Abstract

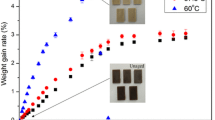

Chemically treated jute fabric (TJF)- and untreated jute fabric (UJF)-reinforced isotactic polypropylene (PP)-sandwiched composites, such as TJF composite (TC) and UJF composite (UC), with different JF contents (35–60 wt%) were fabricated by the compression molding technique. Then, PP, UC and TC were irradiated by γ–rays with various doses (0–7.5 kGy) to produce γPP, γUC and γTC, respectively. Water intake (WI), chemical texture, tensile strength (TS), flexural strength (FS), Young’s modulus (Y) and thermal degradation temperatures (T d) of the samples were examined. Activation energy (E a) during thermal degradation has been estimated by Broido’s theory. WI in TC, γUC and γTC is lower than that in UC, as accompanied by the change in interfacial textures between JF and PP. The TS, FS, Y, T d and E a values of UC, TC, γUC and γTC are found to lie in the ranges 52–61, 55–63, 440–710 MPa, 400–440 °C and 280–340 kJ/mol, respectively. A relative estimation of physical and chemical crosslinking densities/junctions in the composites has been performed and the values have been analyzed by the rubber elasticity and polymer gel theories. The observed changes in physico-mechanical and thermal properties of the composites have been explained on the basis of crosslinking/bonding between JF and PP. Fourier transform infrared spectroscopy confirms the fiber–matrix interactions. A significant increase in Y and T d values demonstrates a development of strong and thermally more stable JF-reinforced PP composites in the present study.

Similar content being viewed by others

References

Feldman D, Barbalata A (1996) Synthetic polymers: technology, properties and applications. Chapman and Hall, London

Campbell IM (2000) Introduction to synthetic polymers. Oxford University Press, Oxford

Mohanty AK, Misra M, Hinrichsen G (2000) Biofibers biodegradable polymers and biocomposite—an overview. Macromol Mater Eng 276(277):1–24

Mohanty AK, Misra M, Drzal LT (2005) Natural fibers, biopolymers and biocomposites. Tailor and Francis, CRC Press, Singapore

Kabir MA, Haque MM, Islam MR, Bledzki AK (2010) Mechanical properties of Jute fiber reinforced polypropylene composite: effect of chemical modification by benzene diazonium salt in alkaline medium. Bio Resource 5:1618–1625

Rahman MR, Hasan M, Haque MM, Islam MN (2010) Physico-mechanical properties of jute fiber reinforced polypropylene composites. J Rein Plast Compos 29:445–455

Mohanty AK, Khan MA, Hinrichen G (2000) Surface modification of jute and its influence on performance of biodegradable jute fabric/biopole composites. Compos Sci Technol 60:1115–1124

Pervaiz M, Sain MM (2003) Sheet molded polyolefin natural fiber composites for automotive applications. Macromol Mater Eng 288:553–557

Khan MA, Hossain M, Ali KI (1999) Jute composite with MMA by gamma and UV radiations in the presence of additives. J Appl Polym Sci 74:900–906

Khan MA, Hassan MM, Drzal LT (2005) Effect of 2-hydroxyethyl methacrylate (HEMA) on the mechanical and thermal properties of jute/polycarbonate composites. Composites Part A Appl Sci Manuf 36:71–81

Santos EF (2009) Effectiveness of maleated- and silanized-PP for coir fiber-filled composites. J Rein Plast Compos 28:2119–2129

Rana AK, Mandal A, Mitra BC, Jacobson R, Rowell R, Banerjee AN (1997) Short jute fiber-reinforced polypropylene composites: effect of compatibilizer. J Appl Polym Sci 69:329–338

Arondo LM, Perez CJ, Carella JM (2005) Injection molding of long sisal fiber-reinforced polypropylene: effects of compatibilizer concentration and viscosity on fiber adhesion and thermal degradation. Polym Eng Sci 45:613–621

Sombatsompop N, Yotinwattanakumtorn C, Thongpin C (2005) Influence of type and concentration of maleic anhydride grafted polypropylene and impact modifiers on mechanical properties of PP/wood sawdust composites. J Appl Polym Sci 97:475–484

Mohanty AK, Patnaik S, Singh BC, Misra M (1989) Graft copolymerization of acrylonitrile onto acetylated jute fibers. J Appl Polym Sci 37:1171–1181

