Abstract

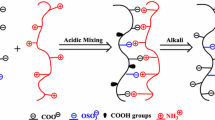

Using a solution technique, polyelectrolyte complex (PEC) membranes were prepared by the complexation of sodium alginate (SA) with gelatin (Ge). The physico-chemical properties of these PEC membranes were studied by Fourier transform infrared spectroscopy (FTIR), wide-angle X-ray diffraction (WAXD), differential scanning calorimetry (DSC), thermogravimetric analysis (TGA) and scanning electron microscopy (SEM). The pervaporation characteristics of membranes were investigated with water–isopropanol mixtures. The effects of Ge content and feed compositions on the pervaporation performance of the membranes were analyzed. The data thus obtained were employed to explain permeation behavior of water and isopropanol through PEC membranes. The experimental results showed that the membrane containing 10 mass% of Ge exhibits the highest separation selectivity of 4277 with a flux of 8.47 × 10−2 kg/m2 h at 30 °C for 10 mass% of water in the feed. The total flux and flux of water are found to be overlapping each other, particularly, for PEC membranes, manifesting that the developed membranes could be used effectively to break the azeotropic point of water–isopropanol mixtures. From the temperature dependent diffusion and permeation values, the Arrhenius activation parameters were estimated. The activation energy values obtained for water permeation (E pw) are significantly lower than those of isopropanol permeation (E pIPA), suggesting that the Ge-incorporated membranes have higher separation ability for water–isopropanol system. The negative heat of sorption (∆H s) values was obtained for all the membranes, suggesting that Langmuir’s mode of sorption is predominant.

Similar content being viewed by others

Abbreviations

- M w :

-

Molecular weight

- A :

-

Effective membrane area (m2)

- DS:

-

Degree of swelling (%)

- D 0 :

-

Pre-exponential factor for diffusion

- E D :

-

Activation energy for diffusion (kJ/mol)

- E Dw :

-

Activation energy for diffusion of water (kJ/mol)

- E p :

-

Activation energy for permeation (kJ/mol)

- E pw :

-

Activation energy for permeation of water (kJ/mol)

- E DIPA :

-

Activation energy for diffusion of IPA (kJ/mol)

- E x :

-

Activation energy for permeation or diffusion (kJ/mol)

- ∆H s :

-

Heat of sorption (kJ/mol)

- IPA:

-

Isopropanol

- J :

-

Total flux (kg/m2 h)

- J 0 :

-

Pre-exponential factor for permeation

- PSI:

-

Pervaporation separation index

- P and F :

-

Mass percent of permeate and feed

- R :

-

Gas constant

- t :

-

Permeation time (h)

- T :

-

Temperature (K)

- W :

-

Mass of permeate (kg)

- W s and W d :

-

Mass of the swollen and dry membranes

- δ :

-

Membrane thickness (45 μm)

- α sep :

-

Separation factor

References

Mulder M (1998) Basic principles of membrane technology, 2nd edn. Kluwer Academic, Netherlands

Rezakazemi M, Razavi S, Mohammadi T, Nazari AG (2011) Simulation and determination of optimum conditions of pervaporative dehydration of isopropanol process using synthesized PVA-APTEOS/TEOS nanocomposite membranes by means of expert systems. J Membr Sci 379:224–232

Zhang QG, Liu QL, Chen Y, Chen JH (2007) Dehydration of isopropanol by novel poly(vinyl alcohol)-silicone hybrid membranes. Ind Eng Chem Res 46:913–920

Panek D, Konieczny K (2007) Preparation and applying the membranes with carbon black to pervaporation of toluene from the diluted aqueous solutions. Sep Purif Technol 57:507–512

Shao P, Huang RYM (2007) Polymeric membrane pervaporation. J Membr Sci 287:162–179

Sajjan AM, Premakshi HG, Kariduraganavar MY (2015) Synthesis and characterization of GTMAC grafted chitosan membranes for the dehydration of low water content isopropanol by pervaporation. J Ind Eng Chem 25:151–161

