Abstract

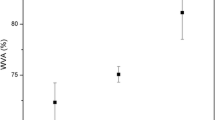

Blends of recycled polypropylene (PP) and starch (S) with the compositions polypropylene 83 wt%–starch 17 wt% (PP83/S17) (blend 1a), polypropylene 68.8 wt%–starch 31.2 wt% (PP 68.8/S 31.2) (blend 2a) and polypropylene 89.5 wt%–starch 10.5 wt% (PP 89.5/S 10.5) (blend 3a) were synthesized. Maleated polypropylene (MAPP) was used as a compatibilizer. The compositions of the compatibilized blends were PP73/S15/MAPP12 (blend 1b), PP55/S25/MAPP20 (blend 2b) and PP85/S10/MAPP5 (blend 3b). The occurrence of a reaction between MAPP and starch was studied using Fourier transform infrared analysis. Thermal and rheological properties such as the complex viscosity, storage and loss modulus of the blends with a compatibilizer were found to be higher than those of the blends without a compatibilizer. The compatibilized and uncompatibilized blends, as well as recycled PP, were characterized using differential scanning calorimetry, thermogravimetric analysis and cone-and-plate rheometry. The storage and loss modulus values of blend 3b were observed to be the best. The best compatibilizing effect was exhibited by blend 3b at a loading of 5 wt% MAPP because this compatibilizer content yielded the highest complex viscosity and visco-elastic behavior. The presence of a functional compatibilizer enhanced the interactions between starch and recycled PP, which was confirmed by a rise in the melt viscosity, storage modulus and thermal stability. These blends were also characterized in terms of their water uptake by performing water absorption tests. Blend 2b containing 20 % MAPP was observed to absorb the maximum amount of water at 25 °C.

Similar content being viewed by others

References

Deepika Khanna N, Inderjeet K, Anil K (2011) Starch-grafted polypropylene: synthesis and characterization. J Appl Polym Sci 119:602–612

Michel AH, Hongbo L (2012) Preparation and properties of extruded thermoplastic starch/polymer blends. J Appl Polym Sci 126:E96–E108

Aichholzer W, Fritz HG (1998) Rheological characterization of thermoplastic starch materials. Starch/Stärke 50:77–83

Vergnes B, Villemaire JP (1987) Rheological behaviour of low moisture molten maize starch. Rheol Act 26:570–576

Villar MA, Thomas EL, Armstrong RC (1995) Rheological properties of thermoplastic starch and starch/poly(ethylene-co-vinyl alcohol) blends. Polym 36:1869–1876

Willett JL, Jasberg BK, Swanson CL (1995) Rheology of thermoplastic starch: effects of temperature, moisture content, and additives on melt viscosity. Polym Eng Sci 35:202–210

VanSoest JJG, Hulleman SHD, deWit D, Vliegenthart JFG (1996) Crystallinity in starch bioplastics. Ind Crops Prod 5:11–22

VanSoest JJG, Knooren N (1997) Influence of glycerol and water content on the structure and properties of extruded starch plastic sheets during aging. J Appl Polym Sci 64:1411–1422

Schwach E, Averous L (2004) Starch-based biodegradable blends: morphology and interface properties. Polym Int 53:2115–2124

Simmons S, Thomas EL (1995) Structural characteristics of biodegradable thermoplastic starch/poly(ethylene–vinyl alcohol) blends. J Appl Polym Sci 58:2259–2285

Bikiaris D, Panayiotou C (1998) LDPE/starch blends compatibilized with PE-g-MA copolymers. J Appl Polym Sci 70:15031521

Averous L, Moro L, Dole P, Fringant C (2000) Properties of thermoplastic blends: starch–polycaprolactone. Polym 41:4157–4167

Raquez JM, Nabar Y, Narayan R, Dubois P (2008) In situ compatibilization of maleated thermoplastic starch/polyester melt-blends by reactive extrusion. Polym Eng Sci 48:1747–1754

Seethamrajul K, Battacharya M, Vaidya UR, Fulcher RG (1994) Rheology and morphology of starch/synthetic polymer blends. Rheol Act 33:553–567

Heikens D, Hoen N, Barentsen W, Piet P, Landan H (1978) Mechanical properties and morphology of copolymer modified polymer blends. J Polym Sci Polym Symp 62:309–341

Schreiberv HP, Olguin A (1983) Aspects of dispersion and flow in thermoplastic-elastomer blends. Polym Eng Sci 23:129–134

Oene HV (1978) Rheology of polymer blends and dispersion. In: Paul DR, Newman S (eds) Polymer blends, vol 1. Academic Press, New York, p 295

Utracki LA (1988) The rheology of two phase flows. In: Collyer AA, Clegg DW (eds) Rheological measurements. Elsevier Applied Science, New York, p 479

Karnis A, Goldsmith HL, Mason SG (1966) The kinetics of flowing dispersions: I. Concentrated suspensions of rigid particles. J Colloid Inter Sci 22:531–553

Onogi S, Matsumoto T (1981) Rheological properties of polymer solutions and melts containing suspended particles. Polym Eng Rev 1:45–87

Kreiger IM, Choi GN (1984) Rheology of sterically stabilized dispersions. In: Mena B, Garcia-Rejon A, Rangel-Nafaile C (eds) Proceedings IX International Congress of Rheology Advances in Rheology. University Nature Autonomy Mexico, 2:641

Chaleat CM, Halley PJ, Truss RW (2008) Properties of a plasticised starch blend. Part 1: influence of moisture content on fracture properties. Carb Polym 71:535–543

Candice DL, Caio AP, Maria DCG, Sachin V (2011) Preparation and characterization of clay nanocomposites of plasticized starch and polypropylene polymer blends. J polym Env 19:689–697

Al-Mulla A, Mathew J, Al-Omairi L, Battacharya S (2011) Thermal decomposition kinetics of tricomponent polyester/polycarbonate systems. Polym Eng Sci 51:2335–2344

ASTM D570–98 (2010) Standard test method for water absorption of plastics

John Z, Ioan IN, Qinglin Wu (2005) Maleated wood-fiber/high-density-polyethylene composites: coupling mechanisms and interfacial characterization. Compos Interfaces 12:125–140

Dangseeyun N, Supaphol P, Nithitanakul M (2004) Thermal, crystallization, and rheological characteristics of poly(trimethylene terephthalate)/poly(butylene terephthalate) blends. Polym Test 23:187–194

Onogi S, Asada T (1980) Rheology. In: Astarita G, Marrucci G, Nicolais G (eds) Principles, vol 1. Plenum Press, New York, pp 127

Bruyn HD, Sprong E, Gaborieau M, David G, Roper JA, Gilbert RG (2006) Starch-graft-copolymer latexes initiated and stabilized by ozonolyzed amylopectin. J Polym Sci Part A Polym Chem 44:5832–5845

Acknowledgments

The authors would like to thank the research administration of Kuwait University for providing funds from the project EC 01/11 to carry out this research work. The authors are also grateful to the research department of Kuwait University for allowing rheological analyses to be conducted at the Kuwait University Nanotechnology Research Facility GE 01/07 (KUNRF). The authors are also grateful to the research department of Kuwait University for allowing us to carry out FTIR analysis at the Kuwait University Petroleum Refining and Petrochemical Research (PRP) Center GE (03/08).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Mulla, A., Alfadhel, K., Qambar, G. et al. Rheological study of recycled polypropylene–starch blends. Polym. Bull. 70, 2599–2618 (2013). https://doi.org/10.1007/s00289-013-0977-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-013-0977-1