Abstract

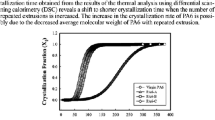

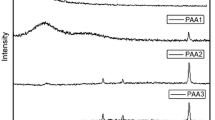

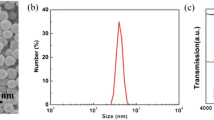

Shear and extensional rheometry was carried out on polyamide 6 (PA6) reinforced with crosslinked polyacrylic nanoparticles (PNPs) with mean size of 8 nm. The PNPs were dispersed into a commercial, injection grade, PA6 matrix by melt extrusion, at a concentration of 3 wt%. Thermal analysis showed that the PNPs did not influence the melting and decomposition temperature of the polymer matrix. However, grafting of maleic anhydride to the PNPs (denoted PNP-g-MA) increased the decomposition temperature. On the other hand, X-ray scattering and small-angle light scattering showed that the degree of crystallinity and crystal size were reduced, relative to the neat PA6, i.e., the PNPs disrupted the ordering of the polymer chains. The shear rheological properties showed that the PA6/PNP nanocomposites exhibited a linear viscoelastic behavior. Small-strain oscillatory shear showed that PA6 exhibited a predominantly viscous behavior. However, addition of PNPs induced a predominantly elastic behavior, as measured by the mechanical damping tan δ (=G″/G′), and increased the zero-shear viscosity. The increase in melt elasticity and viscosity was greater for the PA6/PNP-g-MA nanocomposite. Extensional rheometry experiments demonstrated that when PNPs were added to PA6, they induced smaller extensional viscosity, η ext, values in the matrix, at low strain rates. However, at higher strain rates the PNPs induced a strain hardening behavior. Whereas the neat polymer melt rapidly broke under extensional flow, the PA6/PNP nanocomposites first exhibited lower η ext than the neat PA6, and then η ext rapidly increased before breaking, i.e. a strain hardening behavior. The higher melt elasticity of the molten PA6 nanocomposites appears to arise from a jamming effect promoted by the PNPs.

Similar content being viewed by others

References

Kojima Y, Usuki A, Kawasumi M, Okada A, Kurauchi T, Kamigaito O (1993) Synthesis of nylon 6-clay hybrid by montmorillonite intercalated with ε-caprolactam. J Polym Sci Part A Polym Chem 31:983–986

Biswas M, Sinha S (2001) Recent progress in synthesis and evaluation of polymer-montmorillonite nanocomposites. Adv Polym Sci 155:167–221

Vaia RA, Ishii H, Giannelis EP (1993) Synthesis and properties of two-dimensional nanostructures by direct intercalation of polymer melts in layered silicates. Chem Mater 5:1694–1696

Giannelis EP (1996) Polymer layered silicate nanocomposites. Adv Mater 8:29–35

Gao F (2004) Clay/Polymer composites: the story. Mater Today 7:50–55

Nguyen QT, Baird DG (2006) Preparation of polymer/clay nanocomposites and their properties. Adv Polym Technol 25:270–285

Lee JY, Shim MJ, Kim SW (1999) Effect of natural zeolite on the mechanical properties of epoxy matrix. Polym Eng Sci 39:1993–1997

Singhal R, Datta M (2007) Development of nanocomposites of bentonite with polyaniline and poly(methacrylic acid). J Appl Polym Sci 103:3299–3306

Santiago F, Mucientes AE, Osorio M, Rivera C (2007) Preparation of composites and nanocomposites based on bentonite and poly(sodium acrylate). Effect of amount of bentonite on the swelling behaviour. Euro Polym J 43:1–9

Romero-Guzman ME, Romo-Uribe A, Ovalle-Garcia E, Olayo R, Cruz-Ramos CA (2008) Microstructure and dynamic mechanical analysis of extruded layered silicate PVC nanocomposites. Polym Adv Techn 19:1168–1176

Shao W, Wang Q, Wang F, Chen Y (2006) Polyamide-6/natural clay mineral nanocomposites prepared by solid-state shear milling using Pan-Mill equipment. J Poly Sci Poly Phys 44:249–255

Pucciariello R, Villani V, Guadagno L, Vittoria V (2006) Equilibrium thermal behavior and morphology of organophilic montmorillonite/poly(e-caprolactone) nanocomposites. J Poly Sci Poly Phys 44:22–32

Yalcin B, Ergungor Z, Konishi Y, Cakmak M, Batur C (2008) Molecular origins of toughening mechanism in uniaxially stretched nylon 6 films with clay nanoparticles. Polymer 49:1635–1650

Valentini L, Biagiotti J, López-Manchado MA, Santucci S, Kenny JM (2004) Effects of carbon nanotubes on the crystallization behavior of polypropylene. Polym Eng Sci 44:303–311

Mitchell CA, Bahr JL, Arepalli S, Tour James M, Krishnamoorti R (2002) Dispersion of functionalized carbon nanotubes in polystyrene. Macromolecules 35:8825–8830

Romo-Uribe A, Mather PT, Haddad TS, Lichtenhan JD (1998) Viscoelastic and morphological behavior of hybrid styryl-based polyhedral oligomeric silsesquioxane (POSS) copolymers. J Polym Sci Polym Phys 36:1857–1872

