Abstract

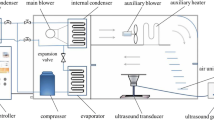

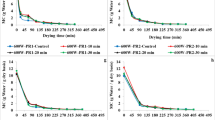

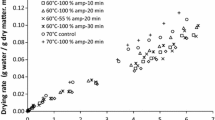

The study aims at reveal the enhanced effect of ultrasound on heat pump drying (HPD) process. Carrot was used as experimental material to determine its water removal, conversion and distribution during ultrasound-enhanced HPD. Carrots were dried at HPD temperatures of 40, 50, 60 °C and ultrasound powers of 0, 40, 80 W. Scanning electron microscopy (SEM) and low-field nuclear magnetic spectroscopy (LF-NMR) were applied to analyze the moisture distribution conditions status and moisture migration of carrot under 5 different drying conditions. The results showed that it displayed apparent strengthening effect by applying contact ultrasound (CU) during HPD, and higher temperature and CU power could obviously promote dehydration process. The SEM results revealed that the intensification effect of ultrasound and the increase of temperature could cause the improvement of micropores’ number inside carrot slices, which was conducive to the migration of internal moisture. LF-NMR analysis illustrated that the largest content of free water was removed first in CU-HPD process and the removal speed was accelerated with the increasing of drying temperature and ultrasound power. The immobilized water rose first and then fell, while the bound water hardly changed. Magnetic resonance imaging results could visually demonstrate the change and migration of water inside carrot slices, and CU had a strengthening effect on HPD, but this intensifying effect reduced significantly with the propagation of ultrasound in carrot slices. Therefore, CU application during HPD could achieve positive effect on water migration and moisture removal.

Similar content being viewed by others

Data availability

The data that support the finding of this study can be obtained from the corresponding author upon reasonable request.

References

Haworth F, Cleaver TJ, Bray JM (2015) The Effects of different manurial treatments on the yield and Mineral composition of carrots. J Hortic Sci 41(4):299–310. https://doi.org/10.1080/00221589.1966.11514178

Xanyar M, Yuhao D, Golshan M (2020) Impact of three different dehydration methods on nutritional values and sensory quality of dried broccoli, oranges, and carrots. Foods 9(10):1464–1464. https://doi.org/10.3390/foods9101464

Elżbieta W, Małgorzata S, Jarosław P et al (2019) Effect of biostimulant application and long-term storage on the nutritional value of carrot. Hortic Bras 37(4):451–457. https://doi.org/10.1590/s0102-053620190414

Wang X, Zhang X, Hong H et al (2021) Non-destructive quantitative analysis of carotene content in carrots using Raman spectroscopy. Eur Food Res Technol 1–9. https://doi.org/10.1007/S00217-021-03788-W

Esmail AS, P D A (2017) Nutritional and therapeutic importance of Daucus carota- A review. IOSR J Pharm (IOSRPHR) 07(02):72–88. https://doi.org/10.9790/3013-0702017288

Datt SK, Swati K, Singh TN et al (2012) Chemical composition, functional properties and processing of carrot-a review. J Food Sci Technol 49(1):22–32. https://doi.org/10.1007/s13197-011-0310-7

Hg R, Satish K, Shafiq A (2016) Microwave drying of fruits and vegetables: a fourth generation drying technology. J Community Health Manage 2(2):85–88

Smith WL (1962) Chemical Treatments to reduce Postharvest spoilage of fruits and vegetables. Bot Rev 28(3):411–445. https://doi.org/10.1007/BF02868689

Zhaofeng M, Xiangna C, Yin L et al (2022) Effect of electrohydrodynamics on hot air drying characteristics of fruits and vegetables. Sustain Energy Technol Assess 53(PC). https://doi.org/10.1016/J.SETA.2022.102716

Fugui D, Z G Y W (2016) Vacuum freeze-drying rate of fruits and vegetables based on lattice boltzmann method. Editorial Office of Transactions of the Chinese Society of Agricultural Engineering 32(14):258–264

Fakhreddin S (2021) Recent applications of heat pump dryer for drying of fruit crops: a review. Int J Fruit Sci 21(1):546–555. https://doi.org/10.1080/15538362.2021.1911746

Sagar VR, Suresh Kumar P (2010) Recent advances in drying and dehydration of fruits and vegetables: a review. J Food Sci Technol 47(1):15–26. https://doi.org/10.1007/s13197-010-0010-8

Hawlader MNA, Perera CO, Tian M (2005) Properties of modified atmosphere heat pump dried foods. J Food Eng 74(3):392–401. https://doi.org/10.1016/j.jfoodeng.2005.03.028

Song X, Hu H, Zhang B (2016) Drying characteristics of chinese Yam (Dioscorea opposita Thunb.) By far-infrared radiation and heat pump. J Saudi Soc Agricultural Sci 17(3):290–296. https://doi.org/10.1016/j.jssas.2016.05.008

Huihan X, Yunhong L, Linge G et al (2020) Effect of ultrasonic power on drying process and quality properties of far-infrared radiation drying on potato slices. Food Sci Biotechnol 29(1):93–101. https://doi.org/10.1007/s10068-019-00645-1

Qiaolan S, Xiaojie Y, Long Z et al (2022) Effects of vacuum ultrasonic infiltration and combined drying on rehydration quality of ginger (Zingiber officinale Roscoe). Ind Crops Prod. https://doi.org/10.1016/J.INDCROP.2022115381

Hills BP, Nott KP (1999) NMR studies of water compartmentation in carrot parenchyma tissue during drying and freezing. Appl Magn Reson 17(4):521–535. https://doi.org/10.1007/BF03162084