Ray D, Sarkar BK, Bose NR (2002) Impact fatigue behaviors of vinyl ester resin matrix composites reinforced with alkali treated jute fibers. Compos Part A Appl Sci Manuf 23:233–241

Ray D, Sarkar BK, Das S, Rana AK (2002) Dynamic mechanical and thermal analysis of vinyl ester resin matrix composites reinforced with untreated and alkali treated jute fibers. Compos Sci Tech 62:911–917

Broido A (1969) A simple, sensitive graphical method of treating thermogravimetric analysis data. J Polym Sci Part A-2 7:1761–1773

Saha P, Manna S, Chowdhury SR, Sen R, Roy D, Adhikari B (2010) Enhancement of tensile strength of lignocellulosic jute fibers by alkali-steam treatment. Bioresour Technol 101:3182–3187

Snyder RG, Schachtschneider JH (1964) Valence force calculation of the vibrational spectra of crystalline isotactic polypropylene and some deuterated polypropylenes. Spectrochim Acta 20:853–869

Park DK, Park JW, Kim I, Ha CS (2005) Preparation and characterization of metallocene-catalyzed isotactic polypropylene and/or syndiotactic polypropylene single crystals; preliminary studies. J Adhes Interface (Korea) 6:1–5

Roy A, Chakrabarti S, Kundu SP, Basak RK, Majumder SB, Adhikari B (2012) Improvement in mechanical properties of jute fibers through mild alkali treatment as demonstrated by utilization of the Weibull distribution model. Bioresorc Technol 107:222–228

Öztürk I, Irmak S, Hesennov A, Erabatur O (2010) Hydrolysis of kenaf (Hibiscus cannabinus L.) stems by catalytic thermal treatment in subcritical water. Biomass Bioenergy 34:1578–1585

Haydaruzzaman, Khan RA, Mubarak AK, Khan AH, Hossain MA (2009) Effect of gamma radiation on the performance of jute fabrics-reinforced polypropylene composites. Radiat Phys Chem 78:986–993

Joseph PV, Joseph K, Thomas Pillai CKS, Prasad VS, Groeninckx G, Sarkissova M (2003) The thermal and crystallisation studies of short sisal fibre reinforced polypropylene composites. Compos Part A Appl Sci Manuf 34:253–266

Mohanty S, Nayak SKJ (2006) Interfacial, dynamic mechanical, and thermal fiber reinforced behavior of MAPE treated sisal fiber reinforced HDPE composites. Appl Polym Sci 102:3306–3315

Kumer RV, Koltypin Y, Gedanken AJ (2002) Preparation and characterization of nickel–polystyrene nanocomposite by ultrasound irradiation. Appl Polym Sci 86:160–165

Tripathi D, Dey TK (2013) Thermal conductivity, coefficient of linear thermal expansion and mechanical properties of LDPE/Ni composites. Indian J Phys 87:435–445

Fuad MY, Mustafah J, Mandor MS, Mohd Ishak ZA, Mohd Omar AK (1995) Thermal properties of polypropylene/rice husk ash composites. Polym Intl 38:33–43

Gann RG, Dipert A, Drews MJ (1987) Flammability. In: Kroschwitz JI (ed), Encycl Polym Sci Eng, Vol. 7, 2nd edn. Wiley, New York, pp 154–210

Abdel-Aal N, El-Tantawy F, Al-Hajry A, Bououdina M (2008) Epoxy resin/plasticized carbon black composites. Part II. Correlation among network structure and mechanical properties. Polym Compos 29:804–808

Doi M, Edwards SF (1986) The theory of polymer dynamics. Oxford University Press, Oxford

Acknowledgments

The authors greatly acknowledge the Bangladesh University of Engineering and Technology (BUET) to provide financial support for this investigation. They are grateful to the Atomic Energy Research Establishment (AERE), and Bangladesh Council of Scientific and Industrial Research (BCSIR) to allow facilities for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shohrawardy, M.H.S., Alam, M.K., Mina, M.F. et al. Fabrication of strong and thermally more stable jute fabric/polypropylene composites by compression molding along with γ-ray irradiation. Polym. Bull. 71, 1219–1239 (2014). https://doi.org/10.1007/s00289-014-1120-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-014-1120-7