Abstract

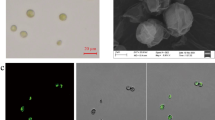

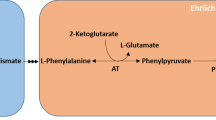

In a water-organic solvent, two-phase conversion system, CoQ10 could be produced directly from solanesol and para-hydroxybenzoic acid (PHB) by free cells of Sphingomonas sp. ZUTE03 and CoQ10 concentration in the organic solvent phase was significantly higher than that in the cell. CoQ10 yield reached a maximal value of 60.8 mg l−1 in the organic phase and 40.6 mg g−1-DCW after 8 h. CoQ10 also could be produced by gel-entrapped cells in the two-phase conversion system. Soybean oil and hexane were found to be key substances for CoQ10 production by gel-entrapped cells of Sphingomonas sp. ZUTE03. Soybean oil might improve the release of CoQ10 from the gel-entrapped cells while hexane was the suitable solvent to extract CoQ10 from the mixed phase of aqueous and organic. The gel-entrapped cells could be re-used to produce CoQ10 by a repeated-batch culture. After 15 repeats, the yield of CoQ10 kept at a high level of more than 40 mg l−1. After 8 h conversion under optimized precursor’s concentration, CoQ10 yield of gel-trapped cells reached 52.2 mg l−1 with a molar conversion rate of 91% and 89.6% (on PHB and solanesol, respectively). This is the first report on enhanced production of CoQ10 in a two-phase conversion system by gel-entrapped cells of Sphingomonas sp. ZUTE03.

Similar content being viewed by others

References

Benga G, Travis BD, Pop VI, Popescu O, Toader S, Holmes RP (1984) The effect of the saturation and isomerization of dietary fatty-acids on the osmotic fragility and water diffusional permeability of rat erythrocytes. Biochim Biophys Acta 775(2):255–259

Bule MV, Singhal RS (2009) Use of carrot juice and tomato juice as natural precursors for enhanced production of ubiquinone-10 by Pseudomonas diminuta NCIM 2865. Food Chem 116:302–305

Cheng B, Yuan QP, Sun XX, Li WJ (2010) Enhanced production of coenzyme Q10 by overexpressing HMG-CoA reductase and induction with arachidonic acid in Schizosaccharomyces pombe. Appl Biochem Biotechnol 160:523–531

Choi JH, Ryu YW, Seo JH (2005) Biotechnological production and applications of coenzyme Q(10). Appl Microbiol Biotechnol 68(1):9–15

Choi JH, Ryu YW, Park YC, Seo JH (2009) Synergistic effects of chromosomal ispB deletion and dxs overexpression on coenzyme Q(10) production in recombinant Escherichia coli expressing Agrobacterium tumefaciens dps gene. J Biotechnol 144(1):64–69

Cluis CP, Burja AM, Martin VJJ (2007) Current prospects for the production of coenzyme Q10 in microbes. Trends Biotechnol 25(11):514–521

Folkers K, Langsjoen P, Willis R, Richardson P, Xia LJ, Ye CQ, Tamagawa H (1990) Lovastatin decreases coenzyme-Q levels in humans. Proc Natl Acad Sci USA 87(22):8931–8934

Gu SB, Yao JM, Yuan QP, Xue PJ, Zheng ZM, Wang L, Yu ZL (2006a) A novel approach for improving the productivity of ubiquinone-10 producing strain by low-energy ion beam irradiation. Appl Microbiol Biotechnol 72(3):456–461

Gu SB, Yao JM, Yuan QP, Xue PJ, Zheng ZM, Yu ZL (2006b) Kinetics of Agrobacterium tumefaciens ubiquinone-10 batch production. Process Biochem 41(8):1908–1912

Ha SJ, Kim SY, Seo JH, Moon HJ, Lee KM, Lee JK (2007a) Controlling the sucrose concentration increases coenzyme Q10 production in fed-batch culture of Agrobacterium tumefaciens. Appl Microbiol Biotechnol 76(1):109–116

Ha SJ, Kim SY, Seo JH, Oh DK, Lee JK (2007b) Optimization of culture conditions and scale-up to pilot and plant scales for coenzyme Q(10) production by Agrobacterium tumefaciens. Appl Microbiol Biotechnol 74(5):974–980

Ha SJ, Kim SY, Seo JH, Sim WI, Moon HJ, Lee JK (2008) Lactate increases coenzyme Q(10) production by Agrobacterium tumefaciens. World J Microbiol Biotechnol 24(6):887–890

Jeya M, Moon HJ, Lee IW, Lee JK (2010) Current state of coenzyme Q(10) production and its applications. Appl Microbiol Biotechnol 85:1653–1663

Kwon YJ, Kaul R, Mattiasson B (1996) Extractive lactic acid fermentation in poly(ethyleneimine)-based aqueous two-phase system. Biotechnol Bioeng 50(3):280–290

Lee JK, Her G, Kim SY, Seo JH (2004) Cloning and functional expression of the dps gene encoding decaprenyl diphosphate synthase from Agrobacterium tumefaciens. Biotechnol Prog 20(1):51–56

Lee PC, Salomon C, Mijts B, Schmidt-Dannert C (2008) Biosynthesis of ubiquinone compounds with conjugated prenyl side chains. Appl Environ Microbiol 74(22):6908–6917

