Abstract

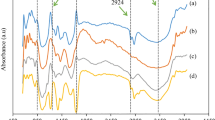

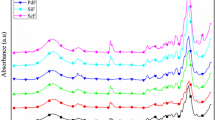

Modification of cellulose fibers is a promissory alternative for the production of new composite materials, but the high hydrophilicity of cellulose limits its use as a reinforcing agent in the making of olefin-based composites. The aim of this research was to develop reinforcing agents based on cellulose fibers modified by insertion of end-alkyl groups from pyrolytic bio-oil (PBO). For that, PBO of sugarcane bagasse was obtained and characterized by several techniques including gas chromatography coupled to mass spectrometry. Later, the surface of cellulose fibers was activated using methylene-bis-isocyanate and modified using acetic acid, formic acid, and PBO. Results show that the modification of cellulose surface is possible by the use of PBO at low temperature obtaining results like to those obtained when organic acids are used.

Similar content being viewed by others

References

Kumar V, Kumari M (2014) Processing and characterization of natural cellulose fibers/thermoset polymer composites. Carbon Polym 109:102–117. https://doi.org/10.1016/j.carbpol.2014.03.039

Ng HM, Sin LT, Bee ST, Tee TT, Tahmat AR (2017) Review of nanocellulose polymer composite characteristics and challenges. Polymer-Plastic Technol Eng 56:687–731. https://doi.org/10.1080/03602559.2016.1233277

Pappu A, Pickering K, Kumar V (2019) Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as reinforcement of poly(lactic acid) via injection moulding. Ind Crops Prod 137:260–269. https://doi.org/10.1016/j.indcrop.2019.05.040

Moshiul AK, Beg MD, Reddy DM, Khan MR, Mina MF (2012) Structures and performances of simultaneous ultrasound and alkali treated oil palm empty fruit bunch fiber reinforced poly(lactic acid) composites. Compos Part A Appl Sci Manuf 43:1921–1929. https://doi.org/10.1016/j.compositesa.2012.06.012

Belgacem RN, Gandini A (2005) The surface modification of cellulose fibres for use as reinforcing elements in composite materials. Compos interf 12:41–75. https://doi.org/10.1163/1568554053542188

Alila S, Boufi S (2009) Removal of organic pollutants from water by modified cellulose fibres. Ind Crops Prod 30:93–104. https://doi.org/10.1016/j.indcrop.2009.02.005

Alila S, Ferraria AM, Botelho do Rego AM, Boufi S (2009) Controlled surface modification of cellulose fibers by amino derivatives using N,N′-carbonyldiimidazole as activator. Carbohydr Polym 77:553–562. https://doi.org/10.1016/j.carbpol.2009.01.028

Elegir G, Kindl A, Sadocco P, Orlandi M (2008) Development of antimicrobial cellulose packaging through laccase-mediated grafting of phenolic compounds. Enzyme Microbial Technol 43:84–92. https://doi.org/10.1016/j.enzmictec.2007.10.003

Palencia M, Berrio ME, García-Quintero A, Lerma T (2019) In: Giri T, Ghosh B (eds) Polysacharide-based nano-biocarrier in drug delivery. CRC Press, Boca Raton, Chapter 3, pp 39–62

Jedvert K, Heinze T (2017) Cellulose modification and shaping—a review. J Polym Eng 37:845–860. https://doi.org/10.1515/polyeng-2016-0272

Hajlane A, Kaddami H, Joffe R (2017) Chemical modification of regenerated cellulose fibers by cellulose nano-crystals: towards hierarchical structure for structural composites reinforcement. Ind Crops Prod 100:41–50. https://doi.org/10.1016/j.indcrop.2017.02.006

Sultan M, Mahmood K, Nawaz H, Jamil T, Hussain R, Zuber M (2012) Modification of cellulosic fiber with polyurethane acrylate copolymers. Part I Physicochemical properties. Carbohyd Polym 87:397–404. https://doi.org/10.1016/j.carbpol.2011.07.070

Gustavsson MT, Persson PV, Iversen T, Martinelle M, Hult K, Teeri TT, Brumer H (2005) Modification of cellulose fiber surfaces by use of a lipase and a xyloglucan endotransglycosylase. Biomacromol 6:196–203. https://doi.org/10.1021/bm049588i

Ramesh S, Shanti R, Morris E (2013) Characterization of conducting cellulose acetate based polymer electrolytes doped with “green” ionic mixture. Carbohyd Polym 91:14–21. https://doi.org/10.1016/j.carbpol.2012.07.061

Meier D, Faix O (1999) State of the art of applied fast pyrolysis of lignocellulosic materials—a review. Biores Technol 68:71–77. https://doi.org/10.1016/S0960-8524(98)00086-8