Sajjan AM, Kariduraganavar MY (2013) Development of novel membranes for PV separation of water–isopropanol mixtures using poly(vinyl alcohol) and gelatin. J Membr Sci 438:8–17

Liu YL, Yu CH, Lee KR, Lai JY (2007) Chitosan poly(tetrafluoroethylene) composite membranes using in pervaporation dehydration processes. J Membr Sci 287:230–236

Rao PS, Sridhar S, Wey MY, Krishnaiah A (2006) Pervaporative separation of ethylene glycol/water mixtures by using cross-linked chitosan membranes. Ind Eng Chem Res 46:2155–2163

Zhao Q, Qian JW, An QF, Zhu ZH, Zhang P, Bai YX (2008) Studies on pervaporation characteristics of polyacrylonitrile-b-poly(ethylene glycol)-b-polyacrylonitrile block copolymer membrane for dehydration of aqueous acetone solutions. J Membr Sci 311:284–293

Qiao XY, Chung TS (2005) Fundamental characteristics of sorption, swelling, and permeation of P84 co-polyimide membranes for pervaporation dehydration of alcohols. Ind Eng Chem Res 44:8938–8943

Sato K, Nakane T (2007) A high reproducible fabrication method for industrial production of high flux NaA zeolite membrane. J Membr Sci 301:151–161

Ahn H, Lee H, Lee SB, Lee Y (2007) Dehydration of TFEA/water mixture through hydrophilic zeolite membrane by pervaporation. J Membr Sci 291:46–52

Sairam M, Patil MB, Veerapur RS, Patil SA, Aminabhavi TM (2006) Novel dense poly(vinyl alcohol)-TiO2 mixed matrix membranes for pervaporation separation of water–isopropanol mixtures at 30 °C. J Membr Sci 281:95–102

Liu YL, Hsu CY, Su YH, Lai JY (2005) Chitosan–silica complex membranes from sulfonic acid functionalized silica nanoparticles for pervaporation dehydration of ethanol–water solutions. Biomacromol 6:368–373

Huang Z, Guan HM, Tan WL, Qiao XY, Kulprathipanja S (2006) Pervaporation study of aqueous ethanol solution through zeolite-incorporated multilayer poly(vinyl alcohol) membranes: effect of zeolites. J Membr Sci 276:260–271

Zhang P, Qian JW, Yang Y, An QF, Liu XQ, Gui ZL (2008) Polyelectrolyte layer-by-layer self-assembly enhanced by electric field and their multilayer membranes for separating isopropanol–water mixtures. J Membr Sci 320:73–77

Krasemann L, Tieke B (1998) Ultrathin self-assembled polyelectrolyte membranes for pervaporation. J Membr Sci 150:23–30

Jochen MH, Wolfgang L, Dieter L, Lunkwitz K (2001) Pervaporation separation of water/alcohol mixtures using composite membranes based on polyelectrolyte multilayer assemblies. J Membr Sci 184:233–243

Zhang GJ, Yan HH, Ji SL, Liu ZZ (2007) Self-assembly of polyelectrolyte multilayer pervaporation membranes by a dynamic layer-by-layer technique on a hydrolyzed polyacrylonitrile. J Membr Sci 292:1–8

Zhao Q, Qian JW, An QF, Yang Q, Zhang P (2008) A facile route for fabricating novel polyelectrolyte complex membrane with high pervaporation performance in isopropanol dehydration. J Membr Sci 320:8–12

Zhao Q, Qian J, An Q, Gui Z, Jin H, Yin M (2009) Pervaporation dehydration of isopropanol using homogeneous polyelectrolyte complex membranes of poly(diallyldimethylammonium chloride)/sodium carboxymethyl cellulose. J Membr Sci 329:175–182

Kim SG, Lee KS, Lee KH (2007) Pervaporation separation of sodium alginate/chitosan polyelectrolyte complex composite membrane for the separation of water/alcohol mixtures: characterization of the permeation behaviour with molecular modeling techniques. J Appl Polym Sci 103:2634–2641

