Abstract

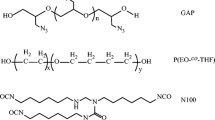

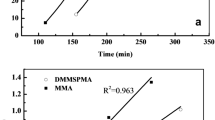

In this paper, ethylene–vinyl acetate–glycidyl methacrylate terpolymer elastomer (EVM–GMA) was vulcanized by methyltetrahydrophthalic anhydride (MTHPA) and cross-linked by dicumyl peroxide (DCP) as a reference. Mechanical properties and hot-air aging properties were investigated. The cross-linking mechanism of EVM–GMA reacting with MTHPA was proposed, and a “model vulcanization reaction’ was designed to prove its rationality. The reaction products were characterized by GPC, FT-IR, GC–MS, 1H-NMR and so on. The results indicated that the cured torque MH − ML and cross-link density of EVM–GMA increased first and then decreased with the increase in amount of MTHPA. An optimum of curing, mechanical properties and aging resistance were found at a molar ratio of anhydride to GMA of 1:2. The MTHPA curing reaction catalyzed by tetrabutylammonium bromide was faster compared to the selected DCP cure system, and the mechanical properties, compression set and hot-air aging performance were superior as well. The “model vulcanization reaction” indicated that one molecule of MTHPA successfully reacted with two molecules of the mono-epoxy compound of glycidyl–versatic ester (E10P) to form a hydroxyl-terminated epoxy–anhydride–epoxy polyester structure. Therefore, one molecule of MTHPA can “bridge” two epoxy side groups (provided by GMA) on the adjacent molecular chain of EVM–GMA to realize rubber cross-linking, which proved that the cross-linking mechanism based on epoxy–anhydride reaction for EVM–GMA elastomer proposed in this paper was reasonable.

Similar content being viewed by others

References

Cárdenas MÁ, Basurto FC, García-López D (2013) Mechanical and fire retardant properties of EVA/clay/ATH nanocomposites: effect of functionalization of organoclay nanofillers. Polym Bull 70(8):2169–2179. https://doi.org/10.1007/s00289-013-0925-0

Bahattab MA, Mosnáček J, Basfar AA (2010) Cross-linked poly(ethylene vinyl acetate) (EVA)/low density polyethylene (LDPE)/metal hydroxides composites for wire and cable applications. Polym Bull 64(6):569–580. https://doi.org/10.1007/s00289-009-0194-0

Wang CL, Kobayashi Y, Zheng W (2001) Positronium formation in PE/EVA polymer blends at low temperatures. Polymer 42(6):2359–2364. https://doi.org/10.1016/s0032-3861(00)00609-1

Zanetti M, Costa L (2004) Preparation and combustion behaviour of polymer/layered silicate nanocomposites based upon PE and EVA. Polymer 45(13):4367–4373. https://doi.org/10.1016/j.polymer.2004.04.043

Zhang ZX, Wang WY, Yang JH (2016) Excellent electroactive shape memory performance of EVA/PCL/CNT blend composites with selectively localized CNTs. J Phys Chem C 120(40):22793–22802. https://doi.org/10.1021/acs.jpcc.6b06345

Lacroix C, Bousmina M, Carreau PJ (1996) Properties of PETG/EVA blend: 1. Viscoelastic, morphological and interfacial properties. Polymer 37(14):2939–2947. https://doi.org/10.1016/0032-3861(96)89389-x

Bahloul W, Bounor-Legaré V, Fenouillot F (2009) EVA/PBT nanostructured blends synthesized by in situ polymerization of cyclic cBT (cyclic butylene terephthalate) in molten EVA. Polymer 50(12):2527–2534. https://doi.org/10.1016/j.polymer.2009.03.055

Tang Z, Huang J, Guo B (2016) Bioinspired engineering of sacrificial metal-ligand bonds into elastomers with supramechanical performance and adaptive recovery. Macromolecules 49(5):1781–1789. https://doi.org/10.1021/acs.macromol.5b02756