Hills BP, Remigereau B (1997) NMR studies of changes in subcellular water compartmentation in parenchyma apple tissue during drying and freezing. Int J Food Sci Technol 32(1):51–61. https://doi.org/10.1046/j.1365-2621.1997.00381.x

Fanyi Z, Weidong S, Jiaming K et al (2022) Detection of moisture content in salted sea cucumbers by hyperspectral and low field nuclear magnetic resonance based on deep learning network framework. Food Res Int 156:111174–111174. https://doi.org/10.1016/J.FOODRES.2022-111174

Jie P, Lifang Y, Mengmei W et al (2022) Evaluation of processing mechanism in Astragali Radix by low-field nuclear magnetic resonance and magnetic resonance imaging. PLoS ONE 17(3):0265383. https://doi.org/10.1371/JOURNAL.PONE.0265383

Yingying Z, Ronghua J, Feifei M et al (2021) Moisture variation analysis of the green plum during the drying process based on low-field nuclear magnetic resonance. J Food Sci 86(12):1537–1547. https://doi.org/10.1111/1750-3841.15955

Izli N, Izli G, Taskin O (2017) Drying kinetics, colour, total phenolic content and antioxidant capacity properties of kiwi dried by different methods. J Food Meas Charact 11(1):64–74. https://doi.org/10.1007/s11694-016-9372-6

Liu YH, Miao S, Wu JY et al (2014) Drying and quality characteristics of Flos†•Lonicerae in Modified Atmosphere with Heat Pump System. J Food Process Eng 37(1):37–45. https://doi.org/10.1111/jfpe.12057

Liu Y, Sun C, Lei Y et al (2019) Contact ultrasound strengthened far-infrared radiation drying on pear slices: Effects on drying characteristics, microstructure, and quality attributes. Drying Technol 37(6):745–758. https://doi.org/10.1080/07373937.2018.1458317

Norhaida H, Ang T, Kismurtono WL et al (2020) M, Effect of air temperature and velocity on the drying characteristics and product quality of Clinacanthus nutans in heat pump dryer. IOP Conference Series Earth and Environmental Science 462(1):012052. https://doi.org/10.1088/1755-1315/462/1/012052

Qian Z, Fangxin W, Zepeng Z et al (2020) Effect of ultrasonic far-infrared synergistic drying on the characteristics and qualities of wolfberry (Lycium barbarum L). Ultrason Sonochem 89:106134–106134. https://doi.org/10.1016/J.ULTSONCH.2022.106134

Nowacka M, Wiktor A, Śledź M et al (2012) Drying of ultrasound pretreated apple and its selected physical properties. J Food Eng 113(3):427–433. https://doi.org/10.1016/j.jfoodeng.2012.06.013

Liu Y, Zeng Y, Hu X et al (2020) Effect of Ultrasonic Power on Water removal Kinetics and Moisture Migration of Kiwifruit slices during contact Ultrasound intensified Heat Pump Drying[J]. Food and Bioprocess Technology: An International Journal 13(6):430–441. https://doi.org/10.1007/s11947-019-02401-z

Mongpraneet S, Abe T, Tsurusaki T (2002) Accelerated drying of welsh onion by far infrared radiation under vacuum conditions. J Food Eng 55(2):147–156. https://doi.org/10.1016/S0260-8774(02)00058-4

Kaur BP, Sharanagat VS, Nema PK (2015) Fundamental of drying. Fundamentals & Applications, Drying Technologies for Foods

Zhang B, Li M, Qiao Y et al (2020) Potential use of low-field nuclear magnetic resonance to determine the drying characteristics and quality of Arctium lappa L. in hot-blast air. https://doi.org/10.1016/j.lwt.2020.109829. LWT 132(prepublish)

Marques JPM, Rutledge DN, Ducauze CJ (1991) Low resolution pulse nuclear magnetic resonance study of water equilibration in dried carrots. Int J Food Sci Technol 26(2):173–183. https://doi.org/10.1111/j.1365-2621.1991.tb01153.x

Shi F, Li Y, Wang L et al (2018) Measurement of moisture transformation and distribution in Tricholoma matsutake by low field nuclear magnetic resonance during the hot-air drying process. J Food Process Preserv 42(3):13565. https://doi.org/10.1111/jfpp.13565

Li X, Ma LZ, Tao Y et al (2012) Low Field-NMR in Measuring Water mobility and distribution in beef granules during drying process. Adv Mater Res 1914(550–553):550–553. https://doi.org/10.4028/www.scientific.net/AMR.550-553.3406

Krishnamurthy K, Khurana HK, Soojin J et al (2008) Infrared heating in Food Processing: an overview. Compr Rev Food Sci Food Saf 7(1):2–13. https://doi.org/10.1111/j.1541-4337.2007.00024.x

Song P, Xu J, Ma HN et al (2016) Analysis on moisture transport in process of rice soaking using low field nuclear magnetic resonance and its imaging. Trans Chin Soc Agricultural Eng 32(17):274–280. https://doi.org/10.11975/j.issn.1002-6819.2016.17.036

Xi H, Liu Y, Guo L et al (2020) Effect of ultrasonic power on drying process and quality properties of far-infrared radiation drying on potato slices. Food Sci Biotechnol 29(1):93–101. https://doi.org/10.1007/s10068-019-00645-1

Acknowledgements

The authors are thankful to the financial supporting from the Science and Technology Research Project of Henan (212102110080).

Funding

he Science and Technology Research Project of Henan,212102110080,Yunhong Liu

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest statement

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Zhong, J., Han, M. et al. Drying characteristics and moisture migration of ultrasound enhanced heat pump drying on carrot. Heat Mass Transfer 59, 2255–2266 (2023). https://doi.org/10.1007/s00231-023-03412-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-023-03412-5