Abstract

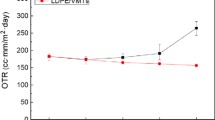

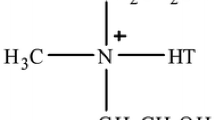

The compatibilization effects provided by maleic anhydride (MA), itaconic acid (IAc), itaconic anhydride (IA), and 2-[2-(dimethylamine)-ethoxy]ethanol (DMAE) functionalized polyethylenes for forming high density polyethylene (HDPE)-based nanocomposites were studied and compared. IAc and IA were grafted into HDPE by melt mixing to obtain functionalized polyethylenes (HDPEgIAc and HDPEgIA) and amino alcohol functionalized polyethylene was prepared by reaction of commercial HDPEgMA with DMAE in the melt to form polyethylene-grafted dimethyl-amine-ethoxy-ethanol (PEgDMAE). Nanocomposites were prepared by melt processing using a twin screw extruder by blending polyethylene and these compatibilizers with a quaternary ammonium surfactant-modified montmorillonite clay (Nanomer I28E). FTIR characterization confirmed the formation of these compatibilizers and confirmed the reaction between HDPEgMA and the amino alcohol. All the compatibilized nanocomposites had better clay exfoliation compared to the uncompatibilized HDPE nanocomposites. Barrier properties, X-ray diffraction and transmission electron microscopy results showed the following order of their performance as a compatibilizer: PEgDMAE > HDPEgAI > HDPEgAcI > HDPEgMA. This behavior was attributed to the specific interactions between the anionic surface of the clay and the functionality of the compatibilizer. Samples with higher clay content showed poorer clay dispersion or intercalation which was attributed to possible clay saturation when the van der Waals attractive interactions between the clay layers become dominant when the distance between them was small enough at a certain concentration of clay. A noticeable reduction in the degree of crystallinity with the incorporation of nanoclay was observed by thermal analysis whereas the melting temperature did not change noticeably.

Similar content being viewed by others

References

Leong YW, Mohd Ishak ZA, Ariffin A (2004) Mechanical and thermal properties of talc and calcium carbonate filled polypropylene hybrid composites. J Appl Polym Sci 91:3327

Winey K, Vaia R (2007) Polymer nanocomposites. MRS Bull 32:314

Palza H, Vergara R, Yazdani M, Quijada R (2009) Polypropylene/clay nanocomposites: effect of different clays and compatibilizers on their morphology. J Appl Polym Sci 112:1278

Causin V, Marega C, Marigo A, Ferrara G, Ferraro A, Selleri RJ (2008) Structure-property relationships in isotactic poly(propylene)/ethylene propylene rubber/montmorillonite nanocomposites. Nanosci Nanotechnol 8:1823

Ray S, Okamoto M (2003) Polymer/layered silicate nanocomposites: a review from preparation to processing. Prog Polym Sci 28:1539

Manias E, Touny A, Wu L, Strawhecker K, Lu B, Chung TC (2001) Polypropylene/montmorillonite nanocomposites. Review of the synthetic routes and materials properties. Chem Mater 13:3516

Garcia LD, Picazo O, Merino JC, Pastor JM (2003) Polypropylene–clay nanocomposites: effect of compatibilizing agents on clay dispersion. Eur Polym J 39:945

Van de VK, Kiekens P (2001) Influence of fibre and matrix modifications on mechanical and physical properties of flax fibre reinforced poly(propylene). Macromol Mater Eng 286:237

Moncada E, Quijada R, Lieberwirth I, Yazdani M (2006) Usse of PP grafted with itaconic acid as new compatibilizer for PP/Clays nanocomposites. Macromol Chem Phys 207:1376

Yazdani M, Vega H, Quijada R (2001) Melt functionalization of polypropylene with methyl esters of itaconic acid. Polymer 42:4751

Cui L, Paul DR (2007) Evaluation of amine functionalized polypropylenes as compatibilizers for polypropylene nanocomposites. Polymer 48:1632

Sanchez-Valdes S, Mendez J, Medellın F, Ramırez E, Martınez J, Ramos L, Mondragon M, Lopez M, Garcıa M (2010) Evaluation of different amine functionalized polyethylenes as compatibilizers for polyethylene film nanocomposites. Polym Int 59:704

Sanchez-Valdes S, Ramirez-Vargas E, Ramos de Valle LF, Mendez-Nonell J, Medellin-Rodriguez FJ, Martinez-Colunga JG, Vazquez-Rodriguez S, Betancurt-Galindo R, Ibarra-Alonso MC (2012) Itaconic acid and amino alcohol functionalized polyethylene as compatibilizers for polyethylene nanocomposites. Compos B 43:497

Krivoguz YM, Pesetskii S, Jurkowski B, Krivoguz Y, Olkhov Y (2001) Solubility of additives: grafting of itaconic acid onto LDPE by reactive extrusion. J Appl Polym Sci 81:3439

Koo CM, Kim SO, Chung IJ (2003) Study on morphology evolution, orientational behavior, and anisotropic phase formation of highly filled polymer-layered silicate nanocomposites. Macromolecules 36:2748

Chen L, Wong SC, Pisharath S (2003) Fracture properties of nanoclay-filled polypropylene. J Appl Polym Sci 88:3298

Bailly M, Kontopoulou M (2009) Preparation and characterization of thermoplastic olefin/nanosilica composites using a silane-grafted polypropylene matrix. Polymer 50:2472

Sharif-Pakdaman A, Morshedian J, Jahani Y (2012) Influence of the silane grafting of polyethylene on the morphology, barrier, thermal, and rheological properties of high-density polyethylene/organoclay nanocomposites. J Appl Polym Sci 125:E305

Gopakumar TG, Lee JA, Kontopoulou M, Parent JS (2002) Influence of clay exfoliation on the physical properties of montmorillonite/polyethylene composites. Polymer 43:5483

Wunderlich B (1973) Macromolecular physics. Academic Press, New York

Polyakova A, Liu RYF, Schiraldi DA, Hitner A, Baer EJ (2001) Oxygen barrier properties of copolymers based on ethylene terephthalate. J Polym Sci Part B Polym Phys 39:1889

Dumont M, Reyna A, Emond J, Bousmina M (2007) Barrier properties of polypropylene/organoclay nanocomposites. J Appl Polym Sci 103:618

Acknowledgments

The authors gratefully acknowledge the financial support of CONACyT through project: CB-104865. The authors would like to thank Aracely-Nospanco, Alejandro-Espinoza, Jesus-Rodriguez, Fabian-Chavez, Francisco-Zendejo, Jose Lopez-Rivera, Patricia-Siller, and Miriam-Lozano for their technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sanchez-Valdes, S., Ramírez-Vargas, E., de Valle, L.F.R. et al. Effect of functionalized polyethylenes on clay dispersion in high density polyethylene nanocomposites. Polym. Bull. 70, 535–547 (2013). https://doi.org/10.1007/s00289-012-0850-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-012-0850-7