Abstract

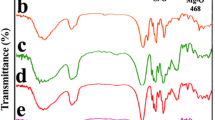

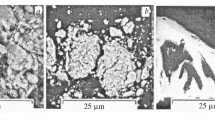

The surface mineral modification of montmorillonite (Mt) layers was carried out by removing some of the exchangeable cations and anions (salts) using dimethylformamide as a chelating agent. The rest unremoved exchangeable cations were balanced by the permanent negative charges in the Mt layers. The modified Mt layers were characterized by X-ray fluorescence, high-resolution scanning electron microscopy (HR-SEM), dynamic light scattering (DLS), and high-resolution transmission electron microscopy. The completely exfoliated modified Mt layers were composed of polyethylcyanoacrylate (PECA) at different ratios 1, 3, 5, 7, 10, and 15% (wt/wt). The obtained composites were investigated by molar mass, FTIR, small-angle X-ray diffraction, wide-angle X-ray diffraction, HR-SEM, DLS, and TGA. The results showed that the exchangeable cations and anions (salts) were removed from the surfaces of Mt layers, and all the percentages of loaded Mt layers were completely exfoliated in the bulk of PECA. TEM morphology exhibited clearly separated modified Mt layers due to removing the salts. SEM morphology showed highly exfoliated modified Mt layers in PECA bulk. TGA and nanoindentation data were showed increases in both thermal stability and mechanical properties of prepared composites by increasing the ratios of modified Mt layers in the bulk of PECA.

Similar content being viewed by others

References

Yarahmadi N, Jakubowicz I, Hjertberg T (2010) Development of poly(vinyl chloride)/montmorillonite nanocomposites using chelating agents. Polym Degrad Stab 95(2):132–137. https://doi.org/10.1016/j.polymdegradstab.2009.11.043

Morgan AB, Gilman JW (2003) Characterization of polymer-layered silicate (clay) nanocomposites by transmission electron microscopy and X-ray diffraction: a comparative study. J Appl Polym Sci 87(8):1329–1338

Liff SM, Kumar N, McKinley GH (2007) High-performance elastomeric nanocomposites via solvent-exchange processing. Nat Mater 6(1):76–83. https://doi.org/10.1038/nmat1798

Metwally SS, Ayoub RR (2016) Modification of natural bentonite using a chelating agent for sorption of 60Co radionuclide from aqueous solution. Appl Clay Sci 126:33–40. https://doi.org/10.1016/j.clay.2016.02.021

Petersen H, Jakubowicz I, Enebro J, Yarahmadi N (2015) Organic modification of montmorillonite for application in plasticized PVC nanocomposites. Appl Clay Sci 107:78–84. https://doi.org/10.1016/j.clay.2015.01.006

Shen Y, Yu X, Wang Y (2019) Facile synthesis of modified rectorite (M-REC) for effective removal of anionic dye from water. J Mol Liq 278:12–18. https://doi.org/10.1016/j.molliq.2019.01.045

Santos TT, Almeida TG, Morais DDS, Magalhães FD, Guedes RM, Canedo EL, Carvalho LH (2019) Effect of filler type on properties of PBAT/organoclay nanocomposites. Polym Bull 77(2):901–917. https://doi.org/10.1007/s00289-019-02778-z

Takahashi K, Ishii R, Nakamura T, Suzuki A, Ebina T, Yoshida M, Kubota M, Nge TT, Yamada T (2017) Flexible electronic substrate film fabricated using natural clay and wood components with cross-linking polymer. Adv Mater 29(17):1606512. https://doi.org/10.1002/adma.201606512

Júnior LPC, Silva DBDS, de Aguiar MF, de Melo CP, Alves KG (2019) Preparation and characterization of polypyrrole/organophilic montmorillonite nanofibers obtained by electrospinning. J Mol Liq 275:452–462. https://doi.org/10.1016/j.molliq.2018.11.084

Silva DBDS, Júnior LP, de Aguiar MF, de Melo CP, Alves KG (2018) Preparation and characterization of nanofibers of polyvinyl alcohol/polyaniline-montmorillonite clay. J Mol Liq 272:1070–1076. https://doi.org/10.1016/j.molliq.2018.10.087

Gong F, Feng M, Zhao C, Zhang S, Yang M (2004) Thermal properties of poly (vinyl chloride)/montmorillonite nanocomposites. Polym Degrad Stab 84(2):289–294

Tajbakhsh M, Bazzar M, Ramzanian SF, Tajbakhsh M (2014) Sulfonated nanoClay minerals as a recyclable eco-friendly catalyst for the synthesis of quinoxaline derivatives in green media. Appl Clay Sci 88–89:178–185. https://doi.org/10.1016/j.clay.2013.12.023

