C in improvement of thermal stability, optical property, and mechanical behavior of novel poly(vinyl chloride) nanocomposite films. J Vinyl Addit Techn 23:1–10. https://doi.org/10.1002/vnl.21526

Mallakpour S, Khani Z (2016) Use of vitamin B1 for the surface treatment of silica (SiO2) and synthesis of poly(vinyl chloride)/SiO2 nanocomposites with advanced properties. Polym Bull 74:3579–3594. https://doi.org/10.1007/s00289-017-1911-8

Mallakpour S, Nezamzadeh Ezhieh A (2016) Polymer nanocomposites based on modified zro2 nps and poly(vinyl alcohol)/poly(vinyl pyrrolidone) blend: optical, morphological, and thermal properties. Polym Plast Technol Eng 56:1136–1145. https://doi.org/10.1080/03602559.2016.1253741

Mallakpour S, Abdolmaleki A, Rostami M (2014) Morphological and thermal properties of poly(amide-imide)/zno nanocomposites derived from 4,4′-methylenebis(3-chloro-2,6-diethyl trimellitimidobenzene) and 3,5-diamino-N-(4-hydroxyphenyl)benzamide. Polym Plast Technol Eng 53:1615–16240. https://doi.org/10.1080/03602559.2014.919644

Velten D, Eisenbarth E, Schanne N, Breme J (2009) Biocompatible Nb2O5 thin films prepared by means of the sol-gel process. J Mater Sci-Mater M 15:457–461. https://doi.org/10.1023/B:JMSM.0000021120.86985.f7

Karlinsey RL, Hara AT, Yi K, Duhn CW (2009) Bioactivity of novel self-assembled crystalline Nb2O5 microstructures in simulated and human salivas. Biomed Mater 1:16–23. https://doi.org/10.1088/1748-6041/1/1/003

Bergschmidt P, Bader R, Finze S et al (2011) Comparative study of clinical and radiological outcomes of unconstrained bicondylar total knee endoprostheses with anti-allergic coating. Open Orthop J 5:354–360. https://doi.org/10.2174/1874325001105010354

Milak PC, Minatto FD, De Noni A, Montedo ORK (2015) Wear performance of alumina-based ceramics-a review of the influence of microstructure on erosive wear. Cerâmica 61:88–103. https://doi.org/10.1590/0366-69132015613571871

Mazur M, Kalisz M, Wojcieszak D et al (2015) Determination of structural, mechanical and corrosion properties of Nb2O5 and (NbyCu1 - Y)Ox thin films deposited on Ti6Al4V alloy substrates for dental implant applications. Mat Sci Eng C 47:211–221. https://doi.org/10.1016/j.msec.2014.11.047

Díez-Pascual A, Díez-Vicente A (2014) Poly(3-hydroxybutyrate)/ZnO bionanocomposites with improved mechanical, barrier and antibacterial properties. Int J Mol Sci 15:10950–10973. https://doi.org/10.3390/ijms150610950

Yu W, Lan CH, Wang SJ et al (2010) Influence of zinc oxide nanoparticles on the crystallization behavior of electrospun poly(3-hydroxybutyrate-co-3-hydroxyvalerate) nanofibers. Polymer 51:2403–2409. https://doi.org/10.1016/j.polymer.2010.03.024

Hernández Battez A, González R, Viesca JL et al (2009) CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants. Wear 265:422–428. https://doi.org/10.1016/j.wear.2007.11.013

Chen P, Zhou H, Liu W et al (2015) The synergistic effect of zinc oxide and phenylphosphonic acid zinc salt on the crystallization behavior of poly (lactic acid). Polym Degrad Stabil 122:25–35. https://doi.org/10.1016/j.polymdegradstab.2015.10.014

Xu G, Du L, Wang H et al (2008) Nonisothermal crystallization kinetics and thermomechanical properties of multiwalled carbon nanotube-reinforced poly(ε-caprolactone) composites. Polym Int 57:1052–1066. https://doi.org/10.1002/pi.2448

Ahmed J, Luciano G, Schizzi I et al (2018) Non-isothermal crystallization behavior, rheological properties and morphology of poly(ε-caprolactone)/graphene oxide nanosheets composite films. Thermochim Acta 659:96–104. https://doi.org/10.1016/j.tca.2017.11.009

Pires LSO, Fernandes MHFV, de Oliveira JMM (2018) Crystallization kinetics of PCL and PCL–glass composites for additive manufacturing. J Therm Anal Calorim. https://doi.org/10.1007/s10973-018-7307-7

