Abstract

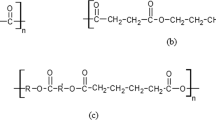

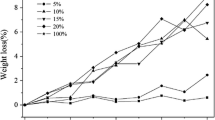

Pectin has now become cynosure among all the others because of an unusual combination of biological activities, mechanical and physical properties. The present work comprises the chemical modification of pectin by grafting of vinyl monomers, i.e., tert-butyl acrylate and methacrylamide in a homogeneous aqueous phase using ceric ammonium nitrate as the initiator. All these three variants of pectin and modified pectin (10–30%) were blended with low-density polyethylene in various compositions using twin-screw extruder machine. Low-density polyethylene was grafted with maleic anhydride and subsequently used as a compatibilizer (5 and 10%) to promote the interfacial interaction between the ingredients. The characterization of the grafted products was confirmed by Fourier transform infrared spectroscopy, and percentage grafting G (%), percentage efficiency E (%) and yield of graft copolymerization Y (%) were determined. The sample blends were prepared by automatic injection molding machine, and blends were subjected to mechanical properties, scanning electron microscopy, thermal gravimetric analysis and biodegradation study.

Similar content being viewed by others

References

Habil Roper H, Koch H (1990) The role of starch in biodegradable thermoplastic materials. Starch Starke 42:123. https://doi.org/10.1002/star.19900420402

Kyrikou I, Briassoulis D (2007) Biodegradation of agricultural plastic films: a critical review. J Polym Environ 15:125. https://doi.org/10.1007/s10924-007-0053-8

Gulmine JV, Janissek PR, Heise HM, Akcelrud L (2003) Degradation profile of polyethylene after artificial accelerated weathering. Polym Degrad Stab 79:385–397. https://doi.org/10.1016/S0141-3910(02)00338-5

Wiles DM, Scott G (2006) Polyolefins with controlled environmental degradability. Polym Degrad Stab 91:1581–1592. https://doi.org/10.1016/j.polymdegradstab.2005.09.010

Ammala A, Bateman S, Dean K, Petinakis E, Sangwan P, Wong S, Yuan Q, Yu L, Patrick C, Leong KH (2011) An overview of degradable and biodegradable polyolefins. Prog Polym Sci 36:1015. https://doi.org/10.1016/j.progpolymsci.2010.12.002

Heinze T, Liebert T (2001) Unconventional methods in cellulose functionalization. Prog Polym Sci 26:1689. https://doi.org/10.1016/S0079-6700(01)00022-3

Fanta GF, Doane WM (1986) Grafted starches. In: Wurzburg OB (ed) Modified starches: properties and uses. CRC Press, Boca Raton, pp 149–178

Okieimen FE, Ogbeifun DE (1996) Graft copolymerizations of modified cellulose: grafting of methyl acrylate, ethyl acrylate and ethyl methacrylate on carboxy methyl cellulose. Eur Polym J 32:311. https://doi.org/10.1016/0014-3057(95)00152-2

Okieimen FE (1998) Graft copolymerization of vinyl monomers on cellulosic materials. Angew Makromol Chem Angew Makromol Chem 260(1):5–10. https://doi.org/10.1002/(SICI)1522-9505(19981101)260:1%3c5:AID-APMC5%3e3.0.CO;2-W

Okieimen FE, Ogbeifun DE (1996) Graft copolymerizations of modified cellulose, grafting of acrylonitrile, and methyl methacrylate on carboxy methyl cellulose. J Appl Polym Sci 59:981. https://doi.org/10.1002/(SICI)1097-4628(19960207)59:6%3c981:AID-APP11%3e3.0.CO;2-Q

Deshmukh SR, Sudhakar K, Singh RP (1991) Drag-reduction efficiency, shear stability, and biodegradation resistance of carboxymethyl cellulose-based and starch-based graft copolymers. J Appl Polym Sci 43:1091–1101. https://doi.org/10.1002/app.1991.070430609

Okieimen FE (2003) Preparation, characterization, and properties of cellulose–polyacrylamide graft copolymers. J Appl Polym Sci 89:913. https://doi.org/10.1002/app.12014

Leza ML, Casinos I, Guzman GM (1989) Graft copolymerization of 4-vinylpyridine onto cellulosics effect of temperature. Eur Polym J 25:1193–1196. https://doi.org/10.1016/0014-3057(89)90080-3