Yalcinkaya F, Yalcinkaya B, Jirsak O (2015) Influence of salts on electrospinning of aqueous and nonaqueous polymer solutions. Journal of Nanomaterials 2015:1–12. https://doi.org/10.1155/2015/134251

Phadke MA, Kulkarni SS, Karode SK, Musale DA (2005) Poly (acrylonitrile) ultrafiltration membranes II Membrane morphology and permeation characteristics. J PolymSci Part B: Polym Phys 43(15):2074–2085. https://doi.org/10.1002/polb.20494

Qiao H, Cai Y, Chen F, Wei Q, Weng F, Huang F, Song L, Hu Y, Gao W (2010) Influences of organic-modified Fe-montmorillonite on structure, morphology and properties of polyacrylonitrile nanocomposite fibers. Fibers Polym 10(6):750–755. https://doi.org/10.1007/s12221-009-0750-0

Tatiana Ș, Ryan B, Ivanković A, Murphy N (2020) Dynamic mechanical analysis of carbon black filled, elastomer-toughened ethyl cyanoacrylate adhesive bulk films. Int J Adhes Adhes 101:102630. https://doi.org/10.1016/j.ijadhadh.2020.102630

Luo Z, Liu K, Guo M, Lian Z, Yan H, Wei W, Zhang B (2017) Modification of ethyl 2-cyanoacrylate using silica and nitrile butadiene rubber to achieve high thixotropy and low internal stress. J Adhes Sci Technol 32(10):1128–1141. https://doi.org/10.1080/01694243.2017.1400801

Xu J, Zhang L, Chen G (2013) Fabrication of graphene/poly(ethyl 2-cyanoacrylate) composite electrode for amperometric detection in capillary electrophoresis. Sens Actuators B: Chem 182:689–695. https://doi.org/10.1016/j.snb.2013.03.109

Hansen EL, Hemmen H, Fonseca DM, Coutant C, Knudsen KD, Plivelic TS, Bonn D, Fossum JO (2012) Swelling transition of a clay induced by heating. Sci Rep 2:618. https://doi.org/10.1038/srep00618

Wang Q, Mynar JL, Yoshida M, Lee E, Lee M, Okuro K, Kinbara K, Aida T (2010) High-water-content mouldable hydrogels by mixing clay and a dendritic molecular binder. Nature 463(7279):339–343. https://doi.org/10.1038/nature08693

Zhuang G, Zhang Z, Guo J, Liao L, Zhao J (2015) A new ball milling method to produce organo-montmorillonite from anionic and nonionic surfactants. Appl Clay Sci 104:18–26. https://doi.org/10.1016/j.clay.2014.11.023

Schoonheydt RA, Johnston CT, Bergaya F (2018) Clay Miner Surf 9:1–21. https://doi.org/10.1016/b978-0-08-102432-4.00001-9

Cheng K, Heidari Z (2018) A new method for quantifying cation exchange capacity in clay minerals. Appl Clay Sci 161:444–455. https://doi.org/10.1016/j.clay.2018.05.006

Shi J, Liu H, Lou Z, Zhang Y, Meng Y, Zeng Q, Yang M (2013) Effect of interlayer counterions on the structures of dry montmorillonites with Si4+/Al3+ substitution. Comput Mater Sci 69:95–99. https://doi.org/10.1016/j.commatsci.2012.11.019

Misra RDK, Yuan Q, Chen J, Yang Y (2010) Hierarchical structures and phase nucleation and growth during pressure-induced crystallization of polypropylene containing dispersion of nanoclay: the impact on physical and mechanical properties. Mater Sci Eng, A 527(9):2163–2181. https://doi.org/10.1016/j.msea.2009.11.023

Zawrah M, Khattab R, Saad E, Gado R (2014) Effect of surfactant types and their concentration on the structural characteristics of nanoclay. Spectrochim Acta Part A Mol Biomol Spectrosc 122:616–623

Wu LM, Tong DS, Zhao LZ, Yu WH, Zhou CH, Wang H (2014) Fourier transform infrared spectroscopy analysis for hydrothermal transformation of microcrystalline cellulose on montmorillonite. Appl Clay Sci 95:74–82

Madejová J (2003) FTIR techniques in clay mineral studies. Vib Spectrosc 31(1):1–10

Tas AC (2012) Calcium metal to synthesize amorphous or cryptocrystalline calcium phosphates. Mater Sci Eng, C 32(5):1097–1106. https://doi.org/10.1016/j.msec.2012.01.024

