Abstract

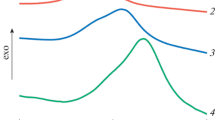

Inorganic particles have been common fillers for processing butyl rubber (IIR). Studying the effect of inorganic particles on the molecular motions of IIR was important to both relevant theory and applications. In this paper, the morphology and dynamics of IIR/silica, IIR/carbon black and IIR/Fe3O4 blends were studied. It was found that silica was homogenously dispersed in IIR and it suppressed the molecular motions of IIR at all loads. In addition, the carbon black with a low load averagely dispersed in IIR and suppressed the molecular motions of IIR; however, it agglomerated and the suppression was weakened as the load was increased. Moreover, Fe3O4 had nearly no influence on the molecular motions of IIR.

Similar content being viewed by others

References

Anderson PW (1995) Through the glass lightly. Science 67:1616. doi:10.1126/science.267.5204.1615

Wu JR, Huang GS, Wang XA, He XJ, Zheng J (2011) Detecting different modes of molecular motion in polyisobutylene and chlorinated butyl rubber by using dielectric probes. Soft Matter 7:9224–9230. doi:10.1039/c1sm05748k

Wu XB, Wang HG, Liu CS, Zhu ZG (2011) Longer-scale segmental dynamics of amorphous poly(ethylene oxide)/poly(vinyl acetate) blends in the softening dispersion. Soft Matter 7:579–586. doi:10.1039/c0sm00633e

Sahoo KL, Sahu R (2013) Glass transition and crystallization of Al-Ni-La based metallic glasses studied by temperature modulated DSC. J. Non Cryst Solids 365:33–36. doi:10.1016/j.jnoncrysol.2013.01.031

Wu JR, Huang GS, Wang XA, He XJ, Lei HX (2011) Molecular dynamics in chlorinated butyl rubber containing organophilic montmorillonite nanoparticles. J Polym Res 18:2213–2220. doi:10.1007/s10965-011-9632-4

Ngai KL (2012) Universal relaxation and diffusion in many-body interacting systems: an outstanding unsolved problem. Physics 41:285–296

Wu JR, Huang GS, Wang XA, He XJ, Lei HX (2010) Confinement effect of polystyrene on the relaxation behavior of polyisobutylene. J Polym Sci, Part B: Polym Phys 48:2165–2172. doi:10.1002/polb.22098

Plazek DJ, Zheng XD, Ngai KL (1992) Viscoelastic properties of amorphous polymers. 1. Different temperature dependences of segmental relaxation and terminal dispersion. Macromolecules 25:4920–4924. doi:10.1021/ma00045a016

Zhang R, He XR, Huang GS (2015) A review of the slow relaxation processes in the glass–rubber transition region of amorphous polymers. Phase Trans 88:843–858. doi:10.1080/01411594.2015.1007373

Ngai KL, Capaccioli S, unified explanation of the anomalous dynamic properties of highly asymmetric polymer blends J Chem Phys 138: 054903. doi: 10.1063/1.4789585

Zhang FS, He GS, Xu KM, Wu H, Guo SY (2014) Damping mechanism and different modes of molecular motion through the glass transition of chlorinated butyl rubber and petroleum resin blends. J Appl Polym Sci 131:40640. doi:10.1002/app.40464

Zhang R, He XR (2015) Crystallization and molecular dynamics of ethylene-vinyl acetate copolymer/butyl rubber blends. RSC Adv 5:130–135. doi:10.1039/c4ra10568k

He XR, Huang GS, Zhou H, Jiang LX, Zhao XD (2005) Investigation on the damping behavior of CIIR/PMAc blends. Acta Polym Sinca 1:108–112

Zhang R, He XR, Huang GS (2014) Dynamics of poly (butyl acrylate) and poly (ethyl acrylate) with internal double bonds. J Polym Res. doi:10.1007/s10965-014-0388-5

Zhang R, He XR, Yu H (2014) Why tanδ of poly (butyl acrylate) and poly (ethyl acrylate) with little double bonds are becoming asymmetric? Polymer 55:4720–4727. doi:10.1016/j.polymer.2014.07.016

He XR, Yu H, Zhang R, Yang CH (2014) Enhance slower relaxation process of poly(ethyl acrylate) through internal plasticization. Int Polym Proc 29:419–424. doi:10.3139/217.2882

Liao FS, Su AC, Hsu TJ (1994) Damping behaviour of dynamically cured butyl rubber/polypropylene blends. Polymer 35:2579–2586. doi:10.1016/0032-3861(94)90382-4

Wu GZ, Asai S, Sumita M, Yui H (2002) Entropy penalty-induced self-assembly in carbon black or carbon fiber filled polymer blends. Macromolecules 35:945–951. doi:10.1021/ma0104940

Li QY, Wu GZ, Zhang XL, Wu CF (2006) Preparation of poly (n-butyl acrylates) encapsulated carbon black via ultrasonic irradiation initiating emulsion polymerization. Polym J 38:1245–1250. doi:10.1295/polymj.PJ2006053

Di X, Win KZ, McKenna GB, Narita T, Lequeux F, Pullela SR, Cheng Z (2011) Signatures of structure recovery in colloidal glasses. Phys Rev Lett 106:095701. doi:10.1103/PhysRevLett.106.095701

Di X, Peng XG, McKenna GB (2014) Dynamics of a thermo-responsive microgel colloid near to the glass transition. J Chem Phys 140:054903. doi:10.1063/1.4863327

Wu GZ, Asai S, Sumita M (2002) Carbon black as a self-diagnosing probe to trace polymer dynamics in highly filled compositions. Macromolecules 35:1708–1713. doi:10.1021/ma011658f

He XR, Yu H, Wang X, Huang GS, Zhang R (2013) The influence of vulcanization agents on vulcanization kinetics of chloride butyl rubber. Int Polym Proc 28:398–414. doi:10.3139/217.2770

He XR, Yu H, Rong YQ, Zhang R, Huang GS (2014) A study of non-isothermal kinetic reaction for vulcanization of chloride butyl rubber via phenol formaldehyde resin. Int Polym Proc 29:342–349. doi:10.3139/217.2722

Zhang R, He XR, Yang DB, Lai ZP (2015) Non-isothermal crystallization kinetics and segmental dynamics of high density polyethylene/butyl rubber blends. Polym Int 64:1252–1261. doi:10.1002/pi.4910

Acknowledgments

This work was supported by the department of science of Sichuan province (2015JY0052) and the open fund (X151514KCL22) from Sichuan Province Key Laboratory of Materials for Oil and Gas Industry.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, R., He, X., Lai, Z. et al. Effect of some inorganic particles on the softening dispersion of the dynamics of butyl rubber. Polym. Bull. 74, 1031–1043 (2017). https://doi.org/10.1007/s00289-016-1761-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-016-1761-9