Mather PT, Jeon HG, Romo-Uribe A, Haddad TS, Lichtenhan JD (1999) Mechanical relaxation and microstructure of poly(norbornyl-POSS) copolymers. Macromolecules 32:1194–1203

Kopesky ET, Haddad TS, McKinley GH, Cohen RE (2005) Miscibility and viscoelastic properties of acrylic polyhedral oligomeric silsesquioxane-poly(methyl methacrylate) blends. Polymer 46:4743–4752

Wu J, Haddad TS, Kim GM, Mather PT (2007) Rheological behavior of entangled polystyrene-polyhedral oligosilsesquioxane (POSS) copolymers. Macromolecules 40:544–554

Lichtenhan JD, Vu NQ, Carter JA (1993) Silsesquioxane-siloxane copolymers from polyhedral silsesquioxanes. Macromolecules 26:2141–2142

Lichtenhan JD, Otonari YA, Carr MJ (1995) Linear hybrid polymer building blocks: methacrylate-functionalized polyhedral oligomeric silsesquioxane monomers and polymers. Macromolecules 28:835–8437

Haddad TS, Lichtenhan JD (1995) The incorporation of transition metals into polyhedral oligosilsesquioxane polymers. J Inorg Organomet Polym 5:237–246

Haddad TS, Lichtenhan JD (1996) Hybrid organic-inorganic thermoplastics: styryl-based polyhedral oligomeric silsesquioxane polymers. Macromolecules 29:7302–7304

Sumita M, Shizuma T, Miyasaka K, Ishikawa K (1983) Effect of reducible properties of temperature, rate of strain, and filler content on the tensile yield stress of nylon 6 composites filled with ultrafine particles. J Macromol Sci Phys B22:601–618

Flores O, Romo-Uribe A, Romero-Guzman ME, Gonzalez AE, Cruz-Silva R, Campillo B (2009) Mechanical properties and fracture behavior of polypropylene reinforced with polyaniline-grafted-short glass fibers. J Appl Polym Sci 112:934–941

Lee KM, Knight PT, Chung T, Mather PT (2008) Polycaprolactone-POSS Chemical/Physical Double Networks. Macromolecules 41:4730–4738

Romero-Guzmán ME, Romo-Uribe A, Zárate-Hernández BM, Cruz-Silva R (2009) Viscoelastic properties of POSS-styrene nanocomposite blended with polystyrene. Rheo Acta 48:641–652

Romo-Uribe A, Alvarado-Tenorio B, Romero-Guzmán ME (2010) A small-angle light scattering instrument to study soft condensed matter. Rev Latin Am Metal Mat 30:190–200

Huitrón-Rattinger E, Alvarado-Tenorio B, Romo-Uribe A (2011) Nylon 6 reinforced with acrylic polymer nanoparticles. Thermal properties and nano structure. Mater Res Soc Symp Proc 1312:201–206

Pashaei S, Siddaramaiah Avval MM, Syed AA (2011) Thermal degradation kinetics of nylon 6/GF/crysnano nanoclay nanocomposites by TGA. Chem Ind Chem Eng Quart 17:141–151

Meister JJ Ed. (2000) Polymer Modification: Principles, Techniques and Applications. Marcel Dekker, New York. p 444

Gonzalez-Montiel A, Keskkula H, Paul DR (1995) Morphology of nylon6/polypropylene blends compatibilized with maleated polypropylene. J Polym Sci Polym Phys 33:1751–1767

Robeson LM (2007) Polymer blends. a comprehensive review. Carl Hanser Verlag, Munich, p 74

Wunderlich B (1990) Thermal analysis. Academic Press, New York

Holmes DR, Bunn CW, Smith DJ (1955) The crystal structure of polycaproamide: nylon 6. J Polym Sci 17:159

Alexander L (1969) X-ray diffraction methods in polymer science. Wiley, London

Stein RS (1964) Newer methods of polymer characterization. Interscience Publishers, New York, p 155

Larson RG (1999) The structure and rheology of complex fluids. Oxford University Press, Oxford

Zhang Q, Archer LA (2002) Poly(ethylene oxide)/silica nanoparticles: structure and rheology. Langmuir 18:10435–10442

Mackey M, Dao TT, Tuteja A, Ho DL, Van Horn B, Kim HC, Hawker CJ (2003) Nanoscale effects leading to non-Einstein-like decrease in viscosity. Nat Mater 2:762–766

Acknowledgments

E Huitrón-Rattinger was supported by a graduate scholarship from the Mexican Council for Science and Technology (CONACyT). Thanks to TA Instruments for enabling access to the Extensional Viscosity Fixture (EVF). This research was supported by CONACyT (Ciencia Basica 2011 program, grant 168095).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huitrón-Rattinger, E., Romo-Uribe, A. Shear and extensional rheometry of PA6 reinforced with polyacrylic nanoparticles. Polym. Bull. 70, 2547–2567 (2013). https://doi.org/10.1007/s00289-013-0971-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-013-0971-7