Abstract

Estimation of electrical conductivity (EC) in nutritive solutions is generally used to evaluate its suitability for irrigation. EC is a measure of osmotic potential of water applied via irrigation which affects growth and yield of irrigated crops. Generally, the estimation is achieved multiplying the total mass concentration by an empirical coefficient linearly relating it to EC. Different electrolytes with equal mass concentration induce different electrical conductivities which lead to inaccuracy when estimating EC of multiple salts in solution. The article presents the rationale and derivation of a model relating partial mass concentration (NSC) of several nutritive salts (NS) in solution to its resulting EC and ratio of nutritive elements (NE). Partial mass concentration of eight nutritive salts used in the composition of nutritive solutions has been co-related to resulting EC. Individual co-relations led to nonlinear regressions resulting in eight polynomial equations combined in a multivariable function describing EC in terms of NSC. Nutrient concentration NC (considering multiple NE in solution) and its resulting EC are described by a model relating them to NSC: (EC, NC1, NC2,… NC n ) = f(NSC1, NSC2,…, NSC n ). The model estimates EC with considerable accuracy (co-relation of estimation vs. measurement—linear regression: R2 = 0.9986) and integrates the fertigation decision support system—DSS-FS fertigation simulator. This provides a more effective and reliable method of estimating the EC which will, ultimately, impact management decisions.

Similar content being viewed by others

Introduction

It is well established in the scientific literature that saline water in the root zone induces osmotic changes and directly affects nutrient uptake as Na+-reducing K+ uptake or by Cl−-reducing NO3− uptake (Cornillon and Palloix 1997; Halperin et al. 2003). Different plants show different symptoms and behavior during salt stress and other environmental stresses, for example, salt accumulation on the leaf reduces photosynthesis and growth (Sudhir and Murthy 2004). Therefore, it is important to consider the resulting salinity when planning nutritive solutions for irrigation (Moreira Barradas et al. 2014a, b). A common way of determining the concentration of salts in solution and its influence on the osmotic potential is to relate it to the resulting EC which can be measured resorting to conductometers.

The relationship between electrical conductivity (EC) and total dissolved solids (TDS) has already been modeled by other authors resorting to linear regressions (American Public Health Association 1992; Abrol et al. 1988; USDA Salinity Laboratory Staff 1954). The concentration of total dissolved solids (TDS) (g/l) can be estimated when multiplying EC (dS/m) by an empirically determined coefficient (American Public Health Association 1992, standard method 2510) whose value has been determined and varies between 0.55 and 0.9. One of the most commonly used values for this coefficient is 0.64 (TDS = 0.64 EC). Although this adjustment is only valid for EC < 5 dS/m (Abrol et al. 1988; USDA Salinity Laboratory Staff 1954), it is acceptable for irrigation purposes as most of the crops are intolerant for EC above that limit.

Nutritive solutions are composed by multiple salts (say nutritive salts NS as they are sources of nutrients) with different influence on osmotic potential measured by the electrical conductivity. Therefore, a model was developed integrating information on the partial concentration of all different NS in solution—NSC (ppm). This new model aims to estimate the solutions resulting EC with higher level of accuracy than the estimation performed by other existing models while defining the nutrient ratio (NR). NR indicates a comparative proportion of nitrogen to phosphate to potash to other nutrients in solution. For example, a 15–10–5 fertilizer has a ratio N–P–K of 3–2–1, and a 0.08–0.012–0.04 nutritive solution has a ratio of 2–3–1.

The article being presented introduces the development of an empirical model to estimate electrical conductivity and necessary partial nutritive salt concentration NSC [NSC1: NSC n ] for a desired nutrient ratio in solutions made up to n nutritive salts (NS i ) providing sufficient accuracy and precision for practical application, namely integrating decision support systems for fertigation management.

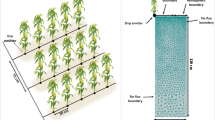

In Fig. 1 is shown the DSS-FS (Moreira Barradas et al. 2012) interface running the model described in this article. DSS-FS simulation allows estimating how different nutritive salts (injected into the irrigation water) modify an array of parameters such as: EC, pH, nutrient ratio, TDS, etc.

