Abstract

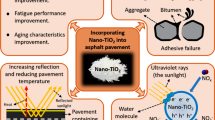

Green road concept encourages optimum utilization of local resources as one of the important indicators of the sustainable development. The form of re-utilization of material is economic and environmentally friendly. In this research, environmentally friendly green asphalt was prepared for road construction by mixing with waste poly(ethylene terephthalate) (WPET). This work starts with glycolysis of WPET followed by synthesis of unsaturated polyester (UP). Different types of glycols, namely diethylene glycol, triethylene glycol and propylene glycol, were used and blended with asphalt binder to obtain an eco-friendly modifier of asphalt 60/70. The modifiers were used in percentages of 4% and 8% (wt/wt) to obtain modified asphalt binder with desirable physical and engineering properties. The prepared UPs were characterized using FTIR, GPC and TGA. The prepared modified asphalt samples were evaluated for physical, chemical, colloidal stability, TGA and rutting resistance using dynamic shear rheometer. The results showed an improvement in asphalt properties which became more thermal stable, resistant to rutting and plastic deformation causing the susceptibility of asphalt to operate in different climates which means obtaining eco-friendly green asphalt with enhanced dynamic mechanical properties.

Similar content being viewed by others

References

Mulmi AD (2009) Green road approach in rural road construction for the sustainable development of Nepal. J Sustain Dev 2(3):149

Ji LN (2013) Study on preparation process and properties of polyethylene terephthalate (PET). Appl Mech Mater 312:406–410. https://doi.org/10.4028/www.scientific.net/AMM.312.406

Leng Z, Sreeram A, Padhan RK, Tan Z (2018) Value-added application of waste PET based additives in bituminous mixtures containing high percentage of reclaimed asphalt pavement (RAP). J Clean Prod 196:615–625

Sarker M, Rashid MM (2013) Thermal degradation of poly(ethylene terephthalate) waste soft drinks bottles and low density polyethylene grocery bags. Int J Sustain Energy Environ 1:78–86

Luo X, Li Y (2014) Synthesis and characterization of polyols and polyurethane foams from PET waste and crude glycerol. J Polym Environ 22(3):318–328

Vaidya UR, Nadkarni VM (1987) Unsaturated polyesters from PET waste: kinetics of polycondensation. J Appl Polym Sci 34(1):235–245

Patel MR, Patel JV, Mishra D, Sinha VK (2007) Synthesis and characterization of low volatile content polyurethane dispersion from depolymerised polyethylene terphthalate. J Polym Environ 15(2):97–105

Pingale ND, Palekar VS, Shukla SR (2010) Glycolysis of postconsumer polyethylene terephthalate waste. J Appl Polym Sci 115(1):249–254

Sinha V, Patel MR, Patel JV (2010) PET waste management by chemical recycling: a review. J Polym Environ 18(1):8–25

Ahmadinia E, Zargar M, Karim MR, Abdelaziz M, Shafigh P (2011) Using waste plastic bottles as additive for stone mastic asphalt. Mater Des 32(10):4844–4849

Garcia-Morales M, Partal P, Navarro FJ, Gallegos C (2006) Effect of waste polymer addition on the rheology of modified bitumen. Fuel 85(7–8):936–943

Ameri M, Nasr D (2016) Properties of asphalt modified with devulcanized polyethylene terephthalate. Pet Sci Technol 34(16):1424–1430

Sulyman M, Haponiuk J, Formela K (2016) Utilization of recycled polyethylene terephthalate (PET) in engineering materials: a review. Int J Environ Sci Dev 7(2):100

Padhan RK, Gupta AA, Badoni RP, Bhatnagar AK (2013) Poly(ethylene terephthalate) waste derived chemicals as an antistripping additive for bitumen—An environment friendly approach for disposal of environmentally hazardous material. Polym Degrad Stab 98(12):2592–2601

Gürü M, Çubuk MK, Arslan D, Farzanian SA, Bilici I (2014) An approach to the usage of polyethylene terephthalate (PET) waste as roadway pavement material. J Hazard Mater 279:302–310

Yang P, Cong Q, Liao K (2003) Application of solubility parameter theory in evaluating the aging resistance of paving asphalts. Pet Sci Technol 21(11–12):1843–1850

