Abstract

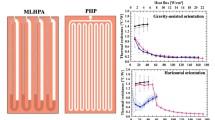

In this paper, a simple but detailed new theoretical model is developed for a thin loop heat pipe (LHP) to predict: the overall thermal resistance, the temperature distribution, the heat transfer rate, the heat leakage by conduction and the length of single and two-phase working fluid flows within the condenser. The theoretical results were confronted with experimental data of a mini flat LHP, manufactured using sintering and diffusion bonding processes. The working fluid used was water. A workbench, capable of simulating the actual operating conditions of a modern chip processor, with 1 cm2 of heat dissipating area, as found in smartphones and other electronic gadgets, was used to evaluate the LHP thermal performance. The tested LHP had dimensions of 76 x 60 x 1.6 mm3. The cold source was natural air convection to the surroundings. The device operated successfully in the orientations: horizontal, gravity-assisted, and against gravity. Tests were conducted until the evaporator reached 100°C, the limit temperature of electronics, resulting in overall thermal resistances of 0.37 °C/W, 0.47 °C/W and 0.44 °C/W, respectively. The model could successfully predict all steady-state operational parameters of the LHP with small deviations, proving to be suitable for designing new LHPs and other thin devices. The difference between predicted and measured resistances were within 5.64%, while between predicted and measured temperatures were within 3.30%. Lastly, the heat leak from the evaporator to the liquid line had a deviation of 16.62%. The LHP, although very thin, showed to be a good solution for cooling small electronic gadgets, such as mobile smartphones.

Similar content being viewed by others

Data Availability

The authors declare that the data supporting the findings of this study are available within the paper and its supplementary information files. Some supplementary data from the model and experimental results was uploaded.

Abbreviations

- A :

-

area [m2]

- B :

-

Chisholm parameter [-]

- c :

-

specific heat [J/kg°C]

- C :

-

Chisholm constant [-]

- d :

-

diameter [m]

- E :

-

Freidel parameter [-]

- f :

-

friction factor [-]

- F :

-

Freidel parameter [-]

- Fr :

-

Froude number [-]

- G :

-

mass velocity [kg/m2s]

- g :

-

gravity acceleration [m/s2]

- H :

-

Freidel parameter [-]

- h :

-

heat transfer coefficient [W/m2K]

- h lv :

-

latent heat of vaporization [J/kg]

- I :

-

current [A]

- J :

-

dimensionless vapor velocity [-]

- K :

-

permeability [m2]

- k :

-

thermal conductivity [W/m K]

- L :

-

length [m]

- ṁ:

-

mass flow rate [kg/s]

- n :

-

Chisholm parameter [-]

- Nu :

-

Nusselt number [-]

- p :

-

pressure [Pa]

- q :

-

heat transfer rate [W]

- \(q"\) :

-

heat flux [W/ m2]

- r:

-

radius [m]

- Ra :

-

Rayleigh number [-]

- Re :

-

Reynolds number [-]

- Rh :

-

hydraulic resistance [Pa.s/kg]

- R t :

-

thermal resistance [°C/W]

- t :

-

thickness [m]

- T :

-

temperature [°C]

- U :

-

voltage [V]

- V :

-

volume [m3]

- W :

-

width [m]

- We :

-

Weber number [-]

- X :

-

Martinelli parameter [-]

- Y :

-

Chisholm parameter [-]

- z :

-

distance [m]

- Z :

-

Shah’s correlating parameter

- α :

-

thermal diffusivity [m2/s]

- β :

-

coefficient of thermal expansion [1/K]

- ɛ:

-

porosity [%]

- Γ :

-

aspect ratio [-]

- Δ:

-

difference [-]

- δ:

-

uncertainty [-]

- ζ :

-

roughness [µm]

- θ :

-

contact angle [°]

- κ :

-

surface area ratio [-]

- μ :

-

dynamic viscosity [Pa.s]

- v :

-

kinematic viscosity [m2/s]

- ρ :

-

mass density [kg/m3]

- σ :

-

surface tension [N/m]

- υ:

-

specific volume [m3/kg]

- ϕ :

-

phase [-]

- φ :

-

channel aspect ratio [-]

- χ :

-

vapor quality

- ac :

-

active area

- amb :

-

ambient

- avg :

-

average

- b :

-

barrier

- c :

-

condenser

- cap :

-

capillarity

- ch :

-

channel

- cs :

-

cross-section

- eff :

-

effective

- eq :

-

equivalent

- ev :

-

evaporator

- hl :

-

heat leak

- h :

-

hydraulic

- i :

-

internal

- in :

-

inlet

- ini :

-

initial

- iso :

-

insulated

- l :

-

liquid

- ll :

-

liquid line

- lo :

-

liquid only

- p :

-

pressure

- r :

-

reduced

- sup :

-

superficial

- t :

-

total

- v :

-

vapor

- vg :

-

vapor grooves

- vo :

-

vapor inly

- w :

-

wick

- wf :

-

working fluid

- 1ϕ :

-

single-phase

- 2ϕ :

-

two-phase

- FR :

-

Filling Ratio [%]

- LHP :