Gunasekaran S, Anbalagan G, Pandi S (2006) Raman and infrared spectra of carbonates of calcite structure. J Raman Spectrosc 37(9):892–899. https://doi.org/10.1002/jrs.1518

Ma Y, Zhu J, He H, Yuan P, Shen W, Liu D (2010) Infrared investigation of organo-montmorillonites prepared from different surfactants. Spectrochim Acta Part A Mol Biomol Spectrosc 76(2):122–129

Bounabi L, Mokhnachi NB, Haddadine N, Ouazib F, Barille R (2016) Development of poly(2-hydroxyethyl methacrylate)/clay composites as drug delivery systems of paracetamol. J Drug Deliv Sci Technol 33:58–65. https://doi.org/10.1016/j.jddst.2016.03.010

Ma L, Zhu J, He H, Xi Y, Zhu R, Tao Q, Liu D (2015) Thermal analysis evidence for the location of zwitterionic surfactant on clay minerals. Appl Clay Sci 112–113:62–67. https://doi.org/10.1016/j.clay.2015.04.021

Derakhshani E, Naghizadeh A (2018) Optimization of humic acid removal by adsorption onto bentonite and montmorillonite nanoparticles. J Mol Liq 259:76–81. https://doi.org/10.1016/j.molliq.2018.03.014

Bandyopadhyay J, Sinha Ray S (2010) The quantitative analysis of nano-clay dispersion in polymer nanocomposites by small angle X-ray scattering combined with electron microscopy. Polymer 51(6):1437–1449. https://doi.org/10.1016/j.polymer.2010.01.029

Carli LN, Bianchi O, Machado G, Crespo JS, Mauler RS (2013) Morphological and structural characterization of PHBV/organoclay nanocomposites by small angle X-ray scattering. Mater Sci Eng C Mater Biol Appl 33(2):932–937. https://doi.org/10.1016/j.msec.2012.11.023

Yu WH, Ren QQ, Tong DS, Zhou CH, Wang H (2014) Clean production of CTAB-montmorillonite: formation mechanism and swelling behavior in xylene. Appl Clay Sci 97–98:222–234. https://doi.org/10.1016/j.clay.2014.06.007

Zhirong L, Azhar Uddin M, Zhanxue S (2011) FT-IR and XRD analysis of natural Na-bentonite and Cu(II)-loaded Na-bentonite. Spectrochim Acta A Mol Biomol Spectrosc 79(5):1013–1016. https://doi.org/10.1016/j.saa.2011.04.013

Di Gianni A, Amerio E, Monticelli O, Bongiovanni R (2008) Preparation of polymer/clay mineral nanocomposites via dispersion of silylated montmorillonite in a UV curable epoxy matrix. Appl Clay Sci 42(1–2):116–124. https://doi.org/10.1016/j.clay.2007.12.011

Chonkaew W, Sombatsompop N, Brostow W (2013) High impact strength and low wear of epoxy modified by a combination of liquid carboxyl terminated poly(butadiene-co-acrylonitrile) rubber and organoclay. Eur Polym J 49(6):1461–1470. https://doi.org/10.1016/j.eurpolymj.2013.03.022

Zhu J, Zhu L, Zhu R, Tian S, Li J (2009) Surface microtopography of surfactant modified montmorillonite. Appl Clay Sci 45(1–2):70–75. https://doi.org/10.1016/j.clay.2009.04.010

Liu D, Yuan P, Liu H, Li T, Tan D, Yuan W, He H (2013) High-pressure adsorption of methane on montmorillonite, kaolinite and illite. Appl Clay Sci 85:25–30. https://doi.org/10.1016/j.clay.2013.09.009

Sani HA, Ahmad MB, Hussein MZ, Ibrahim NA, Musa A, Saleh TA (2017) Nanocomposite of ZnO with montmorillonite for removal of lead and copper ions from aqueous solutions. Process Saf Environ Prot 109:97–105. https://doi.org/10.1016/j.psep.2017.03.024

Wang G, Hua Y, Su X, Komarneni S, Ma S, Wang Y (2016) Cr(VI) adsorption by montmorillonite nanocomposites. Appl Clay Sci 124–125:111–118. https://doi.org/10.1016/j.clay.2016.02.008

Ryu J, Jang YJ, Choi S, Kang HJ, Park H, Lee JS, Park S (2016) All-in-one synthesis of mesoporous silicon nanosheets from natural clay and their applicability to hydrogen evolution. NPG Asia Mater 8(3):e248. https://doi.org/10.1038/am.2016.35

