Abstract

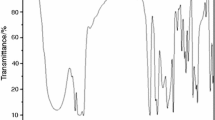

In this study, hydroxyl end functional group benzoxazine monomer (BZ-OH) was synthesized from ethanolamine, bisphenol-A and paraformaldehyde. The monomer was analysed and confirmed by Fourier transform infrared, and (1H and 13C) nuclear magnetic resonance techniques, respectively. The benzoxazine (10% by weight) was incorporated into a (50:50) weight ratio of epoxy resin and its hardener. This mixture was first cured at room temperature for 24 h and then post-cured at temperatures; 90, 120, 150, 180, 200 and 220 °C, respectively. Thermal gravimetric analysis was employed to study the effect of the different curing temperatures on the thermal properties of the benzoxazine/epoxy mixture. The results showed an overall improvement in the thermal stability of the samples as the curing temperature is increased. However, the product cured at 220 °C depicted a better thermal behaviour, with a decomposition temperature in the range of 258–532 °C.

Similar content being viewed by others

References

Tesoro G (1988) Epoxy resins-chemistry and technology, 2nd Edition, Clayton A. May, Ed., Marcel Dekker, New York, 1988, 1,288 pp. Price: $195.00. J Polym Sci Part C: Polym Lett 26(12):539–539

Campana C et al (2018) Effect of post curing temperature on mechanical properties of a flax fiber reinforced epoxy composite. Compos Part A: Appl Sci Manuf 107:171–179

Al Shaabania YA (2019) Wear and friction properties of epoxy-polyamide blend nanocomposites reinforced by MWCNTs. Energy Procedia 157:1561–1567

Chou TY, Tsai H-Y, Yip MC (2019) Preparation of CFRP with modified MWCNT to improve the mechanical properties and torsional fatigue of epoxy/polybenzoxazine copolymer. Compos Part A: Appl Sci Manuf 118:30–40

Jiang M et al (2018) Enhanced mechanical and thermal properties of monocomponent high performance epoxy resin by blending with hydroxyl terminated polyethersulfone. Polym Test 69:02–309

Kishi H, Yamada K, Kimura J (2019) Control of nanostructures and fracture toughness of epoxy/acrylic block copolymer blends using in situ manipulation of the epoxy matrix reaction type. Polymer 176:89–100

Siebert AR (1984) Morphology and dynamic mechanical behavior of rubber-toughened epoxy resins. In: Rubber-modified thermoset resins, vol 208. American Chemical Society, pp 179–191

An H et al (2019) Thermal behaviors of nanoparticle reinforced epoxy resins for microelectronics packaging. Microelectron Reliab 93:39–44

Arash B, Exner W, Rolfes R (2019) Viscoelastic damage behavior of fiber reinforced nanoparticle-filled epoxy nanocomposites: multiscale modeling and experimental validation. Compos Part B: Eng 174:107005

Lila, M.K., et al. (2018) Effect of environmental conditioning on natural fiber reinforced epoxy composites. Mater Today: Proc 5(9, Part 1):17006–17011.

Okhawilai M, Hiziroglu S, Rimdusit S (2018) Measurement of ballistic impact performance of fiber reinforced polybenzoxazine/polyurethane composites. Measurement 130:198–210

Sarikaya E, Çallioğlu H, Demirel H (2019) Production of epoxy composites reinforced by different natural fibers and their mechanical properties. Compos Part B: Eng 167:461–466

Burke, W.J. (1949) 3,4-Dihydro-1,3,2H-benzoxazines. Reaction of p-substituted Phenols with N,N-Dimethylolamines. J Am Chem Soc 71(2):609–612.

Zhang K, Shang Z (2019) Chapter 5—Polybenzoxazine: a smart polymer for novel environmental and catalytic applications. In: Li S, et al. (eds) Smart polymer catalysts and tunable catalysis. Elsevier, Amsterdam, pp 95–114

Ghosh NN, Kiskan B, Yagci Y (2007) Polybenzoxazines—new high performance thermosetting resins: synthesis and properties. Prog Polym Sci 32(11):1344–1391

Ishida H, Low HY (1997) A study on the volumetric expansion of benzoxazine-based phenolic resin. Macromolecules 30(4):1099–1106

Takeichi T, Kawauchi T, Agag T (2008) High performance polybenzoxazines as a novel type of phenolic resin. Polym J 40:1121

Yagci Y, Kiskan B, Ghosh NN (2009) Recent advancement on polybenzoxazine—a newly developed high performance thermoset. J Polym Sci Part A: Polym Chem 47(21):5565–5576

Ishida H, P.F. (2017) Advanced and emerging polybenzoxazine science and technology. Elsevier, Amsterdam

Ishida H, Allen DJ (1996) Mechanical characterization of copolymers based on benzoxazine and epoxy. Polymer 37(20):4487–4495

Mittal KL, Pizzi A (2018) Handbook of adhesive technology, 3rd edn. CRC Press, Boca Raton

