Abstract

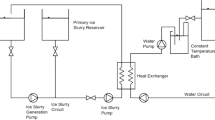

The heat transfer characteristics and particle size distribution (PSD) characteristics of ice slurry in double-tube heat exchanger (DTHE) are experimentally investigated. An experimental microscopic observation device is used to characterize the PSD of ice slurry. Experimental ice slurry PSDs are compared to classical normal, log-normal, Weibull and Gamma distributions, and the results match basically to log-normal distribution. The effects of flow rate, ice mass fraction and water temperature on the PSD and heat transfer coefficient of ice slurry are analyzed. The results showed that the heat transfer coefficient of ice slurry hc increases linearly with the increase of flow rate. The higher the water temperature and ice mass fraction, the larger hc, especially in the high flow rate region. After heat exchange, the peaks of PSD curves shift to the left and the range of PSD is significantly narrowed. The water temperature rises from 25℃ to 40℃, the differences in Sauter diameter (∆d32) can be increased by approximately 2 times. In addition, increasing the ice mass fraction can cause the increase of the Sauter diameter (d32) and decrease of ∆d32. The increase of flow rate leads to the decrease of ∆d32, which is caused by the insufficient heat exchange of ice slurry. These studies can give some help to further improve the heat transfer mechanism of ice slurry.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available on request from the corresponding author, upon reasonable request.

Abbreviations

- A :

-

surface area, m2

- C c :

-

comparison criteria

- c p :

-

specific heat capacity, J kg-1 K-1

- d, D :

-

diameter, m

- d 32 :

-

Sauter average particles size, m

- F :

-

function

- f :

-

the direct measurement parameters

- h :

-

heat transfer coefficient, W·m-2·K-1

- m :

-

weigh, kg

- N :

-

nature number

- Nu :

-

Nusselt number

- P :

-

pressure, Pa

- Pr :

-

Prandtl number

- PDF :

-

probability density function

- Q :

-

volumetric flow rate, m3 h-1

- Re :

-

Reynolds number

- T :

-

temperature, K

- T LM :

-

logarithmic mean temperature difference, K

- U :

-

flow rate, m·s-1

- δ:

-

uncertainty, %

- λ:

-

Thermal conductivity, W·m-1·K-1

- ρ:

-

density, kg·m-3

- χ:

-

mass friction,

- c:

-

cold fluid

- j:

-

index relative to crystal number

- h:

-

hot fluid

- id:

-

inner diameter

- in:

-

inlet

- od:

-

outer diameter

- out:

-

outlet

- w:

-

wall

References

Gao YG, Ning YL, Wu CZ, Xu MH, Akhtar S, Mujumdar AS, Sasmito AP (2023) Experimental investigation of producing ice slurry with water using opposed-nozzle impinging jet method. Appl Therm Eng 219:119568

Zhang C, Yang LW, Lin WY, Wei J, Chen JX, Ma ZJ (2021) Experimental investigation and life-cycle cost analysis of a cold storage enhanced vacuum cooling system using ice slurry. Sustain Energy Techn 45:101074

Li SF, Liu ZH, Wang XJ (2019) A comprehensive review on positive cold energy storage technologies and applications in air conditioning with phase change materials. Appl Energy 255:113667

Kumar A, Yadav SK, Mahato A, Kumar A (2019) On-demand intermittent ice slurry generation for subzero cold thermal energy storage: Numerical simulation and performance analysis. Appl Therm Eng 161:114081

Kauffeld M, Gund S (2019) Ice slurry-History, current technologies and future developments. Int J Refrig 99:264–271

Mi S, Cai LL, Ma KB, Liu ZQ (2018) Investigation on flow and heat transfer characteristics of ice slurry without additives in a plate heat exchanger. Int J Heat Mass Transf 127:11–20

Singh R, Kachhwaha SS (2016) Heat transfer and pressure drop analysis of chilled water and ice slurry in a plate heat exchanger. J Therm Sci Eng Appl 8:011020

Illán F, Viedma A (2012) Heat exchanger performance modeling using ice slurry as secondary refrigerant. Int J Refrig 35:1275–1283