Schäfer H, Reul LTA, Souza FM et al (2020) Crystallization behavior of polycaprolactone/babassu compounds. J Therm Anal Calorim. https://doi.org/10.1007/s10973-020-09433-0

Mahalakshmi S, Parthasarathy V, Tung KL et al (2019) Non-isothermal crystallization and degradation kinetics of Fe3 O4–thymolblue functionalized poly(ε-caprolactone). J Polym Environ 27:1259–1272. https://doi.org/10.1007/s10924-019-01401-6

Perstorp, CAPATM 6500 product data sheet. Available at: < https://www.tri-iso.com/documents/perstorp_capa_6500_PDS.pdf>. Accessed 19 April 2019

Sousa JC, Costa ARM, Lima JC et al (2019) Polycaprolactone (PCL)/alumina and PCL/niobium pentoxide composites: rheology, crystallization, and mechanical properties. Polym Compos. https://doi.org/10.1002/pc.25452

Lima JC, Sousa JC, Arruda SA et al (2018) Polycaprolactone matrix composites reinforced with brown coir: rheological, crystallization, and mechanical behavior. Polym Compos 40:1–9. https://doi.org/10.1002/pc.24951

Alves TS, Silva Neto JE, Silva SML et al (2016) Process simulation of laboratory internal mixers. Polym Test 50:94–100. https://doi.org/10.1016/j.polymertesting.2016.01.002

Costa ARM, Almeida TG, Silva SML et al (2015) Chain extension in poly(butylene-adipate-terephthalate). Inline testing in a laboratory internal mixer. Polym Test 42:115–121. https://doi.org/10.1016/j.polymertesting.2015.01.007

Patki R, Mezghani K, Phillips PJ (2007) Crystallization kinetics of polymers. In: Mark JE (ed) Physical properties of polymers handbook 2nd. ed. Springer, Berlin: Springer, 625–640. https://doi.org/10.1021/ja0769503

Van KrevelenTeNijenhuis DWK (2009) Properties of Polymers. Elsevier, Amsterdam. https://doi.org/10.1016/B978-0-08-054819-7.X0001-5

Jeziorny A (1978) Parameters characterizing the kinetics of the non-isothermal crystallization of poly(ethylene terephthalate) determined by d.s.c. Polymer 19:1142–1144. https://doi.org/10.1016/0032-3861(78)90060-5

An Y, Dong L, Mo Z et al (1998) Nonisothermal crystallization kinetics of poly(β-hydroxybutyrate). J Polym Sci Pol Phys 36:305–1312. https://doi.org/10.1002/(SICI)1099-0488(199806)36:8%3c1305::AIDPOLB5%3e3.0.CO;2-Q

Liu T, Mo Z, Wang S, Zhang H (1997) Nonisothermal melt and cold crystallization kinetics of poly(Aryl Ether Ether Ketone Ketone). Polym Eng Sci 37:568–575. https://doi.org/10.1002/pen.11700

Liu T, Mo Z, Zhang H (1998) Nonisothermal crystallization behavior of a novel poly(aryl ether ketone): PEDEKmK. J Appl Polym Sci 67:815–821. https://doi.org/10.1002/(SICI)1097-4628(19980131)67:5%3c815::AIDAPP6%3e3.0.CO;2-W

American society for testing and materials - ASTM (2004) ASTM G160-03: standard pratice for evaluating microbial susceptibility of nonmetallic materials by laboratory soil burial. Vol 14.04. ASTM, West Conshohocken

Marques OM, Lima MAG, Palha MAPAS (2013) Práticas de microbiologia. UFPE, Recife

Khandanlou R, Ahmad MB, Shameli K et al (2014) Mechanical and thermal stability properties of modified rice straw fiber blend with polycaprolactone composite. J Nanomater 2014:1–9. https://doi.org/10.1155/2014/675258

Bulatovic VO, Bajsic EG, Filipan V, et al (2014) (PDF) Thermal degradation of pcl and pcl/ micro and nano composites. In: Matrib. https://www.researchgate.net/publication/267924632_THERMAL_DEGRADATION_OF_PCL_AND_PCL_MICRO_AND_NANO_COMPOSITES. Accessed 12 Nov 2020

Fukushima K, Tabuani D, Abbate C et al (2011) Preparation, characterization and biodegradation of biopolymer nanocomposites based on fumed silica. Eur Polym J 47:139–152. https://doi.org/10.1016/j.eurpolymj.2010.10.027