Hu Z, Zhang P, Xie R, Li M, Lu Z, Xu X, Song L, Zhou L, Wu Y, Chen M, Zhao X (2018) Controlled synthesis of train-structured montmorillonite/layered double hydroxide nanocomposites by regulating the hydrolysis of polylactic acid. J Mater Sci 53(23):15859–15870. https://doi.org/10.1007/s10853-018-2758-6

El Bourakadi K, Merghoub N, Fardioui M, Mekhzoum MEM, Kadmiri IM, Essassi EM, Bouhfid R (2019) Chitosan/polyvinyl alcohol/thiabendazoluim-montmorillonite bio-nanocomposite films: mechanical, morphological and antimicrobial properties. Compos Part B: Eng 172:103–110. https://doi.org/10.1016/j.compositesb.2019.05.042

Arranz-Andrés J, Pérez E, Cerrada ML (2012) Smectic polyester/layered silicate nanostructured hybrids: effect of modified nanoclay in the phase transitions. Polymer 53(2):386–394. https://doi.org/10.1016/j.polymer.2011.11.042

Zhu TT, Zhou CH, Kabwe FB, Wu QQ, Li CS, Zhang JR (2019) Exfoliation of montmorillonite and related properties of clay/polymer nanocomposites. Appl Clay Sci 169:48–66. https://doi.org/10.1016/j.clay.2018.12.006

da Silva Ribeiro SP, dos Santos Cescon L, Ribeiro RQCR, Landesmann A, de Moura Estevão LR, Nascimento RSV (2018) Effect of clay minerals structure on the polymer flame retardancy intumescent process. Appl Clay Sci 161:301–309. https://doi.org/10.1016/j.clay.2018.04.037

Zheng JP, Luan L, Wang HY, Xi LF, Yao KD (2007) Study on ibuprofen/montmorillonite intercalation composites as drug release system. Appl Clay Sci 36(4):297–301. https://doi.org/10.1016/j.clay.2007.01.012

Reguieg F, Ricci L, Bouyacoub N, Belbachir M, Bertoldo M (2019) Thermal characterization by DSC and TGA analyses of PVA hydrogels with organic and sodium MMT. Polym Bull 77(2):929–948. https://doi.org/10.1007/s00289-019-02782-3

Shaw AV, Vaughan AS, Andritsch T (2019) The effect of organoclay loading and matrix morphology on charge transport and dielectric breakdown in an ethylene-based polymer blend. J Mater Sci 54(19):13017–13028. https://doi.org/10.1007/s10853-019-03765-5

Abbasian M, Seyyedi M, Jaymand M (2019) Modification of thermoplastic polyurethane through the grafting of well-defined polystyrene and preparation of its polymer/clay nanocomposite. Polym Bull 77(3):1107–1120. https://doi.org/10.1007/s00289-019-02773-4

Das K, Ray D, Banerjee C, Bandyopadhyay NR, Mohanty AK, Misra M (2011) Novel materials from unsaturated polyester resin/styrene/tung oil blends with high impact strengths and enhanced mechanical properties. J Appl Polym Sci 119(4):2174–2182. https://doi.org/10.1002/app.32957

Tiwari A (2012) Nanomechanical analysis of hybrid silicones and hybrid epoxy coatings—a brief review. Adv Chem Eng Sci 02(01):34–44. https://doi.org/10.4236/aces.2012.21005

Libanori R, Erb RM, Reiser A, Le Ferrand H, Suess MJ, Spolenak R, Studart AR (2012) Stretchable heterogeneous composites with extreme mechanical gradients. Nat commun 3:1265. https://doi.org/10.1038/ncomms2281

He S, He T, Wang J, Wu X, Xue Y, Zhang L, Lin J (2019) A novel method to prepare acrylonitrile-butadiene rubber/clay nanocomposites by compounding with clay gel. Compos B Eng 167:356–361. https://doi.org/10.1016/j.compositesb.2019.03.013

Chen S, Xie J, Yang Z (2019) Effect of reactive montmorillonite with amino on the properties of polyimide/montmorillonite nanocomposite. Polym Bull 77(2):687–699. https://doi.org/10.1007/s00289-019-02767-2

Guillonneau G, Kermouche G, Bec S, Loubet J-L (2012) Determination of mechanical properties by nanoindentation independently of indentation depth measurement. J Mater Res 27(19):2551–2560. https://doi.org/10.1557/jmr.2012.261

Acknowledgements

The authors acknowledge the Egyptian Petroleum Research Institute for supporting us with suitable analyses.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fekry, M., Mazrouaa, A., Mohamed, M.G. et al. Properties of polyethylcyanoacrylate/modified Mt composites with highly exfoliated montmorillonite. Polym. Bull. 78, 5685–5711 (2021). https://doi.org/10.1007/s00289-020-03402-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03402-1