Huang J, Tang Z, Yang Z (2016) Bioinspired interface engineering in elastomer/graphene composites by constructing sacrificial metal-ligand bonds. Macromol Rapid Commun 37(13):1040–1045. https://doi.org/10.1002/marc.201600226

Xu C, Huang X, Li C (2016) Design of “Zn2+ salt-bondings” crosslinked carboxylated styrene butadiene rubber with reprocessing and recycling ability via rearrangements of ionic crosslinkings. Acs Sustain Chem Eng 4(12):6981–6990. https://doi.org/10.1021/acssuschemeng.6b01897

Xu C, Cao L, Lin B (2016) Design of self-healing supramolecular rubbers by introducing ionic cross-links into natural rubber via a controlled vulcanization. ACS Appl Mater Interfaces 8(27):17728–17737. https://doi.org/10.1021/acsami.6b05941

Xu P, Zhao X, Ma P (2018) Design of nano-starch-reinforced ethyl-co-vinyl acetate elastomers by simultaneously constructing interfacial bonding and novel reversible matrix crosslinking. Chem Eng J 346(18):497–505. https://doi.org/10.1016/j.cej.2018.03.189

Rocks J, Rintoul L, Vohwinkel F (2004) The kinetics and mechanism of cure of an amino-glycidyl epoxy resin by a co-anhydride as studied by FT-Raman spectroscopy. Polymer 45(20):6799–6811. https://doi.org/10.1016/j.polymer.2004.07.066

Xiong X, Lu Z, Rong R (2018) Thermal, mechanical properties and shape memory performance of a novel phthalide-containing epoxy resins. Polymer 140(18):326–333. https://doi.org/10.1016/j.polymer.2018.02.043

Mijović J, Tsay L (2015) Correlations between dynamic mechanical properties and nodular morphology of cured epoxy resins. Polymer 22(7):902–906. https://doi.org/10.1016/0032-3861(81)90265-2

Galpaya DGD, Fernando JFS, Rintoul L (2015) The effect of graphene oxide and its oxidized debris on the cure chemistry and interphase structure of epoxy nanocomposites. Polymer 71:122–134. https://doi.org/10.1016/j.polymer.2015.06.054

Amirova LR, Burilov AR, Amirova LM (2016) Kinetics and mechanistic investigation of epoxy-anhydride compositions cured with quaternary phosphonium salts as accelerators. J Polym Sci Polym Chem 54(8):1088–1097. https://doi.org/10.1002/pola.27946

Hu LF, Zhang CJ, Wu HL (2018) Highly active organic lewis pairs for the copolymerization of epoxides with cyclic anhydrides: metal-free access to well-defined aliphatic polyesters. Macromolecules 51(8):3126–3134. https://doi.org/10.1021/acs.macromol.8b00499

Gang S, Sun H, Liu YU (2007) Comparative study on the curing kinetics and mechanism of a lignin-based-epoxy/anhydride resin system. Polymer 48(1):330–337. https://doi.org/10.1016/j.polymer.2006.10.047

Yu Y, Zhong X, Su H (2010) Simultaneous cationic polymerization and esterification of epoxy/anhydride system in the presence of polyoxometalate catalyst. Polymer 51(7):1563–1571. https://doi.org/10.1016/j.polymer.2010.02.007

Rohde BJ, Robertson ML, Krishnamoorti R (2015) Concurrent curing kinetics of an anhydride-cured epoxy resin and polydicyclopentadiene. Polymer 69:204–214. https://doi.org/10.1016/j.polymer.2015.04.066

ÖzdenYenigün E, Menceloğlu YZ, Papila M (2012) MWCNTs/P(St-co-GMA) composite nanofibers of engineered interface chemistry for epoxy matrix nanocomposites. ACS Appl Mater Interfaces 4(2):777–784. https://doi.org/10.1021/am2014162

Xu P, Ma P, Cai X (2016) Selectively cross-linked poly (lactide)/ethylene-glycidyl methacrylate-vinyl acetate thermoplastic elastomers with partial dual-continuous network-like structures and shape memory performances. Eur Polym J 84(1):1–12. https://doi.org/10.1016/j.eurpolymj.2016.09.004