Lin JP, Chen B, Wu JP, Cen PL (1997) L-Lactic acid fermentation in a rotating-disc contactor with simultaneous product separation by ion-exchange. Chin J Chem Eng 5(1):49–55

Lipshutz BH, Mollard P, Pfeiffer SS, Chrisman W (2002) A short, highly efficient synthesis of coenzyme Q(10). J Am Chem Soc 124(48):14282–14283

Li M, Lv WF, Gao XD (2005) Primary investigation on coenzyme Q10 producing bacteria CPU0402. Pharm Biotechnol 12(3):162–166, In Chinese

Matthews PD, Wurtzel ET (2000) Metabolic engineering of carotenoid accumulation in Escherichia coli by modulation of the isoprenoid precursor pool with expression of deoxyxylulose phosphate synthase. Appl Microbiol Biotechnol 53(4):396–400

Mortensen SA, Leth A, Agner E, Rohde M (1997) Dose-related decrease of serum coenzyme Q(10) during treatment with HMG-CoA reductase inhibitors. Mol Aspects Med 18:S137–S144

Negishi E, Liou SY, Xu CD, Huo SQ (2002) A novel, highly selective, and general methodology for the synthesis of 1, 5-diene-containing oligoisoprenoids of all possible geometrical combinations exemplified by an iterative and convergent synthesis of coenzyme Q(10). Org Lett 4(2):261–264

Overvad K, Diamant B, Holm L, Holmer G, Mortensen SA, Stender S (1999) Coenzyme Q(10) in health and disease. Eur J Clin Nutr 53(10):764–770

Park YC, Kim SJ, Choi JH, Lee WH, Park KM, Kawamukai M, Ryu YW, Seo JH (2005) Batch and fed-batch production of coenzyme Q(10) in recombinant Escherichia coli containing the decaprenyl diphosphate synthase gene from Gluconobacter suboxydans. Appl Microbiol Biotechnol 67(2):192–196

Sakato K, Tanaka H, Shibata S, Kuratsu Y (1992) Agitation aeration studies on coenzyme-Q10 production using rhodopseudomonas-sphaeroides. Biotechnol Appl Biochem 16(1):19–28

Shiio I, Miyajima R (1969) Concerted inhibition and its reversal by end products of aspartate kinase in brevibacterium flavum. J Biochem 65(6):849–859

Szkopinska A (2000) Ubiquinone. Biosynthesis of quinone ring and its isoprenoid side chain. Intracellular localization. Acta Biochim Pol 47(2):469–480

Wang ZF, Huang YL, Rathman JF, Yang ST (2002) Lecithin-enhanced biotransformation of cholesterol to androsta-1, 4-diene-3, 17-dione and androsta-4-ene-3, 17-dione. J Chem Technol Biotechnol 77:1349–1357

Wu ZF, Du GC, Chen J (2003) Effects of dissolved oxygen concentration and DO-stat feeding strategy on CoQ(10) production with Rhizobium radiobacter. World J Microbiol Biotechnol 19(9):925–928

Wu Z-f, Du G-c, Chen J (2005) Effects of culture conditions on coenzyme Q(10) production by Rhizobium radiobacter by metabolic flux analysis. Weishengwu Xuebao 45(2):231–235

Yen HW, Chiu CH (2007) The influences of aerobic-dark and anaerobic-light cultivation on CoQ(10) production by Rhodobacter sphaeroides in the submerged fermenter. Enzyme Microb Technol 41(5):600–604

Zahiri HS, Yoon SH, Keasling JD, Lee SH, Kim SW, Yoon SC, Shin YC (2006) Coenzyme Q(10) production in recombinant Escherichia coli strains engineered with a heterologous decaprenyl diphosphate synthase gene and foreign mevalonate pathway. Metab Eng 8(5):406–416

Zhang DW, Li Z, Wang FH, Shrestha B, Tian PF, Tan TW (2007a) Expression of various genes to enhance ubiquinone metabolic pathway in Agrobacterium tumefaciens. Enzyme Microb Technol 41:772–779

Zhang DW, Shrestha B, Li ZP, Tan TW (2007b) Ubiquinone-10 production using Agrobacterium tumefaciens dps gene in Escherichia coli by coexpression system. Mol Biotechnol 35(1):1–14

Zhang DW, Shrestha B, Niu WN, Tian PF, Tan TW (2007c) Phenotypes and fed-batch fermentation of ubiquinone-overproducing fission yeast using pp t1 gene. J Biotechnol 128(1):120–131

Zhong W, Fang J, Liu H, Wang X (2009) Enhanced production of CoQ(10) by newly isolated Sphingomonas sp ZUTE03 with a coupled fermentation-extraction process. J Ind Microbiol Biotechnol 36(5):687–693

Acknowledgment

This study was supported by the Science and Technology Department of Zhejiang Province of PR China under Grant No. 2007C23035, for which the authors are grateful.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhong, W., Wang, W., Kong, Z. et al. Coenzyme Q10 production directly from precursors by free and gel-entrapped Sphingomonas sp. ZUTE03 in a water-organic solvent, two-phase conversion system. Appl Microbiol Biotechnol 89, 293–302 (2011). https://doi.org/10.1007/s00253-010-2876-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-010-2876-9