DSS-FS interface for nutritive solutions formulation (Moreira Barradas et al. 2012)

The article describes the DSS-FS algorithm used to accurately estimate the required partial concentration of each nutritive salt generate a desired nutrient ratio and EC of nutritive solutions. Other important indicators such as Fertigation Efficiency Index (FEI) (Moreira Barradas et al. 2012) and Sodicity SAR are also assessed by DSS-FS software.

Materials and methods

Electrical conductivity EC is defined as the reciprocal of resistivity ρ. It is expressed in Siemens per meter (S/m) usually at a reference temperature of 25 °C as temperature affects its magnitude (Eq. 1).

The electrical conductivity of a solution varies with the concentration of the electrolytes in it, however, this is not directly proportional, and therefore, the ions in the solution may have different abilities to transport electric current depending on the concentration in which they are present in the solution.

Therefore, the term molar conductivity Λm, (which is the ratio electrical conductivity k i to molar concentration c i —Eq. 2), appears to be very opportune as it describes the electrolyte’s behavior when transporting electric current through a wide range of molarities in electrolyte solutions.

According to the Debye-Hückel limiting law (see Eq. 3), it is easy to understand why the ions lose their ability to transport electric current with concentration.

where \({{\upgamma }}_{\pm }\) mean activity coefficient of the ions in solution (–). A solvent-dependent constant (Awater = − 0.5085). B electrolyte-dependent constant (–). I ionic strength (mol/l). z+ ionic charge of the cations (–). z− ionic charge of the anions (–). d effective hydrated diameter of the ion in solution (Å).

The Ionic strength I is described by Eq. 4

with c i molar concentration (mol/l). z i ionic charge of the ions in solution (–).

The ionic activity a is the product of molar concentration c i by the activity coefficient γ (Eq. 6)

The relationship between γ and I (see Eq. 3) can be easily visualized in Fig. 2.

By the graph of Fig. 2, it is clear that ionic activity decreases with concentration. The individual ability of the ions to transport electric current follows the same pattern.

The considerations above relating molar conductivity to ionic activity are easily verified according to the nonlinear law for strong electrolytes proposed by Kohlraush (1875). The molar conductivity Λm is maximum at infinite dilution (\({{\Lambda }}_{\text{m}}^{o}\)) and decreases with concentration c i according to Eq. 6

where K is the Kohlrausch coefficient, which depends mainly on the stoichiometry of the specific salt in solution and \({{\varvec{\Lambda}}}_{m}^{o}\) the molar conductivity Λm at infinite dilution, also called limiting molar conductivity. This property explains why increments on salt concentration results in gradually smaller increments on EC.

The electrical conductivity of strong electrolytes increases with concentration but not linearly. For that reason, the rate of EC increment also decreases with concentration.

Moreira Barradas et al. (2012) obtained a correlation between EC and concentration of different nutritive salts used in fertigation (Fig. 3).

Correlation between concentration and EC in eight different salts (Moreira Barradas et al. 2012)

Figure 4 shows a relationship between individual salt concentration and EC of eight electrolytes commonly used in fertigation. The results have been obtained resorting to a conductometer multi 350i (ion-selective electrode) which allows pH, EC (resolution: 1 µS/cm) and DO (dissolved oxygen) measurements with temperature compensation (Fig. 4).

The curves relating EC to concentration are linear at very low dilutions becoming polynomial with increasing concentration as shown by the polynomial equations of the curves in Fig. 4. These curves are represented by the general Eq. 7 when using the specific coefficients for each particular salt. These coefficients (see Table 1) were obtained from the analysis of the plot of concentration vs. EC shown in Fig. 4.

The additive property of anions and cations on resulting EC can be used to estimate with great accuracy the EC of a solution of several different salts based on an empiric solution.

