Abstract

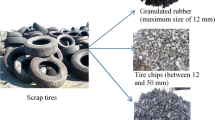

A new geo-environmental approach was proposed to use waste tires in certain engineering applications and thereby reduce the potential impact on the environment. This paper presents a laboratory study on the effect of shredded tires on the physical properties of some sands. Shredded tires were passed through US sieve size 4 and mixed with three different types of sands with varying gradations. Each type of sand was mixed with four different percentages of shredded tires: 10, 20, 30 and 40% by dry weight. Direct shear tests were conducted to study the effect of the shredded tires on the shear strength properties of sands, such as angle of internal friction and shear strength. The addition of shredded waste tires increased both the angle of internal friction and the shear strength of the sands. Additionally, a prediction model was developed to calculate the shear strength of sand due to increasing shredded tire content. The shredded tires improved some engineering properties of sand.

Similar content being viewed by others

References

Ahmed I (1993) Laboratory study on properties of rubber soils. (School of civil engineering report no. FHWA/IN/JHRP 93/4) Purdue University, West Lafayette

ASTM (1985) ASTM D3080: standard test method for direct shear test of soils under consolidated drained conditions. (1985 annual book of ASTM standards, sect. 4, vol. 04.08. Soil and rock; building stones.) American Society for Testing and Materials, Philadelphia

Blumenthal M, Zelibor J (1993) Scraptires used in rubber-modified asphalt pavement and civil engineering applications. In: ASCE (ed) Utilization of waste materials in civil engineering construction. American Society of Civil Engineering, New York, pp 182–201

Bosscher PJ, Edil TB, Eldin N (1993) Construction and performance of shredded waste tire test embankment. (Transportation research rec. no. 1345.) Transport Research Board, Washington, D.C., pp 44–52

Edil T, Bosscher P (1994) Engineering properties of waste tire chips and soil mixture. Geotech Test J 17:453–464

Gray D, Al-Refeal T (1986) Behavior of fabric-versus fiber-reinforced sand. J Geotech Eng ASCE 112:804–820

Humphrey DN, Katz LE, Blumenthal M (1997) Water quality effects of tire chip placed above the ground water table. (ASTM STP 1275: testing soil mixed with waste or recycled materials.) American Standard For Testings and Materials, West Conshohocken, pp 299–313

Lee JH, Saigado R, Bernal A, Lovell CW (1999) Shredded tires and rubber-sand as lightweight backfill. J Geotechnol Geoenviron Eng 125:132–141

Masad E, Taha R, Ho C, Papagiannakis T (1996) Engineering properties of tire/soil mixtures as a lightweight fill material. Geotech Test J 19:297–304

Minnesota Department of Transportation (1994) Using shredded waste tires as lightweight fill material for road subgrades. (Report no. Mn/RD-94/10.) Minnesota Department of Transportation, Maplewood

Tweedie J, Humphrey DN, Sandford T (1998) Tire chips as lightweight backfill for retaining walls—phase II. (Report to the New England transportation consortium.) University of Maine

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Attom, M.F. The use of shredded waste tires to improve the geotechnical engineering properties of sands. Environ Geol 49, 497–503 (2006). https://doi.org/10.1007/s00254-005-0003-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00254-005-0003-5