Vitorino MBC, Cipriano PB, Wellen RMR et al (2016) Nonisothermal melt crystallization of PHB/babassu compounds: kinetics of crystallization. J Therm Anal Calorim 126:755–769. https://doi.org/10.1007/s10973-016-5514-7

Wu T-M, Chen E-C (2006) Isothermal and nonisothermal crystallization kinetics of poly(ɛ-caprolactone)/multi-walled carbon nanotube composites. Polym Eng Sci 46:1309–1317. https://doi.org/10.1002/pen.20620

Hua L, Kai WH, Inoue Y (2007) Crystallization behavior of poly(ϵ-caprolactone)/graphite oxide composites. J Appl Polym Sci 106:4225–4232. https://doi.org/10.1002/app.26976

Chen J, Wu D, Tam KC et al (2017) Effect of surface modification of cellulose nanocrystal on nonisothermal crystallization of poly(β-hydroxybutyrate) composites. Carbohydr Polym 157:1821–1829. https://doi.org/10.1016/j.carbpol.2016.11.071

Liu Q, Deng B, Zhu M et al (2011) Nonisothermal crystallization kinetics of poly( ϵ-caprolactone)/zinc oxide nanocomposites with high zinc oxide content. J Macromol Sci B 50(12):2366–2375. https://doi.org/10.1080/00222348.2011.623999

Yang Z, Peng H, Wang W, Liu T (2010) Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J Appl Polym Sci. https://doi.org/10.1002/app.31787

Di Lorenzo ML, Silvestre C (1999) Non-isothermal crystallization of polymers. Prog Polym Sci 24:917–950. https://doi.org/10.1016/S0079-6700(99)00019-2

Ando H, Kawasaki N, Yamano N et al (2015) Biodegradation of a poly(ε-caprolactone-co-l-lactide)-visible-light-sensitive TiO2 composite with an on/off biodegradation function. Polym Degrad Stabil 114:65–71. https://doi.org/10.1016/j.polymdegradstab.2015.02.003

Augustine R, Kalarikkal N, Thomas S (2016) Effect of zinc oxide nanoparticles on the in vitro degradation of electrospun polycaprolactone membranes in simulated body fluid. J Polym Biomater 65:28–37. https://doi.org/10.1080/00914037.2015.1055628

Lefèvre C, Tidjani A, Vander Wauven C, David C (2002) The interaction mechanism between microorganisms and substrate in the biodegradation of polycaprolactone. J Appl Polym Sci 83:1334–1340. https://doi.org/10.1002/app.10124

Li F, Yu D, Lin X et al (2012) Biodegradation of poly(ε-caprolactone) (PCL) by a new penicillium oxalicum strain DSYD05-1. World J Microb Biot 28:2929–2935. https://doi.org/10.1007/s11274-012-1103-5

Lanfranconi MR, Alvarez VA, LLN, (2018) Non-isothermal crystallization of PCL/CLAY nanocomposites. Adv Mater Lett 9:1. https://doi.org/10.5185/amlett.2018.1976

Gonçalves SPC, Martins-Franchetti SM (2010) Action of soil microorganisms on PCL and PHBV blend and films. J Polym Environ 18:714–719. https://doi.org/10.1007/s10924-010-0209-9

Campos A, Marconato JC, Franchetti SMM (2009) Biodegradação de filmes de PP/PCL em solo e solo com chorume. Polímeros 20:295–300. https://doi.org/10.1590/S0104-14282010005000039

Acknowledgements

The authors thank Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq—Brazil), Grant Numbers: 130496/2015-4 and 306574/2018-7 and Fundação de Amparo à Ciência e Tecnologia do Estado de Pernambuco (FACEPE—Brazil), Grant Numbers: IBPG-1479-3.06/16, IBPG-0699-3.06/15 and BFP-0158-3.06/18 for financial support. We also thank Eduardo Luis Canedo (†) for his substantial contribution to research design and interpretation of data.

Funding

This reseach was supported by Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq—Brazil), and Fundação de Amparo à Ciência e Tecnologia do Estado de Pernambuco (FACEPE–Brazil).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sousa, J.C., Costa, A.R.M., Lima, J.C. et al. Crystallization kinetics modeling, thermal properties and biodegradability of poly (ε-caprolactone)/niobium pentoxide and alumina compounds. Polym. Bull. 78, 7337–7353 (2021). https://doi.org/10.1007/s00289-020-03468-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03468-x