It was possible to obtain eight nonlinear regressions from the plots shown in Fig. 4 (one regression for each curve) expressing a mathematical relationship between concentration and EC. This mathematical relationship is described by Eq. 7.

with NSC i mass concentration (g/l) of nutritive salt i. aa-, a-, b- and c-specific salt coefficients (described in Table 1).

The equation described above and its coefficients have been linearly combined into Eq. 8, which describes the resulting EC of multiple electrolytes in solution.

With

The multi-electrolyte coefficients are given as follows:

*assuming the use of salts of only nutritive ions (NO3−;K+; Ca2+ ; etc),

**assuming the use of salts of some non-nutritive ions such as Cl− or bicarbonate COOH−.

If the salts being used have no chlorides or no other non-nutritive elements in their composition, then the following equivalence is verified and TDS can also be related to the sum of array elements NEC[1: n]

The validity of Eq. 8, has been assessed by statistical analysis of 77 solutions of 8 different electrolytes randomly prepared. The NSC i array (i = {1:8}) was defined in each solution resorting to EXCEL function “randbetween(0, 2)” with concentrations between 0 and 2 g/l and TDS < 5 g/l.

To plan a desired partial concentration NEC[1: n] of nutritive elements in solution implies an accurate estimation of NSC[1: n] of n salts in solution. Determining the correct array NSC[1: n] in solution for a desired array of concentrations of n nutritive elements NEC[1: n] can be trivially obtained formulating the problem with a system of equations (see Table 2). Table 2 is a system of six equations to six unknown represented by a quadratic matrix (6 × 6) showing six nutritive salts NS[1:6] with known composition expressed in mass percentages of six nutritive elements NE[1:6].

The fraction of NEC i to TDS expresses the ratio of nutrients NER in solution (see Eq. 17)

Equation 18 describes NER* as a fraction of TDS not including the non-nutritive elements such as Cl− or carbonates.

Crop demand for nutrients changes through the growing season (Hochmuth 2001). It is a common practice between fertigation professionals (Almeria–Spain and Estremadura region—west Portugal) to modify their nutritive solution formulations along the growing cycles of their crops. This happens because they usually identify different needs in terms of salts in solution by observing different plant nutritional deficiencies in different stages of the growing cycle when using a single nutritive solution (e.g., Hoagland solution or other variant).

The array NER*[1: n] describes the ratio of nutrients to each other in solution and evaluates the suitability of each particular formulation for different purposes of nutrient demand such as different stages of the phenologic cycle (vegetative development, blossom, fruit growth, fruit ripe, etc) independently of the absolute concentration TDS.

Table 2 shows the desired array of concentrations NEC[1:6] (ppm) and desired nutritive element ratio NER[1:6] (%). which relates NECi to TDS (see Eq. 17).

The percentage of NE i in NS j is given by P ij .

Conversely, it will be necessary to estimate the necessary array of nutritive salt concentrations NSC[1: n] that generates the desired array of nutrient ratios NER[1:6] and their individual concentrations NEC[1:6] at a desired solution EC.

Using a case scenario with an array of available salts NS[1:6] and an array of required nutrient concentration NEC[1:6] :

NS[1:6] = {KNO3; NH4H2PO4; CaNO3; MgSO4; K2SO4; NH4NO3}.

NEC[1:6] = {15;5;30;10;5;10}.

The values of NSC[1:6] are algebraically determined solving the system of equations (represented by the matrix shown in Table 2) resorting to a Cramer’s rule (Gong et al. 2002).

See results in Table 3.

Formulating a nutritive solution with a specific EC and NER[1:n]

Figure 5 shows an algorithm formulating a nutritive solution with specific EC and ratio of nutrients NER[1:n] iteratively resorting to Eq. 8 combined with an empirical correlation TDS to EC.

The inputs are the desired EC, NER[1: n] and available fertilizers NS[1: n] for the formulation.

The output is the array of concentrations of n fertilizers NSC[1: n] required to generate the specified inputs: EC and NER[1: n].

Considering the array of concentrations of the required salts in solution NSC as a function of NER and EC: NSC[1: n] = f{EC; NER[1: n]}.