Thunemann AF, Muller M, Dautzenberg H, Joanny JF, Luwen H (2004) Polyelectrolyte complexes. Adv Polym Sci 166:113–171

Ngah WSW, Fatinathan S (2008) Adsorption of Cu(II) ions in aqueous solution using chitosan beads, chitosan–GLA beads and chitosan–alginate beads. Chem Eng J 143:62–72

Xu SW, Jiang ZY, Lu Y, Wu H, Yuan WK (2006) Preparation and catalytic properties of novel alginate–silica–dehydrogenase hybrid biocomposite beads. Ind Eng Chem Res 45:511–517

Kalyani S, Smitha B, Sridhar S, Krishnaiah A (2006) Separation of ethanol–water mixtures by pervaporation using sodium alginate/poly(vinyl pyrrolidone) blend membranes crosslinked with phosphoric acid. Ind Eng Chem Res 45:9088–9095

Soradech S, Nunthanid J, Limmatvapirat S, Anan ML (2012) An approach for the enhancement of the mechanical properties and film coating efficiency of shellac by the formation of composite films based on shellac and gelatin. J. Food Engineering 108:94–102

Yoshikawa M, Higuchi A, Ishikawa M, Guiver MD, Robertson GP (2004) Vapor permeation of aqueous 2-propanol solutions through gelatin/torlon((R)) poly(amide imide) blended membranes. J Membr Sci 243:89–95

Dong ZF, Wang Q, Du YM (2006) Alginate/gelatin blend films and their properties for drug controlled release. J Membr Sci 280:37–44

Isiklan N (2006) Controlled release of insecticide carbaryl from sodium alginate, sodium alginate/gelatin, and sodium alginate/sodium carboxymethyl cellulose blend beads crosslinked with glutaraldehyde. J Appl Polym Sci 99:1310–1319

Sajjan AM, Jeevan Kumar BK, Kittur AA, Kariduraganavar MY (2013) Novel approach for the development of pervaporation membranes using sodium alginate and chitosan-wrapped multiwalled carbon nanotubes for the dehydration of isopropanol. J Membr Sci 425–426:77–88

Sajjan AM, Jeevan Kumar BK, Kittur AA, Kariduraganavar MY (2013) Development of novel grafted hybrid PVA membranes using glycidyltrimethylammonium chloride for pervaporation separation of water–isopropanol mixtures. J Ind Eng Chem 19:427–437

Fan L, Du Y, Huang R, Wang Q, Wang X, Zhang L (2005) Preparation and characterization of alginate/gelatin blend fibres. J Appl Polym Sci 96:1625–1629

Liu SZ, Wang F, Chen TL (2001) Synthesis of poly(ether ether ketones) with high content of sodium sulfonate groups as gas dehumidification membrane materials. Macromol Rapid Comm 22:579–582

Bigi A, Panzavolta S, Rubini K (2004) Relationship between triple-helix content mechanical properties of gelatin films. Biomaterials 25:5675–5680

Chen S, Liu M, Jin S, Chen Y (2007) Structure and properties of the polyelectrolyte complex of chitosan with poly(methacrylic acid). Polym Int 56:1305–1312

Honma I, Nishikawa O, Sugimoto T, Nomura S, Nakajima H (2002) A sol–gel derived organic-inorganic hybrid membrane for intermediate temperature PEFC. Fuel Cells 2:52–58

Kurkuri MD, Toti US, Aminabhavi TM (2002) Syntheses and characterization of blend membranes of sodium alginate and poly(vinyl alcohol) for the pervaporation separation of water–isopropanol mixtures. J Appl Polym Sci 86:3642–3651

Saraswathi M, Rao KM, Prabhakar MN, Prasad CV, Sudakar K, Kumar HMPN, Prasad M, Rao KC, Subha MCS (2011) Pervaporation studies of sodium alginate (SA)/dextrin blend membranes for separation of water and isopropanol mixture. Desalination 269:177–183