Rimdusit S, Jubsilp C, Tiptipakorn S (2013) Polybenzoxazine alloys. In: Rimdusit S, Jubsilp C, Tiptipakorn S (eds) Alloys and composites of polybenzoxazines: properties and applications. Springer, Singapore, pp 29–46

Vengatesan MR et al (2012) SBA-15 filled polybenzoxazine nanocomposites for low-k dielectric applications. J Mater Chem 22(15):7559–7566

Gilbert E et al (2018) Design of thermosetting polymeric systems based on benzoxazines modified with maleic anhydride. J Appl Polym Sci 135(17):46183

Asiri AM et al (2015) Enhanced coating properties of Ni-La-ferrites/epoxy resin nanocomposites. Polym Compos 36(10):1875–1883

Asiri AM et al (2013) Effect of NiLaxFe2− xO4 nanoparticles on the thermal and coating properties of epoxy resin composites. Compos Part B: Eng 51:11–18

Hussein MA, Abu-Zied BM, Asiri AM (2016) The role of mixed graphene/carbon nanotubes on the coating performance of G/CNTs/Epoxy resin nanocomposites. Int J Electrochem Sci 11:7644–7659

Hussein MA, Abu-Zied BM, Asiri AM (2018) Fabrication of EPYR/GNP/MWCNT carbon-based composite materials for promoted epoxy coating performance. RSC Adv 8(42):23555–23566

Ishida H, Agag T (2011) Handbook of benzoxazine resins. Elsevier, Amsterdam

Jubsilp C, Ramsiri B, Rimdusit S (2012) Effects of aromatic carboxylic dianhydrides on thermomechanical properties of polybenzoxazine-dianhydride copolymers. Polym Eng Sci 52(8):1640–1648

Han L et al (2017) Oxazine ring-related vibrational modes of benzoxazine monomers using fully aromatically substituted, deuterated, 15N isotope exchanged, and oxazine-ring-substituted compounds and theoretical calculations. J Phys Chem A 121(33):6269–6282

Chutayothin P, Ishida H (2009) 31P NMR spectroscopy in benzoxazine model compounds and benzoxazine chemistry–main chain and end group studies. Eur Polym J 45(5):1493–1505

Ning X, Ishida H (1994) Phenolic materials via ring-opening polymerization of benzoxazines: Effect of molecular structure on mechanical and dynamic mechanical properties. J Polym Sci Part B: Polym Phys 32(5):921–927

Ramos VD et al (2005) Modification of epoxy resin: a comparison of different types of elastomer. Polym Test 24(3):387–394

Mimura K, Ito H, Fujioka H (2000) Improvement of thermal and mechanical properties by control of morphologies in PES-modified epoxy resins. Polymer 41(12):4451–4459

Deng P et al (2018) Solidifying process and flame retardancy of epoxy resin cured with boron-containing phenolic resin. Appl Surf Sci 427:894–904

Shukla S et al (2016) Kinetics behind a strategy for modulation of sustainable benzoxazines: experimental study and its theoretical verification. Macromol Chem Phys 217(12):1342–1353

Deshpande N et al (2019) Epoxide ring opening with alcohols using heterogeneous Lewis acid catalysts: regioselectivity and mechanism. J Catal 370:46–54

Zhang J et al (2019) Toughening benzoxazine/epoxy thermosets through control of interfacial interactions and morphologies by hyperbranched polymeric ionic liquids. J Mol Liq 291:111251

Park S-J, Jin F-L (2004) Thermal stabilities and dynamic mechanical properties of sulfone-containing epoxy resin cured with anhydride. Polym Degrad Stab 86(3):515–520

Rajesh Kumar S, Dhanasekaran J, Krishna Mohan S (2015) Epoxy benzoxazine based ternary systems of improved thermo-mechanical behavior for structural composite applications. RSC Adv 5(5):3709–3719

Peng C et al (2018) Synthesis and application of a benzoxazine-type phosphorus-containing monomer on epoxy/benzoxazine copolymer: thermal stability and compatibility with liquid oxygen. Polym Degrad Stab 157:131–142

Liu Y et al (2011) Thermal degradation behavior and kinetics of polybenzoxazine based on bisphenol-S and aniline. Thermochim Acta 523(1):170–175

Ertas Y, Uyar T (2016) Cross-linked main-chain polybenzoxazine nanofibers by photo and thermal curing; stable at high temperatures and harsh acidic conditions. Polymer 84:72–80

Acknowledgements

This work was supported by the Deanship of Scientific Research (DSR), king Abdulaziz University, Jeddah, under Grant No. (DG-042–130-1440). The authors, therefore, gratefully acknowledge the DSR technical and financial support.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Musa, A., Alamry, K.A. & Hussein, M.A. The effect of curing temperatures on the thermal behaviour of new polybenzoxazine-modified epoxy resin. Polym. Bull. 77, 5439–5449 (2020). https://doi.org/10.1007/s00289-019-03026-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-03026-0