Let α (an empiric coefficient also adopted by other authors to convert TDS to EC) be set as α = 0.64 and ε (the error defined for estimation) customized as ε = 0.01.

Desired EC and NER[1: n] is given by step 2.6 of the iteration with NSC[1:6] in solution.

Results and discussion

The resulting EC was both measured using a conductometer Multi 350i and estimated through Eq. 8. Afterwards, a correlation between measured and estimated results was created to verify the accuracy of the estimation based on the coefficient of determination R2.

The groups of observed and estimated EC were compared through a t test and an analysis of variance (ANOVA single factor) for an interval of confidence of 95%.

Figure 6 shows the correlation measured vs. estimated EC by the proposed methodology (Eq. 8).

Correlation estimation (Eq. 8) vs observation

The correlation above shows a considerably high accuracy of estimation resorting to Eq. 8.

Figure 7 shows the correlation between the observed results and estimation according to Abrol et al. (1988). This methodology has been adopted by several authors (USDA Salinity Laboratory Staff 1954; American Public Health Association 1992).

Correlation estimation (Abrol et al. 1988) and many others vs. measured results

The analysis of variance (ANOVA single factor for 95% interval of confidence) performed between the estimated values using the proposed methodology described by Eq. 8 and the measured values shows that we can assume no differences between the estimation and the observation when using the proposed methodology. These differences are to be considered when using the methodology proposed by other authors—Abrol et al. (1988), USDA Salinity Laboratory Staff (1954), American Public Health Association (1992)—Table 4 shows that the null hypothesis is to be rejected in this case.

A correlation based upon multiple regressions using EXCEL statistical analysis was also performed with a R2 of 0.9986, however, its coefficients are only valid within the experimental set and cannot be used to estimate random combinations outside the experimented scenario where the estimation via Eq. 12 is still valid.

EC estimated via statistical regression will be given by Eq. 20 with X[1:8] (corresponding to NSC[1:8]) and coefficient[1:8] as shown in Table 5, however, valid only inside the experimented scenario as opposed to Eq. 8 valid also in any random combination outside the experimented scenario.

The EC correlation of measured results and estimation via statistical regression is given by Fig. 8.

RMSE and NRMSD were also used to evaluate the performance of the model as opposed to the one proposed by other authors.

Table 6 shows RMSE and NRMSD between estimation (by Eq. 8 vs other authors) and the observation.

Practical application

The algorithm described in this paper integrates the decision support system—DSS-FS Fertigation Simulator (Moreira Barradas et al. 2012). Data from farms where the DSS-FS software was used as the primary consulting system has been analysed. The results were presented by (Moreira Barradas et al. 2014a, b) proving this system to be user-friendly and a valuable tool to increase production in considerable amounts, saving 20–30% in input factors and energy as reported by the majority of users (Moreira Barradas et al. 2014a, b).

Sustainability

The effects of fertigation using the DSS-FS Fertigation Simulator on soil health parameters were also assessed by Moreira Barradas et al. (2014a, b). Physicochemical properties of a Haplic Chernozem soil were measured while applying fertigation in natural grassland during the growing season in a hemiboreal climate with irrigation management based on the DSS-FS model. There has been no evidence of soil degradation in any of the parameters where this study was focused. This does not imply that the use of other methods to estimate resulting EC (namely the empirical relation proposed by the USDA) is harmful. Nevertheless, the proposed methodology introduces a more accurate technique integrating an algorithm also able to formulate customized nutritive solutions.

Conclusion

Using a simple correlation factor (0.64 as the most commonly used value) shows the null hypothesis rejected after analysis of variance (ANOVA) with also a considerable high RMSE result (RMSE = 1.632; NRMSD = 0.3479).

Equation 8 (proposed in this work) is an empirical solution with a considerable level of accuracy and precision (R2 = 0.9982; ANOVA—acceptance of null hypothesis for an interval of confidence of 95%; RMSE = 0.054; NRMSD = 0.0115), that is particularly interesting to be used when relating EC to mass concentration. It also shows itself a convenient solution when operating non-pure electrolytes (fertilizers) where reassessment of individual coefficients aa, a, b and c might be a necessity from time to time.