-

Loop Heat Pipe

- TP :

-

two-phase mixture

References

Goncharov KA, Barantsevich VL, Orlov AA (2005) TAIS Ltd

Maydanik YF (2005) Loop heat pipes 25:635–657. https://doi.org/10.1016/j.applthermaleng.2004.07.010

Maydanik YF, Vershinin SV, Korukov MA, Ochterbeck JM (2004) Miniature loop heat pipes - a promising means for cooling electronics. Thermomech Phenom Electron Syst Proc Intersoc Conf 2:60–66. https://doi.org/10.1109/itherm.2004.1318253

Shioga T, Mizuno Y (2015) Micro loop heat pipe for mobile electronics applications. Annu IEEE Semicond Therm Meas Manag Symp 2015–April:50–55. https://doi.org/10.1109/SEMI-THERM.2015.7100139

Maydanik YF, Vershinin SV, Pastukhov VG, Fried SS (2010) Loop heat pipes for cooling systems of servers. IEEE Trans Compon Packag Technol 33:416–423. https://doi.org/10.1109/TCAPT.2009.2035514

Zimbeck W, Slavik G, Cennamo J, Kang S, Yun J, Kroliczek E (2008) Loop heat pipe technology for cooling computer servers, 2008 11th IEEE Intersoc. Conf. Therm. Thermomechanical phenom. Electron Syst I-THERM 19–25. https://doi.org/10.1109/ITHERM.2008.4544248

Singh R, Akbarzadeh A, Dixon C, Mochizuki M, Riehl RR (2007) Miniature loop heat pipe with flat evaporator for cooling computer CPU. IEEE Trans Compon Packag Technol 30:42–49. https://doi.org/10.1109/TCAPT.2007.892066

Zhou G, Li J, Lv L (2016) An ultra-thin miniature loop heat pipe cooler for mobile electronics. Appl Therm Eng 109:514–523. https://doi.org/10.1016/j.applthermaleng.2016.08.138

Domiciano KG, Krambeck L, Floréz JPM, Mantelli MBH (2022) Thin diffusion bonded flat loop heat pipes for electronics: fabrication, modelling and testing. Energy Convers Manag 255. https://doi.org/10.1016/j.enconman.2022.115329

Zhao R, Zhang Z, Zhao S, Cui H, Liu Z, Liu W (2021) Experimental study of flat-disk loop heat pipe with R1233zd(E) for cooling terrestrial electronics. Appl Therm Eng 197:117385. https://doi.org/10.1016/j.applthermaleng.2021.117385

Xiong K, Meng L, Wang S (2022) Design, fabrication, investigation and analysis of a novel flat evaporator loop heat pipe for cooling high heat flux server chips. Appl Therm Eng 201:117775. https://doi.org/10.1016/j.applthermaleng.2021.117775

Wu T, Wang T, Ma Z, Zhang Z, Liu W, Liu Z (2022) Experimental investigation on the start-up performance of a loop heat pipe with three flat disk evaporators combined. Appl Therm Eng 216:119128. https://doi.org/10.1016/j.applthermaleng.2022.119128

Tang H, Tang Y, Wan Z, Li J, Yuan W, Lu L, Li Y, Tang K (2018) Review of applications and developments of ultra-thin micro heat pipes for electronic cooling. Appl Energy 223:383–400. https://doi.org/10.1016/j.apenergy.2018.04.072

Zhou G, Li J, Jia Z (2019) Power-saving exploration for high-end ultra-slim laptop computers with miniature loop heat pipe cooling module. Appl Energy 239:859–875. https://doi.org/10.1016/j.apenergy.2019.01.258

Shioga T, Mizuno Y, Nagano H (2020) Operating characteristics of a new ultra-thin loop heat pipe. Int J Heat Mass Transf 151. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119436

Shioga T, Abe T, Nagano H (2020) Submillimeter-thick loop heat pipes fabricated using two-layer copper sheets for cooling electronic applications. Appl Therm Eng 181:116018. https://doi.org/10.1016/j.applthermaleng.2020.116018

Mizutani T, Watanabe N, Aso S, Sadakata K, Tanabe S, Nagano H (2022) Experimental and analytical investigation of a 0.3-mm-thick loop heat pipe for 10 W-class heat dissipation. Int J Heat Mass Transf 193:122950. https://doi.org/10.1016/j.ijheatmasstransfer.2022.122950

Bai L, Lin G, Zhang H, Wen D (2009) Mathematical modeling of steady-state operation of a loop heat pipe. Appl Therm Eng 29:2643–2654. https://doi.org/10.1016/j.applthermaleng.2008.12.040

Chernysheva MA, Vershinin SV, Maydanik YF (2007) Operating temperature and distribution of a working fluid in LHP. Int J Heat Mass Transf 50:2704–2713. https://doi.org/10.1016/j.ijheatmasstransfer.2006.11.020

Florez JPM, Mantelli MBH (2017) Thermal model for sintered cylindrical evaporators of loop heat pipes. J Thermophys Heat Transf 31:165–177. https://doi.org/10.2514/1.T4790

