Abstract

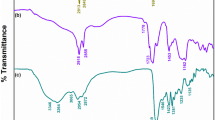

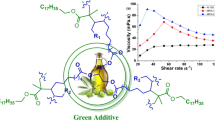

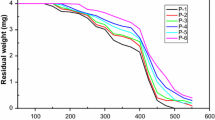

Three novel multifunctional additives (MFAs), poly(alkyl acrylate-co-maleic anhydride)-based amide copolymers, were synthesized by the reaction between intermediate alkyl acrylate-co-maleic anhydride and three different amines, viz. octylamine (MFA 1), dodecylamine (MFA 2), and octadecylamine (MFA 3). Additives were successfully prepared by the polymerization route using benzoyl peroxide (Bz2O2) as a free radical initiator. Analytical techniques such as Fourier transform infrared, nuclear magnetic resonance, and gel permeation chromatography were used to characterize the synthesized polymeric compounds. Polyol was taken as reference base oil for performance evaluation of the synthesized polymers as multifunctional additive for viscosity index improver, pour point depressant, anti-wear, anti-friction, detergent–dispersant, and anti-corrosion properties. MFA 1 reflected the best performance as detergent–dispersant and anti-corrosive additive with observed increment of ~ 48% and ~ 54%, respectively, in comparison with blank polyol. MFA 3 showed the best viscosity index improving property which enhanced the viscosity index of polyol base oil from 191.85 to 250.45 at 3000 ppm. It also showed best tribological performance in 3000 ppm concentration at which the average wear scar diameter and average friction coefficient values decrease to 482 µm and 0.0823 from the 690 µm and 0.1276 for blank polyol.

Similar content being viewed by others

References

Roy M, Mortier RM, Fox MF, Orszulik ST (2010) Chemistry and technology of lubricants, 3rd edn. Springer, Heidelberg

Leslie RR (2009) Lubricant additives: chemistry and applications. Taylor & Francis Group, Boca Raton

Ludema KC (1996) Friction, wear, lubrication: a textbook in tribology. CRC Press L.L.C., Boca Raton, pp 124–134

Rizvi SQA (2009) A comprehensive review of lubricant chemistry, technology, selection, and design. ASTM International, West Conshohocken, pp 100–112

Ghosh P, Das M (2014) Study of the influence of some polymeric additives as viscosity index improvers and pour point depressant—synthesis and characterization. J Pet Sci Eng 119:79–84

Mohamed SA, Ahmed NS, Hassanein SM, Rashad AM (2012) Investigation of polyacrylates copolymers as lube oil viscosity index improvers. J Petrol Sci Eng 100:173–177

Singh AK, Singh RK (2012) A search for eco-friendly detergent/dispersant additives for vegetable-oil based lubricants. J. Surfactants Deterg 15(4):399–409

Ghosh P, Karmakar G (2012) Synthesis and characterization of polymyristyl acrylate as a potential additive for lubricating oil. Am J Polym Sci 2(1):1–6

Ghosh P, Das T, Karmakar G, Das M (2011) Evaluation of acrylate—sunflower oil copolymer as viscosity index improvers for lube oil. J Chem Pharm Res 3(3):547–556

Karmakar G, Ghosh P (2016) Atom transfer radical polymerization of soybean oil and its evaluation as a biodegradable multifunctional additive in the formulation of eco-friendly lubricant. ACS Sustain Chem Eng 4:775–781

Upadhyay M, Karmakar G, Kapur GS, Ghosh P (2017) Multifunctional greener additives for lubricating oil. Polym Eng Sci 58(5):810–815

Yumin W, Guangdi N, Fei Y, Chuanxian L, Guoliang D (2012) Modified maleic anhydride copolymers as pour-point depressants and their effects on waxy crude oil rheology. Energy Fuels 26:995–1001

Abdel-Azim AAA, Nasser AM, Ahmed NS, Kafrawy AFEI, Kamal RS (2009) Multifunctional additives viscosity index improvers, pour point depressants and dispersants for lube oil. Petrol Sci Techol 27:20–32

Ghosh P, Hoque M, Karmakar G, Yeasmin S (2017) Castor oil-based multifunctional greener additives for lubricating oil. Curr Environ Eng 4(3):197–206

Ghosh P, Talukder S, Upadhyay M, Das T (2016) Multifunctional additive performance of acrylate-styrene copolymers. J Sci Ind Res 75:420–426

Singh RK, Kukrety A, Kumar A, Chouhan A, Saxena RC, Ray SS, Jain SL (2018) Synthesis, characterization and performance evaluation of N, N-Dimethylacrylamide–alkyl acrylate co-polymers as novel multi-functional additives for lube oil. Adv Polym Technol 37(6):1695–1702

Ghosh P, Das M, Upadhyay M, Das T, Mandal A (2011) Synthesis and evaluation of acrylate polymers in lubricating oil. J Chem Eng Data 56:3752–3758

Brandi G, Koch P, Maiorana S, Croce PD, Baldoli C (1986) Multifunctional additive for lubricating oils and process for the preparation thereof. US Patent No. US4618439A

Khalkar S, Bhowmick DN, Pratap A (2013) Synthesis of polymers from fatty alcohol and acrylic acid and its impact on tribological properties. J Oleo Sci 62(3):167–173

ASTM D2270-10 (2016) Standard practice for calculating viscosity index from kinematic viscosity at 40 °C and 100 °C. In: Annual Book of ASTM Standards. ASTM International, West Conshohocken, PA

ASTM D97-17b (2017) Standard test method for pour point of petroleum products. In: Annual Book of ASTM Standards. ASTM International, West Conshohocken, PA

ASTM D4172 (2010) Standard test method for wear preventive characteristics of lubricating fluid (Four-Ball Method). In: Annual Book of ASTM Standards. ASTM International, West Conshohocken, PA

ASTM D7899-13 (2013) Standard test method for measuring the merit of dispersancy of in-service engine oils with blotter spot method. In Annual Book of ASTM Standards. ASTM International, West Conshohocken, PA

Champion FA (ed) (1964) Corrosion testing procedure. Champion & Hall, London, p 66

Ailor WH (ed) (1971) Handbook of corrosion testing and evaluation. Wiley, New York, p 119

ASTM D664-11a (2011) Standard test method for acid number products by potentiometric titration. In: Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA

Singh RK, Kukrety A, Thakre GD, Atray N, Ray SS (2015) Development of new eco-friendly detergent/dispersant/antioxidant/antiwear additives from l-histidine for bio lubricant applications. RSC Adv 5(47):37649–37656

ASTM International (2019) D3228-08(2019) standard test method for total nitrogen in lubricating oils and fuel oils by modified Kjeldahl method. West Conshohocken, PA

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Faujdar, E., Negi, H., Kukrety, A. et al. Study of alkyl acrylate-co-maleic anhydride-based novel amide copolymers as multifunctional lubricant additives. Polym. Bull. 78, 2085–2102 (2021). https://doi.org/10.1007/s00289-020-03204-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03204-5