Abstract

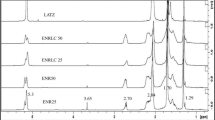

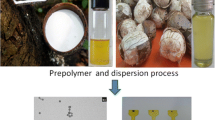

Vegetable oil with the advantages of biodegradability and low cost has been used as a plasticizer in the rubber industry. This study investigates the conditions of vegetable oil nanoemulsion as a plasticizer in natural rubber (NR) latex. Vegetable oil nanoemulsion with the particle size of 10.4 nm is prepared from blending coconut kernel oil/soybean oil, Tween 80 and water using phase inversion temperature method. The vegetable oil nanoemulsion is then added to NR latex. During the initial three days, latex particles have swollen, but subsequently they shrunk from 2673 to 1511 nm due to phase inversion. The result indicates that the tensile strength of latex films could be improved significantly with both higher incubation and vulcanization temperatures at 50 °C and 120 °C, respectively. Contact angle on the film surface is less than 90°, showing that there is no oil blooming onto the surface.

Similar content being viewed by others

References

Parker SP (ed) (2003) McGraw-Hill dictionary of scientific and technical terms. McGraw-Hill Education, New York

Whelan A (2012) Polymer technology dictionary. Springer, Berlin

Chin PS, O’Connell J (1969) Oil extension of natural rubber at latex stage. J Rubb Res Inst Malaya 22:91–103

Kondo H (2016) Oil-extended natural rubber and method for producing the same and rubber composition and tire using the same. US Patent 9,487,047B2, 8 Nov 2016

Sakaki T, Ichikawa N, Hattori T, Ho CC, Choong DH (2011) Preparation process of oil extended rubber for tire, oil extended rubber for tire, and rubber composition and tire using the same. US Patent 8,044,118B2, 25 Oct 2011

Wendling P, Peter R, Koski AA (2001) Process for preparation of rubber silica masterbatches based on the use of polymer lattices. CA 2381514A1, 15 Feb 2001

Song GJ et al (2009) Preparation of oil-extended montmorillonite-extended latex coprecipitation rubber. CN Patent 101475714A, 8 Jul 2009

Ichikawa N, Nobuchika H (2005) Compounded deproteinized natural rubber latex and dipped rubber product using the same. JP Patent 2005120153A, 12 May 2005

Nandanan V (2000) Studies on the use of drying oils as ingredients in the vulcanization of elastomer. Dissertation, Cochin University of Science and Technology

Ciesielski A (2001) An introduction to rubber technology. iSmithers Rapra Publishing, Shrewsbury

Jayewardhana WGD, Perera GM, Edirisinghe DG, Karunanayake L (2009) Study on natural oils as alternative processing aids and activators in carbon black filled natural rubber. J Natl Sci Found Sri Lanka 37:187–193

Li J, Isayev AI, Ren X, Soucek MD (2015) Modified soybean oil-extended SBR compounds and vulcanizates filled with carbon black. Polymer 60:144–156

Heng YX, Lee SY, Cheong KW, Heng YK, Ling YTQ, Tan ST (2018) Effect of emulsion particle size on the natural rubber latex film properties in the presence of renewable lipid emulsions. In: Dzaraini K et al. (eds) National symposium on polymeric materials 2017, Selangor, October 2017. AIP conference proceedings, vol 1985. AIP Publishing, Melville, p 040002

Ling YTQ, Lee SY, Cheong KW, Tay SL, Tan ST, Heng YX (2018) Swelling of natural rubber latexes in vegetable oil emulsion: particle size measurement. In: Dzaraini K et al. (eds) National symposium on polymeric materials 2017, Selangor, October 2017. AIP Conference Proceedings, vol 1985. AIP Publishing, Melville, p 040003

Lee SY, Fauzi MS, Amir HMY, Heng YX, Ling YTQ (2018) A novel vegetable oil nanoemulsion-plasticized natural rubber latex compound: effect of ingredient blending sequence on crosslink density and tensile strengths. In: Dzaraini K et al. (eds) National symposium on polymeric materials 2017, Selangor, October 2017. AIP conference proceedings, vol 1985. AIP Publishing, Melville, p 040013

