Abstract

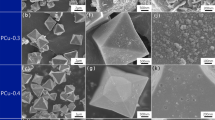

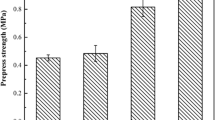

As a way of reducing the formaldehyde emission and improving the adhesion of urea–formaldehyde (UF) resins, this study investigated the addition effects of pristine nanoclay (PNC) or modified nanoclay (MNC) with transition metal ion (TMI) on the performance of UF resin adhesives. Instead of a conventional simple mixing (SM) of MNC with UF resin (coded as MNC-SM), this study explored adding PNC or MNC into either the alkaline (ALK) or acidic (ACD) reaction during the synthesis of UF resins, which were coded as PNC-ALK, PNC-ACD, MNC-ALK, and MNC-ACD, respectively. For the first time, we report that the MNC-ALK resins result in almost amorphous UF resins with 25% crystallinity, which consequently increases the cross-linking, and improve the adhesion strength and decrease formaldehyde emission of modified UF resins. It is believed that the intercalated or exfoliated MNCs facilitate the formation of more cross-linking in the modified UF resins, leading to a better cohesive strength.

Similar content being viewed by others

References

Pizzi A, Mittal KL (2017) Handbook of adhesive technology. CRC Press, Boca Raton

Lubis MAR, Park BD (2018) Modification of urea-formaldehyde resin adhesives with oxidized starch using blocked pMDI for plywood. J Adhes Sci Technol 32(24):2667–2681

Jeong B, Park BD (2019) Effect of molecular weight of urea-formaldehyde resins on their cure kinetics, interphase, penetration into wood, and adhesion in bonding wood. Wood Sci Technol 53(3):665–685

Gao S, Liu Y, Wang C, Chu F, Xu F, Zhang D (2020) Synthesis of lignin-based polyacid catalyst and its utilization to improve water resistance of urea-formaldehyde resins. Polymers 12(1):175

Que Z, Furuno T, Katoh S, Nishino Y (2007) Evaluation of three test methods in determination of formaldehyde emission from particleboard bonded with different mole ratio in the urea-formaldehyde resin. Build Environ 42(3):1242–1249

Stuligross J, Koutsky JA (1985) A morphological study of urea-formaldehyde resins. J Adhes 18(4):281–299

Levendis D, Pizzi A, Ferg E (1992) The correlation of strength and formaldehyde emission with the crystalline/amorphous structure of UF resins. Holzforschung-Int J Biol Chem Phys Technol Wood 46(3):263–269

Pratt TJ, Johns WE, Rammon RM, Plagemann WL (1985) A novel concept on the structure of cured urea-formaldehyde resin. J Adhes 17(4):275–295

Despres A, Pizzi A (2006) Colloidal aggregation of aminoplastic polycondensation resins: urea-formaldehyde versus melamine-formaldehyde and melamine-urea-formaldehyde resins. J Appl Polym Sci 100(2):1406–1412

Park BD, Jeong HW, Lee SM (2011) Morphology and chemical elements detection of cured urea-formaldehyde resins. J Appl Polym Sci 120(3):1475–1482

Park BD, Causin V (2013) Crystallinity and domain size of cured urea-formaldehyde resin adhesives with different formaldehyde/urea mole ratios. Eur Polym J 49(2):532–537

Pizzi A (1990) A molecular mechanics approach to the adhesion of urea-formaldehyde resins to cellulose. Part 2. Amorphous versus crystalline cellulose I. J Adhes Sci Technol 4(1):589–595

Ferg EE, Pizzi A, Levendis DC (1993) 13C NMR analysis method for urea-formaldehyde resin strength and formaldehyde emission. J Appl Polym Sci 50(5):907–915

Cho J, Joshi MS, Sun CT (2006) Effect of inclusion size on mechanical properties of polymeric composites with micro and nano particles. Compos Sci Technol 66(13):1941–1952

Jacobs O, Xu W, Schädel B, Wu W (2006) Wear behaviour of carbon nanotube reinforced epoxy resin composites. Tribol Lett 23(1):65–75

Lei H, Du G, Pizzi A, Celzard A (2008) Influence of nanoclay on urea-formaldehyde resins for wood adhesives and its model. J Appl Polym Sci 109(4):2442–2451

Nawani P, Gelfer MY, Hsiao BS, Frenkel A, Gilman JW, Khalid S (2007) Surface modification of nanoclays by catalytically active transition metal ions. Langmuir 23(19):9808–9815

Singh AP, Causin V, Nuryawan A, Park BD (2014) Morphological, chemical and crystalline features of urea-formaldehyde resin cured in contact with wood. Eur Polym J 56:185–193

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29(11):1702–1706

Esposito A, Delpouve N, Causin V, Dhotel A, Delbreilh L, Dargent E (2016) From a three-phase model to a continuous description of molecular mobility in semicrystalline poly (hydroxybutyrate-co-hydroxyvalerate). Macromolecules 49(13):4850–4861

Nakas GI, Kaynak C (2009) Use of different alkylammonium salts in clay surface modification for epoxy-based nanocomposites. Polym Compos 30(3):357–363

Otsuka E, Kudo S, Sugiyama M, Suzuki A (2011) Effects of microcrystallites on swelling behavior in chemically crosslinked poly (vinyl alcohol) gels. J Polym Sci Part B Polym Phys 49(2):96–102

Park BD, Kim JW (2008) Dynamic mechanical analysis of urea-formaldehyde resin adhesives with different formaldehyde-to-urea molar ratios. J Appl Polym Sci 108(3):2045–2051

Yeh SK, Kim KJ, Gupta RK (2013) Synergistic effect of coupling agents on polypropylene-based wood–plastic composites. J Appl Polym Sci 127(2):1047–1053

Salari A, Tabarsa T, Khazaeian A, Saraeian A (2012) Effect of nanoclay on some applied properties of oriented strand board (OSB) made from underutilized low quality paulownia (Paulownia fortunei) wood. J Wood Sci 58(6):513–524

Salari A, Tabarsa T, Khazaeian A, Saraeian A (2013) Improving some of applied properties of oriented strand board (OSB) made from underutilized low quality paulownia (Paulownia fortunie) wood employing nano-SiO2. Ind Crops Prod 42:1–9

Zeng QH, Yu AB, Lu GQ, Paul DR (2005) Clay-based polymer nanocomposites: research and commercial development. J Nanosci Nanotechnol 5(10):1574–1592

Lin Q, Yang G, Liu J, Rao J (2006) Property of nano-SiO 2/urea formaldehyde resin. Front For China 1(2):230

Acknowledgements

This work was supported by the National Research Foundation (NRF) of Korea funded by the Korean government (MSIT) (Grant#: 2020R1A2C1005042).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yadav, S.M., Lubis, M.A.R., Wibowo, E.S. et al. Effects of nanoclay modification with transition metal ion on the performance of urea–formaldehyde resin adhesives. Polym. Bull. 78, 2375–2388 (2021). https://doi.org/10.1007/s00289-020-03214-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03214-3