Sha GB (2016) Aspects of varying crosslinker and catalyst concentrations on tear strength of silicone polymer networks: comparison of tear strengths using samples of different geometries. J Appl Polym Sci 133(15):43115. https://doi.org/10.1002/app.43115

Colonna S, Cuttica F, Frache A (2014) Aging of EVA/organically modified clay: effect on dispersion, distribution and combustion behavior. Polym Degrad Stab 107(14):184–187. https://doi.org/10.1016/j.polymdegradstab.2014.05.019

Han SW, Choi NS, Ryu SR (2017) Mechanical property behavior and aging mechanism of carbon-black-filled EPDM rubber reinforced by carbon nano-tubes subjected to electro-chemical and thermal degradation. J Mech Sci Technol 31(9):4073–4078. https://doi.org/10.1007/s12206-017-0802-0

Chen S, Zhang J (2010) Effect of hot air aging on the properties of ethylene-vinyl acetate copolymer and ethylene-acrylic acid copolymer blends. J Appl Polym Sci 114(5):3110–3117. https://doi.org/10.1002/app.30859

Shi X, Zhang P, Liang Y (2007) Preparation and compatibility of EVM/TPU blend. J Macromol Sci B 46(4):807–824. https://doi.org/10.1080/00222340701389258

Li MS, Su YF, Ma CCM (1996) Transesterification and cyclization of polycarbonate-epoxy blends cured with anhydride. Polymer 37(17):3899–3905. https://doi.org/10.1016/0032-3861(96)00215-7

Jentsch A, Eichhorn KJ, Voit B (2015) Influence of typical stabilizers on the aging behavior of EVA foils for photovoltaic applications during artificial UV-weathering. Polym Test 44(3):242–247. https://doi.org/10.1016/j.polymertesting.2015.03.022

Yu H, Yong Z, Chen S (2010) Study on the properties of ethylene-vinyl acetate rubber vulcanizate filled with superfluous magnesium hydroxide/methacrylic acid. J Appl Polym Sci 119(3):1813–1819. https://doi.org/10.1002/app.32876

Sharma BK, Krishnanand K, Mahanwar PA (2018) Gamma radiation aging of EVA/EPDM blends: effect of vinyl acetate (VA) content and radiation dose on the alteration in mechanical, thermal, and morphological behavior. J Appl Polym Sci 135(18):46216. https://doi.org/10.1002/app.46216

White JS (1983) Curing epoxy resins with anhydrides: model reactions and reaction mechanism. J Polym Sci Polym Chem 21(10):2873–2885. https://doi.org/10.1002/pol.1983.170211003

Penn LS, Chiao TT (1982) Epoxy resins. In: Lubin G (ed) Handbook of composites. Springer, Berlin, pp 57–88. https://doi.org/10.1007/978-1-4615-7139-1_5

Ollier-Dureault V, Gosse B (1998) Photooxidation of anhydride-cured epoxies: FTIR study of the modifications of the chemical structure. J Appl Polym Sci 70(6):1221–1237. https://doi.org/10.1002/(sici)1097-4628(19981107)70:6%3c1221:aid-app19%3e3.0.co;2-1

Huang ZY, Lu SR, Yang ZY (2011) Studies on the properties of epoxy resins modified with novel liquid crystalline polyurethane. Adv Mater Res 150–151(9):727–731. https://doi.org/10.4028/www.scientific.net/AMR.150-151.727

Huang K, Liu Z, Zhang J (2014) Epoxy monomers derived from tung oil fatty acids and its regulable thermosets cured in two synergistic ways. Biomacromol 15(3):837–843. https://doi.org/10.1021/bm4018929

Acknowledgements

The authors would like to acknowledge the support of Natural Science Foundation of Shandong Province (ZR2018MEM025) and Arlanxeo, without which the work presented in this article, would not have been possible.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ji, X., Zhang, M., Yin, H. et al. Properties and mechanism of EVM–GMA terpolymer elastomer cross-linked by epoxy–anhydride reaction. Polym. Bull. 78, 769–794 (2021). https://doi.org/10.1007/s00289-020-03133-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03133-3