Abstract

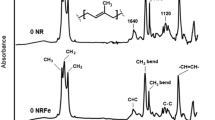

In harsh environments such as high altitude areas, the durability of rubber waterstops is a big concern. A long period of sunshine and the accompanying strong ultraviolet (UV) radiation accelerate the photooxidation and thermal oxygen aging of rubber waterstops, resulting in cracks, peeling off and even failure of waterstops. This study aims to investigate the performance of a widely used waterstop in simulated high altitude areas of western China by placing rubber waterstops in an UV aging chamber for 18, 36, 54, and 72 days. Mechanical properties, such as tensile strength, elongation, tear strength, compression set, and hardness, were measured. Moreover, scanning electron microscopy with X-ray microanalysis (SEM-EDS) and Fourier infrared spectroscopy-attenuated total reflection (FTIR-ATR) detection were performed on the damaged specimens to dissect the underlying mechanisms of deterioration in mechanical properties. The results showed that all the investigated mechanical properties of the rubber waterstop deteriorated with the increase in aging time. The increase in the UV aging time increased the surface cracks, decreased the unsaturated bonds, and increased the oxygen content and oxygen-containing functional groups of the rubber waterstop. It can also be found that the additive particles in the matrix gradually aggregated, and concurrently the carbon black particles decreased, which weakened the three-dimensionality of the cross section of the specimen. Findings from this paper provide new insights into the durability of rubber waterstops in high altitude areas.

Similar content being viewed by others

References

Hang LQ (2018) Application of waterstop in water conservancy engineering. Hebei Water Resour 5:41 (in Chinese)

Zhang LB (2012) Talking about the application of rubber waterstop in hydraulic engineering. Technol Enterp 9:241

Ma NN (2014) Damping performance and life prediction of nitrile rubber after aging. Dissertation, Qingdao University of Science and Technology

Li A (2009) Aging phenomenon of rubber and its aging mechanism. Spec Purp Rubber Prod 30(5):56–67

Zhang LP, Li H, Liu YP, Sun Y (2009) Research status and development trend of rubber material aging test. China Elastom 19(4):60–63

Wang HR, Li H, Sun Y, Liu YP (2013) Research status and development trend of rubber material aging test. Equip Environ Eng 4:66–70

Xiao Y (2006) Thermal oxidation aging of natural rubber vulcanizates. Dissertation, Northwestern Polytechnical University

Yang ZQ (1997) Modern vulcanized rubber technology, 1st edn. Petrochemical Press, Beijing

Xiong X (1996) Prediction of storage life of vulcanized rubber sealing materials. Aerosp Mater Technol 2:83–86

Zhang K, Huang YH, Ma Y, Zhou DH (2004) Rubber material accelerated aging test and life prediction method. Chem Propellants Polym Mater 2(6):44–48

Li X, Chen YL, Hou BB (2013) Research on the service life detection method of rubber waterstop. Spec Purp Rubber 34(03):60–61+65

Li YH, Li YM, Zhang XT (2017) Life prediction of large strain rubber waterstop used in Urumqi Metro. Spec Purp Rubber 05:66–70

Jiang H, Ji GL, Shi SB, Bi GY, Han F (1998) Characteristics of ultraviolet radiation in the northern Tibetan Plateau. Acta Energias Solaris Sinica 1:7–12

GB/T 18173.2-2014 (2014) Petroleum and chemical industry association of China, Polymer water-proof materials-Part2: waterstop. Chinese Code Press, Beijing (in Chinese)

GB/T 16585–1996 (1996) Ministry of Chemical Industry of China, rubber, vulcanized-test method of resistance to artificial weathering (fluorescent UV lamp). Chinese Code Press, Beijing (in Chinese)

GB/T 528–2009 (2009) Petroleum and chemical industry association of China, rubber, vulcanized or thermoplastic-determination of tensile stress-strain properties. Chinese Code Press, Beijing (in Chinese)

GB/T 529–2008 (2008) Petroleum and chemical industry association of China, rubber, vulcanized or thermoplastic-determination of tear strength (trouser, angle and crescent test pieces). Chinese Code Press, Beijing (in Chinese)

GB/T 531.1-2008 (2008) Petroleum and chemical industry association of China, rubber, vulcanized or thermoplastic-determination of indentation hardness-Part1: duromerer method (shore hardness). Chinese Code Press, Beijing (in Chinese)

GB/T 7759.1-2015 (2015) Petroleum and chemical industry association of China, rubber, vulcanized or thermoplastic-determination of compression set-Part 1: at ambient or elevated temperatures. Chinese Code Press, Beijing (in Chinese)

Zhu LQ, Huang HJ, Yang F, Zhang B (2006) Study on aging failure of natural rubber vulcanizate in neutral salt spray environment. National Aerospace Equipment Failure Analysis Seminar

He SX, Luo QK (2005) Study on tensile fracture behavior of IIR/EPDM blend vulcanizate. Spec Purp Rubber 26(3):1–5

Qiu YW (2015) Preparation, structure and properties of styrene-butadiene rubber filled with carbon black. Dissertation, South China University of Technology

Ding L, Li ZH, Yang H, Wang XP, Liang LH, Zhong JY, Zhou YS (2018) Aging mechanism of natural rubber. Polym Mater Sci Eng 5:76–83

Xie FW, Zhang TL, Bryant P, Kurusingal V, Colwell JM, Laycock B (2019) Degradation and stabilization of polyurethane elastomers. Prog Polym, Sci

Seentrakoon B, Junhasavasdikul B, Chavasiri W (2013) Enhanced UV protection and antibacterial properties of natural rubber rutileTiO2 nanocomposites. Polym Degrad Stab 98(2):566–578

Liu CP, Wu HJ, Ye CH, Chen MF, Zhong W, Wu JH (2011) Effect of accelerator on anti-aging and yellowing resistance of light-colored vulcanized rubber. Polym Mater Sci Eng 27(11):97–100

Adam C, Lacoste J, Lemaire J (1991) Photo-oxidation of polyisoprene. Polym Degrad Stab 32(1):51–69

Acknowledgements

The authors wish to thank the help of Dr M.Z. Guo in manuscript preparation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, S.M., Yu, L., Gao, J.X. et al. Durability of rubber waterstop in extreme environment: effect and mechanisms of ultraviolet aging. Polym. Bull. 78, 4019–4032 (2021). https://doi.org/10.1007/s00289-020-03275-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03275-4