Abstract:

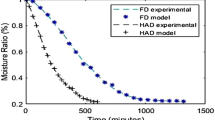

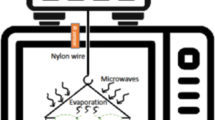

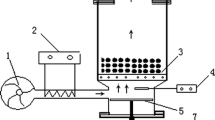

In order to explore the strengthening effect of contact ultrasound on cold air drying(CAD) of yam, contact ultrasound strengthened cold air drying (CUCAD) experiments were carried out. The effects of ultrasonic power and cold air temperature on drying characteristics, microstructure and effective moisture diffusivity were studied, and the drying process was simulated by BP, RBF, Elman and RNN neural network models. The results showed that increasing ultrasonic power and drying temperature could significantly shorten the drying time of yam, facilitate the formation and expansion of micropores, and improve the internal mass and heat transfer of material. With the decrease of water content, the drying rate gradually decreased. The prediction performance results of the four neural network models were compared, and the RNN network model could achieve the highest fitting accuracy for the prediction of CUCAD process of yam. Therefore, contact ultrasound could achieve a significant strengthening effect during CUCAD process.

Similar content being viewed by others

References

Awoyale W, Maziya-Dixon B, Sanni LO, Shittu TA (2016) Effect of water yam (Dioscoreaalata) flour fortified with distiller’s spent grain on nutritional, chemical, and functional properties. Food Sci Nutr 4(1):24–33

Li X, Liu XR, Yin Y, Yu HC, Zhang M, Jing HN, Ma YC, Xiong XL, Pang XY (2019) Transcriptomic analysis reveals key genes related to antioxidant mechanisms of Hylocereus undatus quality improving by trypsin during storage. Food Funct 10:8116–8128

Adebowale ARA, Wahab AB, Sobukola PO, Obadina AO, Kajihausa EO, Adegunwa OM, Sanni OL, Tomlins K (2018) The antinutritional and vitamin composition of high-quality yam flour as affected by yam specie, pretreatment, and drying method. Food Sci Nutr 6(8):1985–1990

Ju H, Law C, Fang X, Xiao H, Liu Y, Gao Z (2016) Drying kinetics and evolution of the sample’s core temperature and moisture distribution of yam slices (Dioscorea alata L.) during convective hot-air drying. Dry Technol 34(11):1297–1306

Barbosa AF, Sabaa-Srur DF, Soares Maia JG, Oliveira Sabaa-Srur AU (2016) Microbiological and sensory evaluation of Jambu (Acmella oleracea L.) dried by cold air circulation. Food Sci Technol 36(1):24–29

Wongsim K, Jamradloedluk J, Lertsatitthanakorn C, Siriamornpun S, Rungsiyopas M, Soponronnarit S (2015) Experimental performance of a thermoelectric heat-pump drying system for drying herbs. J Electron Mater 44(6):2142–2145

Li S, Chen SS, Han F, Xv Y, Sun H, Ma Z, Chen J, Wu W (2019) Development and optimization of cold plasma pretreatment for drying on corn kernels. J Food Sci 84(8):2181–2189

Zhang J, Liu Y, Sun Z, Bai X, Chen Y (2020) Drying characteristics and optimization of ultrasound-strengthened cold air drying combined with sequential far-infrared radiation drying on potato. J Food Process Pres 44(9):e14632

Chavan P, Sharma P, Sharma SR, Mittal TC, Jaiswal AK (2022) Application of high-intensity ultrasound to improve food processing efficiency: A review. Foods 11(1):122

Ozuna C, Alvarez-Arenas TG, Riera E, Carcel JA, Garcia-Perez JV (2014) Influence of material structure on air-borne ultrasonic application in drying. Ultrason Sonochem 21(3):1235–1243

Liu Y, Zeng Y, Hu X, Sun X (2020) Effect of ultrasonic power on water removal kinetics and moisture migration of kiwifruit slices during contact ultrasound intensified heat pump drying. Food Bioproc Tech 13(3):430–441

Tufekci S, Ozkal SG (2017) Enhancement of drying and rehydration characteristics of okra by ultrasound pre-treatment application. Heat Mass Transfer 53(7):2279–2286

Liu Y, Sun Y, Yu H, Yin Y, Li X, Duan X (2017) Hot air drying of purple-fleshed sweet potato with contact ultrasound assistance. Dry Technol 35(5):564–576

Bahmani A, Jafari SM, Shahidi SA, Dehnad D (2016) Mass transfer kinetics of eggplant during osmotic dehydration by neural networks. J Food Process Pres 40(5):815–827

Lertworasirikul S, Saetan S (2010) Artificial neural network modeling of mass transfer during osmotic dehydration of kaffir lime peel. J Food Eng 98(2):214–223

Figueroa-Garcia E, Farias-Cervantes VS, Chavez-Rodriguez AM (2021) Using artificial neural networks in prediction of the drying process of foods that are rich in sugars. Rev Mex Ing Quim 20(1):161–171

Nathan MH, Rafiee S, Aghbashlo M, Hosseinpour S, Mohtasebi SS (2015) Continuous real-time monitoring and neural network modeling of apple slices color changes during hot air drying. Food Bioprod Process 94:263–274

Bai J, Zhou C, Cai J, Xiao H, Gao Z, Ma H (2017) Vacuum pulsating drying characteristics and moisture content prediction of pumpkin flakes. Trans Chin Soc Agric Eng 33(17):290–297

Sarimeseli A, Coskun MA, Yuceer M (2014) Modeling microwave drying kinetics of thyme (Thymus Vulgaris L.) leaves using Ann methodology and dried product quality. J Food Process Pres 38(1):558–564