Therefore, the algorithm proposed in Fig. 5 integrating Eq. 8 has been demonstrated as an extraordinary tool (when integrating DSS) to formulate nutritive solutions having a specified value of EC and a desired nutrient ratio according to an array NS[1:N] of available fertilizers (Table 5).

Abbreviations

- DO:

-

Dissolved oxygen

- DSS:

-

Decision support system

- DSS-FS:

-

Decision support system-fertigation simulator

- EC:

-

Electrical conductivity

- FEI:

-

Fertigation Efficiency Index

- NC:

-

Nutrient concentration

- NE:

-

Nutritive elements

- NER:

-

Nutritive element ratio

- NR:

-

Nutrient ratio

- NS:

-

Nutritive salts

- NSC:

-

Nutritive salt concentration

- P :

-

Ratio of a given nutritive element in a given salt

- SAR:

-

Sodium adsorption ratio

- TDS:

-

Total dissolved salts

- αα:

-

An empiric coefficient also adopted by other authors to convert TDS to EC

References

Abrol IP, Yadav JSP, Massoud FI (1988) Salt-affected soils and their management. FAO Soils Bulletin No. 39. FAO Roma

American Public Health Association (1992) Standard methods for the examination of water and wastewater. 18th edn, Washington, DC

Cornillon P, Palloix A (1997) Influence of sodium chloride on the growth and mineral nutrition of pepper cultivars. J Plant Nutr 20:1085–1094

Gong Z, Aldeen M, Elsner L (2002) A note on a generalized Cramer’s rule. Linear Algebra Appl 340:253–254. https://doi.org/10.1016/S0024-3795(01)00469-4

Halperin ST, Gilroy S, Lynch JP (2003) Sodium chloride reduces growth and cytosolic calcium, but does not affect cytosolic pH, in root hairs of Arabidopsis thaliana L. J Exp Bot 54:1269–1280

Hochmuth G (2001) Nutrient solution formulation for hydroponic (Perlite, Rockwool and NFT) tomatoes in Florida, nutrient solutions. North Florida Research and Education Center, Suwannee Valley, Live Oak

Kohlrausch F (1875) Law of independent ionic mobilities. Ann Phys. 156. 601–618. Leipzig

Moreira Barradas JM, Matula S, Dolezal F (2012) A decision support system-fertigation simulator (DSS-FS) for design and optimization of sprinkler and drip irrigation systems. Comput Electron Agric 86:111–119

Moreira Barradas J, Abdelfattah A, Matula S, Dolezal F (2014a) Effect of fertigation on soil salinization and aggregate stability. J Irrig Drain Eng https://doi.org/10.1061/(ASCE)IR.1943-4774.0000806, (05014010)

Moreira Barradas J, Matula S, Dolezal F, Mekonnen GB, Mihalikova M, Chala AT (2014b) Practical application of DSS-FS fertigation simulator in several crops world wide. Irr Drain. https://doi.org/10.1002/ird.1832/full

Sudhir P, Murthy SDS (2004) Effects of salt stress on basic processes of photosynthesis. Photosynthetica 42:481–486

USDA Salinity Laboratory Staff (1954) Diagnosis and improvement of Saline and Alkali Soils. Handbook 60, USDA, Washington DC, p 160

Acknowledgements

This study was partly supported by the research Grant No. MSM6046070901 Sustainable agriculture, quality of agricultural products, sustainable use of natural and landscape resources of the Czech University of Life Sciences in Prague, financed by the Ministry of Education, Youth and Sports of the Czech Republic.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by E. Fereres.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Moreira Barradas, J.M., Dida, B., Matula, S. et al. A model to formulate nutritive solutions for fertigation with customized electrical conductivity and nutrient ratios. Irrig Sci 36, 133–142 (2018). https://doi.org/10.1007/s00271-018-0569-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00271-018-0569-9