Oyekunle LO (2006) Certain relationships between chemical composition and properties of petroleum asphalts from different origin. Oil Gas Sci Technol Revue de l’IFP 61(3):433–441

Oliver JWH (2009) Changes in the chemical composition of Australian bitumens. Road Mater Pavement Des 10(3):569–586

Paliukaite M, Vaitkus A, Zofka A (2014) Evaluation of bitumen fractional composition depending on the crude oil type and production technology. In: Environmental engineering. Proceedings of the international conference on environmental engineering. ICEE, vol 9. Vilnius Gediminas Technical University, Department of Construction Economics and Property, p 1

ASTM D5 (2013) Standard test method for penetration of bituminous materials, vol 04-03. ASTM International, West Conshohocken. www.astm.org

ASTM D36 (2014) Standard test method for softening point of bitumen (ring-and-ball apparatus), vol 04-03. ASTM International, West Conshohocken. www.astm.org

ASTM D113 (2017) Standard test method for ductility of asphalt materials, vol 04-03. ASTM International, West Conshohocken. www.astm.org

ASTM E2550 (2017) Standard test method for thermal stability by thermogravimetry, vol 04-03. ASTM International, West Conshohocken. www.astm.org

AASHTO (2012) Standard method of test for determining the rheological properties of asphalt binder using a dynamic shear rheometer (DSR). American Association of State and Highway Transportation Officials

Moghaddam TB, Soltani M, Karim MR (2014) Evaluation of permanent deformation characteristics of unmodified and polyethylene terephthalate modified asphalt mixtures using dynamic creep test. Mater Des 53:317–324

Tahvildari K, Mozafari S, Tarinsun N (2010) Chemical recycling of poly ethylene terphthalat to obtain unsaturated polyester resins. J Appl Chem Res 12:59–68

Abdelaal MY, Sobahi TR, Makki MSI (2011) Chemical transformation of PET waste through glycolysis. Constr Build Mater 25(8):3267–3271

Siggia S, Hanna JG (1978) Quantitative organic analysis via functional groups. Wiley, Hoboken

ASTM D4662 (2015) Standard test methods for polyurethane raw materials: determination of acid and alkalinity numbers of polyols, vol 08-02. ASTM International, West Conshohocken. www.astm.org

Nikles DE, Farahat MS (2005) New motivation for the depolymerization products derived from poly(ethylene terephthalate) (PET) waste: a review. Macromol Mater Eng 290(1):13–30

Mothé MG, Leite LF, Mothé CG (2008) Thermal characterization of asphalt mixtures by TG/DTG, DTA and FTIR. J Therm Anal Calorim 93(1):105–109

Al-Khateeb GG, Ramadan KZ (2015) Investigation of the effect of rubber on rheological properties of asphalt binders using superpave DSR. KSCE J Civ Eng 19(1):127–135

AASHTO, T315 (2012) Standard method of test for determining the rheological properties of asphalt binder using a dynamic shear rheometer (DSR)

Al-Sabagh AM, Yehia FZ, Eshaq G, Rabie AM, ElMetwally AE (2016) Greener routes for recycling of polyethylene terephthalate. Egypt J Pet 25(1):53–64

Atta AM, Abdel-Raouf ME, Elsaeed SM, Abdel-Azim AAA (2007) Mechanical characterization and chemical resistances of cured unsaturated polyester resins modified with vinyl ester resins based on recycled poly(ethylene terephthalate). J Appl Polym Sci 103(5):3175–3182

Ragab AA, Farag RK, Kandil UF, El-Shafie M, Saleh AMM, El-Kafrawy AF (2016) Thermo-mechanical properties improvement of asphalt binder by using methylmethacrylate/ethylene glycol dimethacrylate. Egypt J Pet 25(3):397–407

Ehinola OA, Falode OA, Jonathan G (2012) Softening point and Penetration Index of bitumen from parts of Southwestern Nigeria. Nafta 63(9–10):319–323

Leng Z, Padhan RK, Sreeram A (2018) Production of a sustainable paving material through chemical recycling of waste PET into crumb rubber modified asphalt. J Clean Prod 180:682–688

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abdel Bary, E.M., Farag, R.K., Ragab, A.A. et al. Green asphalt construction with improved stability and dynamic mechanical properties. Polym. Bull. 77, 1729–1747 (2020). https://doi.org/10.1007/s00289-019-02821-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02821-z