Stefanidis SD, Kalogiannis KG, Iliopoulou EF et al (2014) A study of lignocellulosic biomass pyrolysis via the pyrolysis of cellulose, hemicellulose and lignin. J Anal Appl Pyrol 105:143–150. https://doi.org/10.1016/j.jaap.2013.10.013

Afanasjeva N, Castillo LC, Sinisterra JC (2017) Lignocellulosic biomass. Part I: biomass transformation. J Sci Tecnol Appl 3:27–43. https://doi.org/10.34294/j.jsta.17.3.22

Kumar A, Mondal P (2017) Pyrolysis of sugarcane bagasse in semi batch reactor: effects of process parameters on product yields and characterization of products. Ind Crops Prod 95:704–717. https://doi.org/10.1016/j.indcrop.2016.11.039

Sohaib Q, Muhammad A, Younas M (2017) Fast pyrolysis of locally available green waste at different residence time and temperatures. Energy Sources Part A Recovery Util Environ Effects 39:184–190. https://doi.org/10.1080/15567036.2017.1363830

Durange JA, Santos MR, Pereira MM et al (2013) Physicochemical properties of pyrolysis bio-oil from sugarcane straw and sugarcane in natura. J Biomater Nanobiotechnol 4:10–19. https://doi.org/10.4236/jbnb.2013.42A002

Palencia M (2017) Surface free energy of solids by contact angle measurements. J Sci Technol Appl 2:84–93. https://doi.org/10.34294/j.jsta.17.2.17

García-Pérez M, Chaala A, Roy C (2002) Vacuum pyrolysis of sugarcane bagasse. J Anal Appl Pyrol 65:111–136. https://doi.org/10.1016/S0165-2370(01)00184-X

Restrepo D, García A, Combatt E (2018) Infrared spectroscopy in the analysis of cation exchange capacity of soils—A review. J Sci Technol Appl 5:55–65. https://doi.org/10.34294/j.jsta.18.5.35

Palencia M, Lerma T, Berrio ME (2017) Thin-film composite by in situ polymerization of 4-chloromethyl styrene functionalized with N-methyl-D-glucamine in pore-type microreactors. J Sci Technol Appl 3:66–76. https://doi.org/10.34294/j.jsta.17.3.25

Palencia M (2018) Functional transformation of Fourier-transform mid-infrared spectrum for improving spectral specificity by simple algorithm based on wavelet-like functions. J Adv Res 14:53–62. https://doi.org/10.1016/j.jare.2018.05.009

Arbelaez N, Lerma T, Córdoba A (2017) Modification of membranes by insertion of short-chain alcohols on reactive porous substrates: effect of chain length on the surface free energy. J Sci Technol Appl 2:75–83. https://doi.org/10.34294/j.jsta.17.2.16

Sardo H, Pascual A, Mecerreyes D, Taton D, Cramail H, Hedrick J (2015) Synthesis of polyurethanes using organocatalysis: a perspective. Macromol 48:3153–3165. https://doi.org/10.1021/acs.macromol.5b00384

Wiley J, Atalla R (1987) Band assignments in the Raman spectra of celluloses. Carbohydr Res 160:113–129. https://doi.org/10.1016/0008-6215(87)80306-3

Rahman R, Hamdan S, Ngaini ZB et al (2018) Cellulose fiber-reinforced thermosetting composites: impact of cyanoethyl modification on mechanical, thermal and morphological properties. Polym Bull. https://doi.org/10.1007/s00289-018-2598-1

Miléo PC, Oliveira MF, Luz SM et al (2016) Thermal and chemical characterization of sugarcane bagasse cellulose/lignin-reinforced composites. Polym Bull 73:3163. https://doi.org/10.1007/s00289-016-1647-x

Gaan S, Rupper P, Salimova V et al (2009) Thermal decomposition and burning behavior of cellulose treated with ethyl ester phosphoramidates: Effect of alkyl substituent on nitrogen atom. Polym Degrad Stabil 94:1125–1134. https://doi.org/10.1016/j.polymdegradstab.2009.03.017

Loof D, Hiller M, Oschkinat H, Koschek K (2016) Quantitative and qualitative analysis of surface modified cellulose utilizing TGA-MS. Materials (Basel, Switzerland) 9(6):415. https://doi.org/10.3390/ma9060415

Acknowledgements

Authors thanks to Universidad del Valle by funds supplied.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Palencia, M., Mora, M.A., Lerma, T.A. et al. Reinforcing agents based on cellulose fibers modified by insertion of end-alkyl groups obtained from pyrolytic bio-oil of sugarcane bagasse. Polym. Bull. 77, 5711–5724 (2020). https://doi.org/10.1007/s00289-019-03050-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-03050-0