Abstract

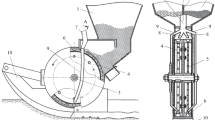

Fertigation with microirrigation systems is increasing in popularity. Uniformity of fertigation is important for many reasons. Field experiments were conducted to evaluate the effects of injector types and emitters on fertigation uniformity by simultaneously measuring the distributions of water application, solution concentration, and fertilizer applied within a subunit of microirrigation system. Three conventionally used injectors, a water-driven piston proportional pump, a venturi device, and a differential pressure tank, were evaluated with three different emitters. The results indicated that both manufacturing variability of emitters and injector types had a very significant effect on the uniformity of fertilizer applied, while the uniformity of water application was mainly dependent on emitter type. The uniformity of solution concentration was dependent on injection methods. Emitters having a higher manufacturer’s variation produced a more nonuniform distribution of water application and fertilizer applied. For a given emitter type, a differential pressure tank produced considerably higher coefficients of variation (Cv) for water application and fertilizer applied than a proportional pump or a venturi injector because a differential pressure tank released fertilizer in a decreasing rate with time. To obtain a uniform fertigation distribution, an injector that can inject fertilizers in a constant rate is recommended. The relationship between water application uniformity and fertigation uniformity for a microirrigation system was established for different injection methods. Cv for fertilizer applied was very close to water application Cv for a microirrigation system using a proportional pump or a venturi injector as an injection device. However, fertilizer Cv for a differential pressure tank was approximately double of the water application Cv. The injection method and injector performance should therefore be considered in the design of microirrigation systems.

Similar content being viewed by others

References

ASAE Standards (2003a) EP458. Field evaluation of microirrigation systems, 50th edn. St. Joseph, Mich.: ASAE

ASAE Standards (2003b) S553. Collapsible emitting hose (drip tape)—Specifications and performance testing, 50th edn. St. Joseph, Mich.: ASAE

ASAE Standards (2003c) EP405.1. Design and installation of microirrigation systems, 50th edn. St. Joseph, Mich.: ASAE

Bracy RP, Parish RL, Rosendale RM (2003) Fertigation uniformity affected by injector type. Horttechnology 13:103–105

Bralts VF, Kelly DF, Shayya WH, Segerlind LJ (1993) Finite element analysis of microirrigation hydraulics using a virtual emitter system. Trans ASAE 36:717–725

Chinese Standard (2002) SL103–95: Technical standard for microirrigation systems (in Chinese). China Water Power Press, Beijing

Clark GA, Lamm FR, Rogers DH (2005) Sensitivity of thin-walled drip tape emitter discharge to water temperature. Appl Eng Agric 21:855–863

Hathoot HM, Al-Amoud AI, Mohammad FS (1993) Analysis and design of trickle-irrigation laterals. J Irrig Drain Eng ASCE 119:756–767

Hills DJ, Nawar FM, Waller PM (1989) Effects of chemical clogging on drip tape irrigation uniformity. Trans ASAE 32:1202–1206

ISO (2004) 9261: Agricultural irrigation equipment—emitters and emitting pipe—specification and test methods. International Organization for Standardization

Kang Y, Nishiyama S (1995) Hydraulic analysis of microirrigation subunits. Trans ASAE 38:1377–1384

Nakayama FS, Bucks DA (1981) Emitter clogging effects on trickle irrigation uniformity. Trans ASAE 24:77–80

Solomon K (1979) Manufacturing variation of trickle emitters. Trans ASAE 22:1034–1038, 1043

Talozi SA, Hills DJ (2001) Simulating emitter clogging in a microirrigation subunit. Trans ASAE 44:1503–1509

Townsend JD (1988) Fertigation—uniformity of fertilizer application through drip irrigation systems. In: Proceedings of the 4th international microirrigation congress, Albury-Wodonga, Australia

Wu IP, Yue R (1993) Drip lateral design using energy gradient line approach. Trans ASAE 36:389–394

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 50379058, 50579067).

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by T. Trooien

Rights and permissions

About this article

Cite this article

Li, J., Meng, Y. & Li, B. Field evaluation of fertigation uniformity as affected by injector type and manufacturing variability of emitters. Irrig Sci 25, 117–125 (2007). https://doi.org/10.1007/s00271-006-0039-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00271-006-0039-7