Abstract

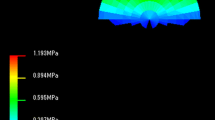

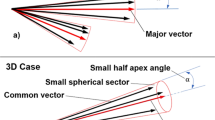

A three-dimensional model of the left acetabulum with inserted threaded cup has been generated, based on the finite element method, to calculate stress patterns in the standing phase during walking. In this study, a hemispherical cup with sharp threads, a parabolic cup with flat threads and a conical cup with sharp threads were analysed and compared. Stress patterns in both implant components and adjacent bony structures were calculated in a directly postoperative situation. The different cups were found to induce different stress patterns, deformations and shifting tendencies. The inlays deform notably and show characteristic rotational movement patterns together with the shell. The inclination angle increases in the hemispherical cup and decreases in the parabolic cup. The conical cup levers outward almost parallel to the bone stock by approximately 0.05 mm. The pole surfaces of the various cups – especially the very convex area next to the threads – induce increased compressive stress in the superior section of the acetabular base. This is increased by a factor of three in the conical cup in comparison to the hemispherical cup and less so in comparison to the parabolic cup. This study illustrates that three-dimensional stress calculations are suitable for procuring additional biomechanical information to augment clinical studies, for evaluating implants and for establishing stability prognoses, especially for newly developed prototypes.

Résumé

Une étude basée sur les éléments finis à partir d’un modèle tridimensionnel d’une hanche gauche a permis de calculer les contraintes générées sur une cupule vissée durant la marche. Pour cette étude, deux cupules différentes ont été analysées, une cupule hémisphérique vissée et une cupule vissée de type conique. Ces différentes cupules entraînent des contraintes différentes. L’angle d’inclinaison augmente dans les cupules hémisphériques et diminue dans les cupules de type parabolique conique. Le bras de levier des cupules de forme conique est pratiquement parallèle à 0,05 mm près au stock osseux. Le contact polaire supérieur de ces différentes cupules entraîne, notamment dans les zones les plus convexes des spires, des augmentations de contraintes au niveau de la partie supérieure de l’acétabulum. Ce phénomène est multiplié par trois dans les cupules coniques en comparaison aux cupules hémisphériques. L’étude tridimensionnelle de ces cupules est fiable, donnant des informations biomécaniques supplémentaires pour les études cliniques, pour l’évaluation des implants et permet de faire un pronostic sur la stabilité de ceux-ci, notamment lorsque l’on développe un nouveau prototype.

Similar content being viewed by others

References

Delaunay CP, Kapandji AI (2004) Einsatz der Zweymüller und Alloclassic-CSF sandgestrahlten Titanschraubpfannen in der primären totalen Hüftendoprothetik. In: Effenberger H (Hrsg). Schraubpfannen. Effenberger, Grieskirchen, pp 205–210

Effenberger H, Böhm G, Huber M, Lintner F, Hofer H (2000) Experimental study of bone-implant contact area with a parabolic acetabular component (Hofer-Imhof). Arch Orthop Trauma Surg 120:160–165

Effenberger H, Imhof M, Witzel U (2001) Gewindedesign von Schraubpfannen. Z Orthop 139:428–434

Effenberger H, Ramsauer T, Dorn U (2004) Factors influencing the revision rate of Zweymueller acetabular cup. Int Orthop 28:155–158

Engh Ch, Zettl-Schaffer KF, Kukita Y, Sweet D, Jasty VM, Bragdom C (1993) Histological and radiographic assessment of well functioning porous-coated acetabular components. J Bone Joint Surg [Am] 75:814–824

Epinette JA, Manley MT, D’Antonio JA, Edidin AA, Capello WN (2003) A 10-year minimum follow-up of hydroxyapatite-coated threaded cups: clinical, radiographic and survivorship analyses with comparison to the literature. J Arthroplasty 18:140–148

Grübl A, Chiari C, Gruber M, Kaider A, Gottsauner-Wolff F (2002) Cementless total hip arthroplasty with a tapered, rectangular titanium stem and a threaded cup. J Bone Joint Surg [Am] 84-A:425–431

Huiskes R (1987) Finite element analysis of acetabular reconstruction. Acta Orthop Scand 58:620–625

Levenstone M, Beaupre GS, Schurmann DJ, Carter DR (1993) Computer simulations of stress-related bone remodelling around non cemented acetabular components. J Arthroplasty 8:595–605

Peterson DR, Crowninshield RD, Brand RA, Johnston RC (1982) An axisymmetric model of actabular components in total hip arthroplasty. J Biomech 15:305–315

Pieringer H, Auersper V, Griessler W, Böhler N (2003) Long-term results with the cementless Alloclassic brand hip arthroplasty system. J Arthroplasty 18:321–328

Pfleiderer M (1997) Mikrobewegungen zementfreier Hüftpfannen im Beckenknochen. Fortschr.-Ber., VDI, Düsseldorf

Pospischill M, Knahr K (2005) Cementless total hip arthroplasty using a rectangular tapered stem. Follow-up for ten to 17 years. J Bone Joint Surg [Br] 87:1210–1215

Ramsauer T, Dorn U (2004) Prinzip und Ergebnisse mit der Hofer-Imhof Schraubpfanne. In: Effenberger H (Hrsg.) Schraubpfannen. Effenberger, Grieskirchen, pp 275–278

Reikeras O, Gunderson RB (2006) Long-term results of HA coated versus HA coated hemispheric press fit cups: 287 hips followed for 11 to 16 years. Arch Orthop Trauma Surg 77:535–542

Vervest TM, Malefijt Jde M, Hendriks JC, Gonsens T, Bonnet M (2005) Ten to twelve-year results with the Zweymuller cementless total hip prosthesis. J Arthroplasty 20:362–368

Witzel U (1996) Mechanische Integration von Schraubpfannen. Ein Beitrag zur hüftendoprothetischen Versorgung. Thieme, Stuttgart

Witzel U (1998) Distribution of stress in a hemispherical RM cup and its bony bed. In: Bergmann EG (Hrsg) Hip-joint surgery, the RM cup. Einhorn-Presse Verlag, Reinbek, pp 29–41

Witzel U, Jackowski, Jöhren P (1998) Analyse der Spannungsverteilung in spongiösen Sinus-Augmentat nach sekundärer Implantation mit Hilfe der finiten Elemente (FEM). Straumann, Freiburg

Witzel U (2000) Die knöcherne Integration von Schraubpfannen. In: Perka C, Zippel H (Hrsg.): Pfannenrevisionseingriffe nach HTEP – Standards und Alternativen. Einhorn-Presse Verlag, Reinbek, pp 11–16

Wolff J (1892) Das Gesetz der Transformation des Knochens. Hirschwald, Berlin

Zweymüller K (2006) Redesigned threaded, double-cone titanium cups yield excellent mid-term results. Orthopedics 29:809–810

Acknowledgements

The authors would like to thank the staff of the Electronic Data Processing Center of the Ruhr University, Bochum for mainframe calculations, also Prof. Dr.-Ing. Welp at the Institute for Construction Technique for donating software and additional computer and printer capacity, also engineers Dr. Ing. Weiss and Dipl. Ing. Wittenschläger for their effective support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Witzel, U., Rieger, W. & Effenberger, H. Three-dimensional stress analysis of threaded cups – a finite element analysis. International Orthopaedics (SICO 32, 195–201 (2008). https://doi.org/10.1007/s00264-006-0308-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00264-006-0308-3