Lee SY, Ng A, Singh MSJ, Liew YK, Gan SN, Koh RY (2017) Physicochemical and antimicrobial properties of natural rubber latex films in the presence of vegetable oil microemulsions. J Appl Polym Sci 134:44788

Lee SY, Tan ST, Cheong KW, Kuok KM, Heng YX, Ling YTQ (2018) Development of biocompatible natural rubber latex film incorporated with vegetable oil microemulsion as plasticizer: Effect of curing conditions. In: Dzaraini K et al. (eds) National symposium on polymeric materials 2017, Selangor, October 2017. AIP conference proceedings, vol 1985. AIP Publishing, Melville, p 040004

Chaikumpollert O, Yamamoto Y, Suchiva K, Kawahara K (2012) Mechanical properties and cross-linking structure of cross-linked natural rubber. Polym J 44:772–777

Valentin JL, Carretero-Gonzalez J, Mora-Barrantes I, Chasse W, Saalwachter K (2008) Uncertainties in determination of cross-link density by equilibrium swelling experiments in natural rubber. Macromolecules 41:4717–4729

Orwoll RA (2007) Densities, coefficients of thermal expansion, and compressibilities of amorphous polymers. In: Mark JE (ed) Physical properties of polymer handbook, vol 2. Springer, New York, pp 93–102

Tanford C (1973) The hydrophobic effect: formation of micelles and biology. Wiley, New York

Israelachivili JN, Mitchell DJ, Ninham BW (1976) Theory of self-assembly of hydrocarbon amphiphiles into micelles and bilayers. J Chem Soc, Faraday Trans 2(72):1525–1568

Nagarajan R, Ruckenstein E (1991) Theory of surfactant self-assembly: a predictive molecular thermodynamic approach. Langmuir 7:2934–2969

Nagarajan R (2003) Theory of micelle formation: Quantitative approach to predicting the micellar properties from surfactant molecular structure. In: Esumi K, Ueno M (eds) Structure-performance relationships in surfactants. Marcel Dekker, New York, pp 1–89

Nagarajan R, Ruckenstein E (2000) Self-assembled systems. In: Sengers JV, Kayser RF, Peters CJ, White HJ (eds) Equations of state for fluids and fluid mixtures, vol 5. Elsevier Science, Amsterdam, pp 589–749

Nagarajan R (2002) Molecular packing parameter and surfactant self-assembly: neglected role of the surfactant tail. Langmuir 18:31–38

Yu L, Li C, Xu J, Hao J, Sun D (2012) Highly stable concentrated nanoemulsions by the phase inversion composition method at elevated temperature. Langmuir 28:14547–14552

Silverajah VS, Ibrahim NA, Yunus WMZW, Hassan HA, Chieng BW (2012) A comparative study on the mechanical, thermal and morphological characterization of poly(lactic acid)/epoxidized palm oil blend. Int J Mol Sci 13:5878–5898

Norhazariah S, Azura AR, Sivakumar R, Azahari B (2016) Effect of different preparation methods on crosslink density and mechanical properties of carrageenan filled natural rubber (NR) latex films. Procedia Chem 19:986–992

Ho CC, Khew MC (2000) Surface free energy analysis of natural and modified natural rubber latex films by contact angle method. Langmuir 16:1407–1414

Acknowledgements

The authors would like to extend heartfelt appreciation and gratitude to Dr. Manroshan Singh Jaswan Singh from Malaysian Rubber Board for providing technical advice.

Funding

This work was supported by Malaysian Rubber Board (Grant number: S17STL0663).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Heng, Y.X., Ling, Y.T.Q., Lee, S.Y. et al. Natural rubber latex film in the presence of renewable vegetable oil nanoemulsion. Polym. Bull. 78, 2103–2120 (2021). https://doi.org/10.1007/s00289-020-03201-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03201-8