Guine RPF, Barroca MJ, Goncalves FJ, Alves M, Oliveira S, Mendes M (2015) Artificial neural network modelling of the antioxidant activity and phenolic compounds of bananas submitted to different drying treatments. Food Chem 168:454–459

Tian F, Liu Y, Huang J, Cao X, Xue S (2019) Potato ultrasound-strengthened cold air drying and quality characteristics. Food Sci 40(05):85–94

Gu R, Wan G, Tao C (2019) Anti-browning technology of fresh-cut Huai yam. Food Ind 40(12):161–165

Correa JLG, Braga AMP, Hochheim M, Silva MA (2012) The influence of ethanol on the convective drying of unripe, ripe, and overripe bananas. Dry Technol 30(8):817–826

Xu G, Gu Z, Xu J, Li H, Zhang X (2009) Study on carrot heat pump far infrared combined drying process. Food and Fermentation Industries 35(06):96–99

Murthy TPK, Manohar B (2014) Hot air drying characteristics of mango ginger: Prediction of drying kinetics by mathematical modeling and artificial neural network. J Food Sci Technol 51(12):3712–3721

Rodriguez O, Santacatalina JV, Simal S, Garcia-Perez JV, Femenia A, Rossello C (2014) Influence of power ultrasound application on drying kinetics of apple and its antioxidant and microstructural properties. J Food Eng 129:21–29

Ciurzynska A, Falacinska J, Kowalska H, Kowalska J, Galus S, Marzec A, Domian E (2021) The effect of pre-treatment (blanching, ultrasound and freezing) on quality of freeze-dried red Beets. Foods 10(1):132

Fan K, Zhang M, Mujumdar AS (2017) Application of airborne ultrasound in the convective drying of fruits and vegetables: A review. Ultrason Sonochem 39:47–57

Wiktor A, Sledz M, Nowacka M, Rybak K, Witrowa-Rajchert D (2016) The influence of immersion and contact ultrasound treatment on selected properties of the apple tissue. Appl Acoust 103:136–142

Garcia-Perez JV, Ortuno C, Puig A, Carcel JA, Perez-Munuera I (2012) Enhancement of water transport and microstructural changes induced by high-intensity ultrasound application on orange peel drying. Food Bioprocess Tech 5(6):2256–2265

Ashokkumar M (2015) Applications of ultrasound in food and bioprocessing. Ultrason Sonochem 25:17–23

Doymaz I, Kipcak AS, Piskin S (2015) Characteristics of thin-layer infrared drying of green bean. Czech J Food Sci 33(1):83–90

Lu X, Liu Y, Zhang D, Guo G, Li H, Ren G (2017) Effects of high humidity pretreatment on hot air drying characteristics and rehydration of Huai yam. Food & Machinery 33(11):147–151

Xi H, Liu Y, Guo L, Hu R (2020) Effect of ultrasonic power on drying process and quality properties of far-infrared radiation drying on potato slices. Food Sci Biotechnol 29(1):93–101

Chai H, Chen X, Zhao J (2019) Artificial neural network modeling for predicting wood moisture content in high frequency vacuum drying process. Forests 10(1):16

Yan Z (2015) Research and application on BP neural network algorithm. Proceedings of the 2015 International Industrial Informatics and Computer Engineering Conference 1444–1447

Cossu A, Carta A, Lomonaco V, Bacciu D (2021) Continual learning for recurrent neural networks: An empirical evaluation. Neural Netw 143:607–627

Liu L, Yu X (2019) Recurrent neural network (RNN) and its application research.Sci Technol Vision(32):54–55

Kaminski W, Strumillo P, Tomczak E (1998) Neurocomputing approaches to modelling of drying process dynamics. Dry Technol 16(6):967–992

Xi H, Liu Y, Wang Q, Li H, Li G, Zhao L (2019) Study on the drying characteristics and neural network model of potato enhanced by far-infrared radiation. Food & Machinery 35(02):123–128

Nazghelichi T, Kianmehr MH, Aghbashlo M (2011) Prediction of carrot cubes drying kinetics during fluidized bed drying by artificial neural network. J Food Sci Tech Mys 48(5):542–550

Huynh QK, Nguyen CN, Vo-Nguyen HP, Tran-Nguyen PL, Le PH, Le DKL, Nguyen VC (2021) Crack identification on the fresh Chilli (Capsicum) fruit destemmed system. J Sens 2021

Sholahudin S, Han H (2016) Simplified dynamic neural network model to predict heating load of a building using Taguchi method. Energy 115:1672–1678

Kujawa S, Niedbala G (2021) Artificial neural networks in agriculture. Agriculture-Basel 11(6):497

Liu W, Zhang M, Bhandari B, Yu D (2021) A novel combination of LF-NMR and NIR to intelligent control in pulse-spouted microwave freeze drying of blueberry.LWT-Food Sci Technol137

Calabretta R, Di Ferdinando A, Parisi D (2004) Ecological neural networks for object recognition and generalization. Neural Process Lett 19(1):37–48

Shi XW, Yang Y, Li ZY, Wang XY, Liu YH (2020) Moisture transfer and microstructure change of banana slices during contact ultrasound strengthened far-infrared radiation drying. Innov Food Sci Emerg 66:102537

Acknowledgements

The authors are thankful to the financial supporting from the College’s Innovation Talents Program in Henan (19HASTIT013) and the Henan Science and Technology Research Project (212102110080).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest statement

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Z., Wang, Y., Shi, Q. et al. Drying characteristics and neural network models of contact ultrasound strengthened cold air drying on yam. Heat Mass Transfer 59, 1109–1120 (2023). https://doi.org/10.1007/s00231-022-03323-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-022-03323-x