Zhang Z, Cui H, Zhao S, Zhao R, Wu T, Liu Z, Liu W (2023) Simulation of heat and mass transfer process in a flat-plate loop heat pipe and experimental comparison. Appl Therm Eng 220:119705. https://doi.org/10.1016/j.applthermaleng.2022.119705

Ramasamy NS, Kumar P, Wangaskar B, Khandekar S, Maydanik YF (2018) Miniature ammonia loop heat pipe for terrestrial applications: experiments and modeling. Int J Therm Sci 124:263–278. https://doi.org/10.1016/j.ijthermalsci.2017.10.018

Florez JPM, Mantelli MBH, Nuernberg GGV, Milanez FH (2014) Powder geometry based models for sintered media porosity and effective thermal conductivity. J Thermophys Heat Transf 28:507–517. https://doi.org/10.2514/1.T4206

Flórez JP, Mera ME, Chiamulera MBH, Mantelli (2017) Permeability model of sintered porous media: analysis and experiments. Heat Mass Transf Und Stoffuebertragung 53:3277–3285. https://doi.org/10.1007/s00231-017-2028-1

Mera JPF (2016) Heat and mass transfer analysis of a copper loop heat. Universidade Federal de Santa Catarina

Maydanik Y, Vershinin S, Chernysheva M, Yushakova S (2011) Investigation of a compact copper-water loop heap pipe with a flat evaporator. Appl Therm Eng 31:3533–3541. https://doi.org/10.1016/j.applthermaleng.2011.07.008

Holman JP (2011) Experimental methods for engineers, 8th ed., New York, USA, https://doi.org/10.1093/nq/s1-VIII.193.43-b

Florez JPM, Mantelli MBH, Nuernberg GGV (2013) Effective thermal conductivity of sintered porous media: Model and experimental validation. Int J Heat Mass Transf 66:868–878. https://doi.org/10.1016/j.ijheatmasstransfer.2013.07.088

Chi SW (1976) Heat pipe theory and practice: a sourcebook (series in thermal and fluids engineering). Hemisphere Pub Corp

Faghri A (2014) Heat Pipes: Review, Opportunities and Challenges. Front Heat Pipes 5. https://doi.org/10.5098/fhp.5.1

Li J, Peterson GP (2011) 3D heat transfer analysis in a loop heat pipe evaporator with a fully saturated wick. Int J Heat Mass Transf 54:564–574. https://doi.org/10.1016/j.ijheatmasstransfer.2010.09.014

Kandlikar SG (2006) Single-phase Liquid Flow in Minichannels and Microchannels, Heat Transf. Fluid Flow Minichannels Microchannels 87–136. https://doi.org/10.1016/B978-008044527-4/50005-0

Chisholm D (1967) A theoretical basis for the Lockhart-Martinelli correlation for two-phase flow. Int J Heat Mass Transf 10:1767–1778. https://doi.org/10.1016/0017-9310(67)90047-6

Milanez F, Mantelli MBH (2010) Heat transfer Limit due to pressure Drop of a two-phase Loop Thermosyphon. Heat Pipe Sci Technol An Int J 1:237–250. https://doi.org/10.1615/heatpipescietech.2011003082

Li J, Wang D, Bud Peterson GP (2011) A compact loop heat pipe with flat square evaporator for high power chip cooling. IEEE Trans Compon Packag Manuf Technol 1:519–527. https://doi.org/10.1109/TCPMT.2010.2099531

Hanlon MA, Ma HB (2003) Evaporation heat transfer in sintered porous media. J Heat Transfer 125:644–652. https://doi.org/10.1115/1.1560145

Taylor P, Shah MM (2009) An Improved and Extended General correlation for heat transfer during condensation in plain tubes. Hvac R Res 15:37–41

Cavallini A, Del Col D, Doretti L, Matkovic M, Rossetto L, Zilio C, Censi G (2006) Condensation in horizontal smooth tubes: a new heat transfer model for heat exchanger design. Heat Transf Eng 27:31–38. https://doi.org/10.1080/01457630600793970

Shah MM (2016) A correlation for heat transfer during condensation in horizontal mini/micro channels. Int J Refrig 64:187–202. https://doi.org/10.1016/j.ijrefrig.2015.12.008

Shah MM (2013) General correlation for heat transfer during condensation in plain tubes: further development and verification. ASHRAE Trans 119:3–11

Ali ME (2007) Natural convection heat transfer from horizontal rectangular ducts. J Heat Transfer 129:1195–1202. https://doi.org/10.1115/1.2739623

Garimella S (2006) Condensation in minichannels and microchannels. Heat transfer and fluid flow in minichannels and microchannels. Elsevier, pp 295–494

Acknowledgments

The authors acknowledge FAPESC (Fundação de Amparo à Pesquisa e Inovação do Estado de Santa Catarina) for providing scholarship (grant number 3003/2021) and CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico) for their financial support to the present research (grant number 423968/2018-1).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Domiciano, K.G., Krambeck, L., Mera, J.P.F. et al. Study of a new thin flat loop heat pipe for electronics. Heat Mass Transfer 59, 2035–2056 (2023). https://doi.org/10.1007/s00231-023-03381-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-023-03381-9