Toti US, Aminabhavi TM (2002) Pervaporation separation of water–isopropyl alcohol mixtures with blend membranes of sodium alginate and poly(acrylamide)-grafted guar gum. J Appl Polym Sci 85:2014–2024

Toti US, Aminabhavi TM (2004) Different viscosity grade sodium alginate and modified sodium alginate membranes in pervaporation separation of water + acetic acid and water + isopropanol mixtures. J Membr Sci 228:199–208

Bhat SD, Naidu BVK, Shanbhag GV, Halligudi SB, Sairam M, Aminabhavi TM (2006) Mesoporous molecular sieve (MCM-41)-filled sodium alginate hybrid nanocomposite membranes for pervaporation separation of water–isopropanol mixtures. Sep Purif Technol 49:56–63

Bhat SD, Aminabhavi TM (2006) Novel sodium alginate composite membranes incorporated with SBA-15 molecular sieves for the pervaporation dehydration of aqueous mixtures of isopropanol and 1,4-dioxane at 30 °C. Micropor Mesopor Mater 91:206–214

Bhat SD, Aminabhavi TM (2006) Novel sodium alginate-Na+MMT hybrid composite membranes for pervaporation dehydration of isopropanol, 1,4-dioxane and tetrahydrofuran. Sep Purif Technol 51:85–94

Kariduraganavar MY, Kittur AA, Kulkarni SS, Ramesh K (2004) Development of novel pervaporation membranes for the separation of water–isopropanol mixtures using sodium alginate and NaY zeolite. J Membr Sci 238:165–175

Kulkarni SS, Tambe SM, Kittur AA, Kariduraganavar MY (2006) Modification of tetraethylorthosilicate crosslinked poly(vinyl alcohol) membrane using chitosan and its application to the pervaporation separation of water–isopropanol mixtures. J Appl Polym Sci 99:1380–1389

Hwang ST, Kammermeyer K (1975) Membrane in separation. Wiley-Interscience, New York

Cabasso I, Jagu-Grodzinski J, Vofsi D (1974) A study of permeation of organic solvents through polymeric membranes based on polymeric alloys of polyphosphonates and acetyl cellulose. II. Separation of benzene, cyclohexene and cyclohexane. Appl Polym Sci 18:2137–2147

Yamasaki A, Iwatsubo T, Masuoka T, Mizoguchi K (1994) Pervaporation of ethanol/water through a poly(vinyl alcohol)/cyclodextrin (PVA/CD) membrane. J Membr Sci 89:111–117

Rachipudi PS, Kariduraganavar MY, Kittur AA, Sajjan AM (2011) Synthesis and characterization of sulfonated-poly(vinyl alcohol) membranes for pervaporation dehydration of isopropanol. J Membr Sci 383:224–234

Huang RYM, Yeom CK (1991) Pervaporation separation of aqueous mixtures using crosslinked polyvinyl alcohol membranes. III. Permeation of acetic acid–water mixtures. J Membr Sci 58:33–47

Weinkauf DH, Paul DR (1990) Effects of structural order on barrier properties. In: Koros WJ (eds) Barrier polymers and structures. ACS Symp Ser Washington, Washington, DC, vol 423, pp 61–91

Acknowledgements

We gratefully acknowledge the UGC, New Delhi (F. No. 37-245/3009, SR) for providing financial support. Authors sincerely thank the Department of Physics, Indian Institute of Science, Bangalore, for extending wide-angle X-ray diffraction facility.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sajjan, A.M., Premakshi, H.G. & Kariduraganavar, M.Y. Synthesis and characterization of polyelectrolyte complex membranes for the pervaporation separation of water–isopropanol mixtures using sodium alginate and gelatin. Polym. Bull. 75, 851–875 (2018). https://doi.org/10.1007/s00289-017-2062-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2062-7