Abstract

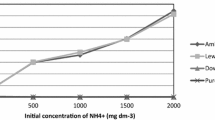

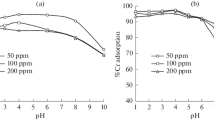

In the present study, the recovery of metal ions from industrial solid residues from a galvanoplasty industry (Rio de Janeiro, Brazil) was investigated by cationic and anionic ion exchange resins. The electroplating residues were composed of the metals Cu2+, Fe3+, Al3+, Ni2+, and Cr3+. The studies of sorption were conducted under batch and column conditions. Based on these studies, the sorption parameters and the breakthrough curves for both resins were determined. Studies of the sorption equilibrium and kinetics were also performed. The maximum sorption capacities q e (mg g−1) of the cationic resin were: Cu2+: 1.9, Fe3+: 0.6 and Al3+: 0.4. For the anionic resin, the maxim values of q e were Cu2+: 0.4 and Fe3+: 0.1. The Freundlich model was more adequate to describe the ion exchange equilibrium and the sorption mechanism fit the pseudo second-order kinetic model for both resins. The breakpoint of Cu2+ (100 ppm) occurred after passing 1,860 and 2,220 cm3 of residue solution through 20.0 g of the resins (column with h:6.0 cm and d:4.3 cm, flow rate: 60 cm3 min−1). The column regeneration was carried out for five sorption–desorption cycles using H2SO4 2.4 mol L−1 (cationic) and HCl 2.0 mol L−1 (anionic).

Similar content being viewed by others

References

Li C, Xie F, Ma Y, Cai T, Li H, Huang Z, Yuan G (2010) Multiple heavy metals extraction and recovery from hazardous electroplating sludge waste via ultrasonically enhanced two-stage acid leaching. J Haz Mat 178:823–833

Magalhães JM, Silva JE, Castro FP, Labrincha JA (2004) Effect of experimental variables on the inertization of galvanic sludges in clay-based ceramics. J Haz Mat 106B:139–147

Aguiar MRCM, Novaes AC, Guarino AWS (2002) Removal of heavy metals from wastewaters by aluminosilicate. Quim Nova 25:1145–1154

Nagendran A, Vijayalakshmi A, Arockiasamy DL, Shobana KH, Mohan D (2008) Toxic metal ion separation by cellulose acetate/sulfonated poly(ether imide) blend membranes: effect of polymer composition and additive. J Haz Mat 155:477–485

Lee JC, Pandey BD (2012) Bio-processing of solid wastes and secondary resources for metal extraction—a review. Waste Manage (Oxford) 32:3–18

Cavaco SA, Fernandes S, Quina MM, Ferreira LM (2007) Removal of chromium from electroplating industry effluents by ion exchange resins. J Haz Mat 144:634–638

Cavaco SA, Fernandes S, Augusto CM, Quina MM, Gando-Ferreira LM (2009) Evaluation of chelating ion-exchange resins for separating Cr(III) from industrial effluents. J Haz Mat 169:516–523

Dabrowski A, Hubicki Z, Podkoscielny P, Robens E (2004) Selective removal of the heavy metal ions from waters and industrial wastewaters by ion-exchange method. Chemosphere 56:91–106

Juang R-S, Kao H-C, Chen W (2006) Column removal of Ni(II) from synthetic electroplating waste water using a strong-acid resin. Sep Purif Technol 49:36–42

Juang R-S, Kao H-C, Liu F-Y (2006) Ion exchange recovery of Ni(II) from simulated electroplating waste solutions containing anionic ligands. J Haz Mat B 128:53–59

Lee H, Kuan Y-C, Chern J-M (2006) Factorial experimental design for recovering heavy metals from sludge with ion-exchange resin. J Haz Mat B 138:549–559

Panayotova T, Dimova-Todorova M, Dobrevskyn I (2007) Purification and reuse of heavy metals containing wastewaters from electroplating plants. Desalination 206:135–140

Sahni SK, Reedijk J (1984) Coordination chemistry of chelating resins and ion exchangers. Coord Chem Rev 59:1–139