Willett JL (1994) Mechanical properties of LDPE/granular starch composites. J Appl Polym Sci 54:1685. https://doi.org/10.1002/app.1994.070541112

Vaidya UR, Bhattacharya M (1994) Properties of blends of starch and synthetic polymers containing anhydride groups. J Appl Polym Sci 52:617. https://doi.org/10.1002/app.1994.070520505

Prinos J, Bikiaris D, Theologidis S, Panayiotou C (1998) Preparation and characterization of LDPE/starch blends containing ethylene/vinyl acetate copolymer as compatibilizer. Polym Eng Sci 38:954. https://doi.org/10.1002/pen.10263

Bikiaris D, Panayiotou C (1998) LDPE/starch blends compatibilized with PE-g-MA copolymers. J Appl Polym Sci 70:1503. https://doi.org/10.1002/(SICI)1097-4628(19981121)70:8%3c1503:AID-APP9%3e3.0.CO;2-%23

Sailaja RRN, Chanda M (2001) Use of maleic anhydride–grafted polyethylene as compatibilizer for HDPE–tapioca starch blends: effects on mechanical properties. J Appl Poym Sci 80:863. https://doi.org/10.1002/1097-4628(20010509)80:6%3c863:AID-APP1164%3e3.0.CO;2-R

Griffin GJL (1994) Starch polymer blends. Polym Degrad Stab 45:241–247. https://doi.org/10.1016/0141-3910(94)90141-4

Kim M, Lee S-J (2002) Characteristics of crosslinked potato starch and starch-filled line ar low-density polyethylene films. Carbohydr Polym 50:331–537. https://doi.org/10.1016/S0144-8617(02)00057-7

Kiatkamjornwong S, Thakeow P, Sonsuk M (2001) Chemical modification of cassava starch for degradable polyethylene sheets. Polym Degrad Stab 73:363–375. https://doi.org/10.1016/S0141-3910(01)00100-8

Fang JM, Fowler PA, Tomkinson J, Hill CAS (2002) The preparation and characterisation of a series of chemically modified potato starches. Carbohydr Polym 47:245. https://doi.org/10.1016/S0144-8617(01)00187-4

Abdul Khalil HPS, Chow WC, Rozman HD, Ismail H, Ahmad MN, Kumar RN (2001) The effect of anhydride modification of sago starch on the tensile and water absorption properties of sago-filled linear low-density polyethylene. Polym Plast Technol Eng 40:249–263. https://doi.org/10.1081/PPT-100000246

Yoo SI, Lee TY, Yoon J-S, Lee I-M, Kim M-N, Lee HS (2002) Interfacial adhesion reaction of polyethylene and starch blends using maleated polyethylene reactive compatibilizer. J Appl Polym Sci 83:767. https://doi.org/10.1002/app.2271

Girija BG, Sailaja RRN (2006) Low-density polyethylene/plasticized tapioca starch blends with the low-density polyethylene functionalized with maleate ester: mechanical and thermal properties. J Appl Polym Sci 101:1109. https://doi.org/10.1002/app.24025

Garg S, Jana AK (2007) Studies on the properties and characteristics of starch–LDPE blend films using cross-linked, glycerol modified, cross-linked and glycerol modified starch. Eur Polym J 43:3976–3987. https://doi.org/10.1016/j.eurpolymj.2007.06.030

Wang YJ, Liu W, Sun Z (2004) Effects of glycerol and PE-g-MA on morphology, thermal and tensile properties of LDPE and rice starch blends. J Appl Polym Sci 92:344. https://doi.org/10.1002/app.20015

Umar A, AbuNaim A, Sanagi MM (2014) Synthesis and characterization of chitosan grafted with polystyrene using ammonium persulfate initiator. Mater Lett 124:12–14. https://doi.org/10.1016/j.matlet.2014.03.007

Broido A (1969) A simple, sensitive graphical method of treating thermogravimetric analysis data. J Polym Sci Part A 2 Polym Phys 27:1761. https://doi.org/10.1002/pol.1969.160071012

Acknowledgements

Two of the authors Ravikumar Savaliya and Sagar Joshi are thankful to the Department of Science and Technology (DST), New Delhi, India, for awarding INSPIRE Fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Raj, M., Savaliya, R., Joshi, S. et al. Biodegradability, thermal, chemical, mechanical and morphological behavior of LDPE/pectin and LDPE/modified pectin blend. Polym. Bull. 76, 5173–5195 (2019). https://doi.org/10.1007/s00289-018-2623-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-018-2623-4