Abstract

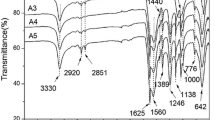

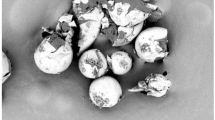

Paraffin oil was encapsulated in a urea–formaldehyde polymer shell by in situ polymerization. The effect of modifying the fabrication parameters, specifically the emulsifier, the core material concentration, the stirring rate, and the pH, on the resulting microcapsules was characterized by FTIR, SEM, particle size analysis and TGA. The stiffness and the mechanical stability during mixing of the microcapsules were also evaluated. It was found that the ethylene maleic anhydride copolymer (EMA)-based microcapsules are smaller, harder and have an increase in yield of 15 % or more compared to the polyvinyl alcohol (PVA)-based microcapsules. Both EMA- and PVA-based microcapsules have good thermal stability up to 400 °C. Smaller EMA-based microcapsules require a higher force, up to 0.96 N, to be 80 % deformed.

Similar content being viewed by others

References

Biju SS, Saisivam S, Maria NS, Rajan G, Mishra PR (2004) Dual coated erodible microcapsules for modified release of diclofenac sodium. Eur J Pharm Biopharm 58:61–67

Yutaka U, Kenichi H, Kageyosi S, Kazunori A, Yoshikazu T, Mutsuo S (2001) Improved survival and ammonia metabolism by intraperitoneal transplantation of microencapsulated hepatocytes in totally hepatectomized rats. Surgery 130:513–520

Yufera M, Fernandez-Diaz C, Pascual E (2005) Food microparticles for larval fish prepared by internal gelation. Aquaculture 248:253–262

Giraud S, Bourbigot S, Rochery M, Vroman I, Tighzert L, Delobel R (2002) Microencapsulation of phosphate: application to flame retarded coated cotton. Polym Degrad Stab 77:285–297

Krishnan S, Bhosale R, Singhal RS (2005) Microencapsulation of cardamom oleoresin: evaluation of blends of gum arabic, maltodextrin and a modified starch as wall materials. Carbohydr Polym 61:95–102

Kim CA, Joung MJ, Ahn SD, Kim GH, Kang SY, You IK, Oh J, Myoung HJ, Baek KH, Suh KS (2005) Microcapsules as an electronic ink to fabricate color electrophoretic displays. Synth Met 151:181–185

Guo HL, Zhao XP (2004) Preparation of a kind of red encapsulated electrophoretic ink. Opt Mater 26:297–300

Nelson G (2002) Application of microencapsulation in textiles. Int J Pharm 242:55–62

Sukhorukov G, Fery A, Mohwald H (2005) Intelligent micro- and nanocapsules. Prog Polym Sci 30:885–897

Palanikkumaran M, Gupta KK, Agrawal AK, Jassal M (2010) Effect of emulsion preparation method on microencapsulation of n-octadecane using melamine-formaldehyde pre-polymers. Ind J Fibre Text Res 35:101–106

Farid MM, Khudhair AM, Amar M, Razack SKA, Al-Hallaj S (2004) A review on phase change energy storage: materials and application. Energy Convers Manag 45:1597–1615

Shin Y, Yoo D, Son K (2005) Development of thermoregulating textile materials with microencapsulated phase change materials (PCM) II: preparation and application of PCM microcapsules. J Appl Polym Sci 96:2005–2010

Choi J, Lee JG, Kim HO, Yang H (2001) Preparation of microcapsules containing phase change materials as heat transfer media by in situ polymerization. J Ind Eng Chem 7:358–362

Hawlader MNA, Uddin MS, Khin MM (2003) Microencapsulation phase change materials: thermal-energy storage system. Appl Energy 74:195–202

Hohnston JH, Dodds M (2011) The development of a flexible re-useable thermal buffering and insulating liner for packing temperature sensitive products. Appita 64:153–157

Hoshi Y, Hayashy T (1983) US Patent 4409156 (to Fuji Photo Film Co., Ltd., Kanagawa, Japan)

Thies C (1987) Microencapsulation: polymer science and engineering encyclopedia. Willey, New York

Zhang Z, Sun G (2002) Mechanical strength of microcapsules made of different wall materials. Int J Pharm 242:307–311

Fallahi E, Barmar M, Kish MH (2010) Preparation of phase-change material microcapsules with paraffin or camel fat cores: application to fabrics. Iran Polym J 19:277–286

Mayya KS, Bhattacharra A, Argillier JF (2003) Microencapsulation by complex coacervation: influence of surfactant. Polym Int 52:644–647

Bhattacharra A, Argillier JF (2005) Microencapsulation by complex coacervation: effect of cationic surfactant. J Surf Sci Technol 21:161–168

Mao J, Yang H, Zhou X (2012) In-situ polymerization of uniform poly(urea–formaldehyde) microcapsules containing paraffins under the high-speed agitation without emulsifier. Polym Bull 69:649–660

Brown EN, Kessler MR, Sottos NR, White SR (2003) In situ poly(urea–formaldehyde) microencapsulation of dicyclopentadiene. J Microencapsul 20:719–730

Park SJ, Shin YS, Lee JR (2001) Preparation and characterization of microspheres containing lemon oil. J Colloid Interface Sci 241:502–508

Suryanarayana C, Rao KC, Kumar D (2008) Preparation and characterization of microcapsules containing linseed oil and its use in self-healing coatings. Prog Org Coat 63:72–78

Spectral Database for Organic Compounds (SDBS), organized by National Institute of Advanced Industrial Science and Technology (AIST), Japan (2014). http://riodb01.ibase.aist.go.jp/sdbs/cgi-bin/direct_frame_top.cgi

Mehdiabadi S, Nehzat MS, Bagheri R (1998) Correlating viscosity in urea–formaldehyde polymerization. J Appl Polym Sci 69:631–636

Jadhav RS, Hundiwale DG, Mahulikar PP (2011) Synthesis and characterization of phenol–formaldehyde microcapsules containing linseed oil and its use in epoxy for self-healing and anticorrosive coating. J Appl Poly Sci 119:2911–2916

Zhang XX, Tao XM, Yick KL, Wang XC (2004) Structure and thermal stability of microencapsulated phase-change materials. Colloid Polym Sci 282:330–336

Boh B, Knez E, Staresinic M (2005) Microencapsulation of higher hydrocarbon phase change materials by in situ polymerization. J Microencapsul 22:715–735

Hu J, Chen H, Zhang Z (2009) Mechanical properties of melamine formaldehyde microcapsules for self-healing materials. Mater Chem Phys 118:63–70

Chao HY (1992) Polyurea and polyurea-epoxy microcapsules, Google Patents (Patent #CA1300987C)

Acknowledgments

This publication was made possible by NPRP Grant 4-800-2-297 from the Qatar National Research Fund (a member of Qatar Foundation). The statements made herein are solely the responsibility of the authors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fayyad, E.M., Almaadeed, M.A. & Jones, A. Preparation and characterization of urea–formaldehyde microcapsules filled with paraffin oil. Polym. Bull. 73, 631–646 (2016). https://doi.org/10.1007/s00289-015-1518-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-015-1518-x