Wang JH, Battaglia F, Wang SG, Zhang TF, Ma ZJ (2019) Flow and heat transfer characteristics of ice slurry in typical components of cooling systems: a review. Int J Heat Mass Transf 141:922–939

Cai LL, Mi S, Luo C, Liu ZQ (2022) Numerical investigation on heat and mass transfer characteristics of ice slurry in pulsating flow. Int J Heat Mass Transf 189:122722

Ma F, Zhang P, Shi XJ (2018) Investigation of thermo-fluidic performance of phase change material slurry and energy transport characteristics. Appl Energy 227:643–654

Onokoko CL, Galanis N, Poncet S, Poirier M (2019) Heat transfer of ice slurry flows in a horizontal pipe: a numerical study. Int J Therm Sci 142:54–67

Delahaye A, Fournaison L, Guilpart J (2010) Characterisation of ice and THF hydrate slurry crystal size distribution by microscopic observation method. Int J Refrig 33:1639–1647

Kauffeld M, Kawaji M, Egolf PW (2005) Handbook on ice slurries-fundamental and engineering. International Institute of Refrigeration, Paris

Van der Sman RGM (2016) Phase field simulations of ice crystal growth in sugar solutions. Int J Heat Mass Transf 95:153–161

Shimada W, Furukawa S (2018) Rapid growth of ice crystal dendrite tips in dilute solution of trehalose. J Cryst Growth 493:25–29

Pronk P, Hansen TM, Ferreira CAI, Witkamp GJ (2005) Time-dependent behavior of different ice slurries during storage. Int J Refrig 28:27–36

Zhao TL, Liu ZQ, Xu AX, He NP (2014) Numerical simulation of evolution of ice crystal size distribution during storage. J Cent South Univ (Science Technology) 10:3651–3656

Xu AX, Liu ZQ, Zhao TL, Wang XX (2015) Factors influencing dynamics evolution of ice crystals during ice slurry storage. J Cent South Univ (Science Technology) 46:3138–3144

Tang YF, Liu ZQ, Wang XX, Kang W, Zhang JY (2017) Effects of stirring action on ice crystal size evolution during storage. J Cent South Univ (Science Technology) 48:1376–1383

Kumano H, Hirata T, Hagiwara Y, Tamura F (2012) Effects of storage on flow and heat transfer characteristics of ice slurry. Int J Refrig 35:122–129

Cai LL, Liu ZQ, Mi S, Luo C, Ma KB, Xu AX, Yang S (2019) Investigation on flow characteristics of ice slurry in horizontal 90° elbow pipe by a CFD-PBM coupled model. Adv Powder Technol 30:2299–2310

Schultz R, Cole R (1979) Uncertainty analysis in boiling nucleation. AIChE Symp Ser 75:32–39

Peng ZB, Yuan ZL, Liang KF, Cai J (2008) Ice slurry formation in a cocurrent liquid-liquid flow. Chin J Chem Eng 16:552–557

Pronk P, Infante Ferreira CA, Witkamp GJ (2005) A dynamic model of Ostwald ripening in ice suspensions. J Cryst Growth 275:1355–1361

Clarke MA, Bishnoi PR (2004) Determination of the intrinsic rate constant and activation energy of CO2 gas hydrate decomposition using in-situ particle size analysis. Chem Eng Sci 59:2983–2993

Acknowledgement

This work is supported by Research Foundation of Natural Science Foundation of Xinjiang Uygur Autonomous Region (No.2022D01F39, No.2022D01A251), China University of Petroleum-Beijing at Karamay (NO.XQZX20230006, NO.XQZX20220013).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• The PSD evolution of ice slurry in DTHE is experimentally investigated.

• Log-normal distribution can well characterize the PSD of ice slurry.

• The influence of ice mass fraction and flow rate on PSD is discussed.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mi, S., Lingling, C. & Huang, J. Experimental investigation on the particle size distribution characteristics of ice slurry in double-tube heat exchanger. Heat Mass Transfer 59, 2231–2240 (2023). https://doi.org/10.1007/s00231-023-03406-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-023-03406-3