Dutra PB, Toci AT, Riehl CAS, Barbosa CR, Coutinho FMB (2005) Adsorption of some elements from hydrochloric acid by anion exchange. Eur Polym J 41:1943–1946

Novais et al (2006) Synthesis of porous copolymers network based on methyl methacrylate and evaluation in the Cu (II) extraction. Mat Let 60:1412–1415

Costa PA, Teixeira VG (2010) Influence of the matrix porosity on the synthesis and adsorption behavior of dithiocarbamate styrenic resins toward zinc(II) and cadmium(II) ions. J Appl Polym Sci 116:3070–3078

Costa LC, Gomes AS, Coutinho FMB, Teixeira VG (2010) Chelating resins for mercury extraction based on grafting of polyacrylamide chains onto styrene divinylbenzene copolymers by gamma irradiation. React Funct Polym 70:738–746

Souza MAV, Santa Maria LC, Costa MAS, Hui WS, Costa LC, Araujo Filho HC, Amico SC (2011) Synthesis, characterization and evaluation of phosphorylated resins in the removal of Pb2+ from aqueous solutions. Pol Bul 67:237–249

Diogo DD, Herbst MH, Ribeiro R, Teixeira VG (2011) The role of matrix porosity in the adsorption of Cu(II) by amidoxime chelating resins: an electron paramagnetic resonance study. React Funct Polym 71:721–727

Helfferich FG (1995) Ion exchange, 2nd edn. Dover Publications, New York, pp 73–74

ASTM D 1895-69 (1975) Annual Book of ASTM, Philadelphia

Peng G, Tian G (2010) Using electrode electrolytes to enhance electrokinetic removal of heavy metals from electroplating sludge. Chem Eng J 165:388–394

Wołowicza A, Hubicki Z (2010) Effect of matrix and structure types of ion exchangers on palladium(II) sorption from acidic medium. Chem Eng J 160:660–670

El-Sofany EA (2008) Removal of lanthanum and gadolinium from nitrate medium using Aliquat-336 impregnated onto Amberlite XAD-4. J Haz Mat 153:948–954

Dizge N, Keskinler B, Barlas H (2009) Sorption of Ni(II) ions from aqueous solution by Lewatit cation-exchange resin. J Haz Mat 167:915–926

Kołodyńska D (2010) The effects of the treatment conditions on metal ions removal in the presence of complexing agents of a new generation. Desalination 263:159–169

Wołowicza A, Hubicki Z (2011) Comparison of strongly basic anion exchange resins applicability for the removal of palladium(II) ions from acidic solutions. Chem Eng J 171:206–215

Dotto GL, Vieira MLG, Gonçalves JO, Pinto LAA (2011) Removal of acid blue 9, food yellow 3 and FD&C yellow n° 5 dyes from aqueous solutions using activated carbon, activated earth, diatomaceous earth, chitin and chitosan: equilibrium studies and thermodynamic. Quim Nova 34:1193–1199

Ho YS (2006) Review of second-order models for adsorption systems. J Haz Mat B 136:681–689

Langes (1985) Handbook of chemistry, 13th edn. Mc Gray Hill Book Company, USA

Shek T-H, Ma A, Lee VKC, McKay G (2009) Kinetics of zinc ions removal from effluents using ion exchange resin. Chem Eng J 146:63–70

Wołowicz A, Hubicki Z (2009) Palladium(II) complexes adsorption from the chloride solutions with macrocomponent addition using strongly basic anion exchange resins, type 1. Hydrometallurgy 98:206–212

Priya PG, Basha CA, Ramamurthi V, Begum SN (2009) Recovery and reuse of Ni(II) from rinsewater of electroplating industries. J Haz Mat 163:899–909

Acknowledgments

We thank the Fundação Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (PRODOC/CAPES), Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) and Fundação de Amparo a Pesquisa do Estado do Rio de Janeiro (FAPERJ) for financial support. We also express our thanks to Lanxess–Bayer Chemical for donating the ion exchange resins.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Evaristo, A.A.A., Santos, K.C.R., Costa, L.C. et al. Evaluation of ion exchange resins for recovery of metals from electroplating sludge. Polym. Bull. 70, 2239–2255 (2013). https://doi.org/10.1007/s00289-013-0944-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-013-0944-x