Abstract

Purpose

Remelted highly crosslinked polyethylenes (HXLPEs) were introduced in total knee replacement (TKR) starting in 2001 to reduce wear and particle-induced lysis. The purpose of this study was to investigate the damage mechanisms and oxidative stability of remelted HXLPEs used in TKR.

Methods

A total of 186 posteriorly stabilised tibial components were retrieved at consecutive revision operations. Sixty nine components were identified as remelted HXLPE. The conventional inserts were implanted for 3.4 ± 2.7 years, while the remelted components were implanted 1.4 ± 1.2 years. Oxidation was assessed using Fourier transform infrared spectroscopy.

Results

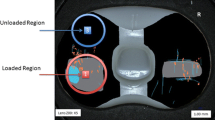

Remelted HXLPE inserts exhibited lower oxidation indices compared to conventional inserts. We were able to detect slight regional differences within the HXLPE cohort, specifically at the bearing surface.

Conclusion

Remelted HXLPE was effective at reducing oxidation in comparison to gamma inert sterilised controls. Additional long-term HXLPE retrievals are necessary to ascertain the long term in vivo stability of these materials in TKR.

Similar content being viewed by others

References

Kurtz SM (2009) UHMWPE biomaterials handbook: ultra-high molecular weight polyethylene in total joint replacement and medical devices, 2nd edn. Academic, Burlington

Kurtz SM, Gawel HA, Patel JD (2011) History and systematic review of wear and osteolysis outcomes for first-generation highly crosslinked polyethylene. Clin Orthop Relat Res 469:2262–2277. doi:10.1007/s11999-011-1872-4

Baker DA, Bellare A, Pruitt L (2003) The effects of degree of crosslinking on the fatigue crack initiation and propagation resistance of orthopedic-grade polyethylene. J Biomed Mater Res A 66:146–154. doi:10.1002/jbm.a.10606

Huot JC, Van Citters DW, Currier JH, Currier BH, Mayor MB, Collier JP (2010) Evaluating the suitability of highly cross-linked and remelted materials for use in posterior stabilized knees. J Biomed Mater Res B Appl Biomater 95:298–307. doi:10.1002/jbm.b.31714

Jasty M, Rubash HE, Muratoglu O (2005) Highly cross-linked polyethylene: the debate is over–in the affirmative. J Arthroplasty 20:55–58

Ries MD (2005) Highly cross-linked polyethylene: the debate is over–in opposition. J Arthroplasty 20:59–62

Hodrick JT, Severson EP, McAlister DS, Dahl B, Hofmann AA (2008) Highly crosslinked polyethylene is safe for use in total knee arthroplasty. Clin Orthop Relat Res 466:2806–2812. doi:10.1007/s11999-008-0472-4

Willie BM, Foot LJ, Prall MW, Bloebaum RD (2008) Surface damage analysis of retrieved highly crosslinked polyethylene tibial components after short-term implantation. J Biomed Mater Res B Appl Biomater 85:114–124. doi:10.1002/jbm.b.30923

Currier BH, Van Citters DW, Currier JH, Collier JP (2010) In vivo oxidation in remelted highly cross-linked retrievals. J Bone Joint Surg Am 92:2409–2418. doi:10.2106/JBJS.I.01006

Muratoglu OK, Wannomae KK, Rowell SL, Micheli BR, Malchau H (2010) Ex vivo stability loss of irradiated and melted ultra-high molecular weight polyethylene. J Bone Joint Surg Am 92:2809–2816. doi:10.2106/JBJS.I.01017

Hood RW, Wright TM, Burstein AH (1983) Retrieval analysis of total knee prostheses: a method and its application to 48 total condylar prostheses. J Biomed Mater Res 17:829–842. doi:10.1002/jbm.820170510

Macdonald D, Sakona A, Ianuzzi A, Rimnac CM, Kurtz SM (2010) Do first-generation highly crosslinked polyethylenes oxidize in vivo? Clin Orthop Relat Res. doi:10.1007/s11999-010-1728-3

Currier BH, Currier JH, Mayor MB, Lyford KA, Van Citters DW, Collier JP (2007) In vivo oxidation of gamma-barrier-sterilized ultra-high-molecular-weight polyethylene bearings. J Arthroplasty 22:721–731. doi:10.1016/j.arth.2006.07.006

Kurtz SM, Hozack W, Marcolongo M, Turner J, Rimnac C, Edidin A (2003) Degradation of mechanical properties of UHMWPE acetabular liners following long-term implantation. J Arthroplasty 18:68–78. doi:10.1054/S0883-5403(03)00292-4

Lewis G (1997) Polyethylene wear in total hip and knee arthroplasties. J Biomed Mater Res 38:55–75

Medel FJ, Kurtz SM, Parvizi J, Klein GR, Kraay MJ, Rimnac CM (2011) In vivo oxidation contributes to delamination but not pitting in polyethylene components for total knee arthroplasty. J Arthroplasty 26:802–810. doi:10.1016/j.arth.2010.07.010

Cornwall GB, Hansson CM, Bowe AJ, Bryant JT (1997) Surface degradation features and microstructural properties of ultra-high molecular weight polyethylene (UHMWPe). J Mater Sci Mater Med 8:303–309

Crowninshield RD, Wimmer MA, Jacobs JJ, Rosenberg AG (2006) Clinical performance of contemporary tibial polyethylene components. J Arthroplasty 21:754–761. doi:10.1016/j.arth.2005.10.012

McKellop HA (2007) The lexicon of polyethylene wear in artificial joints. Biomaterials 28:5049–5057. doi:10.1016/j.biomaterials.2007.07.040

Acknowledgments

This study was supported by the National Institutes of Health (NIAMS) R01 AR47904. Institutional support has been received from Zimmer, Stryker, Stelkast, Sulzer, and the Wilbert J. Austin Professor of Engineering Chair (CMR).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

MacDonald, D.W., Higgs, G., Parvizi, J. et al. Oxidative properties and surface damage mechanisms of remelted highly crosslinked polyethylenes in total knee arthroplasty. International Orthopaedics (SICOT) 37, 611–615 (2013). https://doi.org/10.1007/s00264-013-1796-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00264-013-1796-6